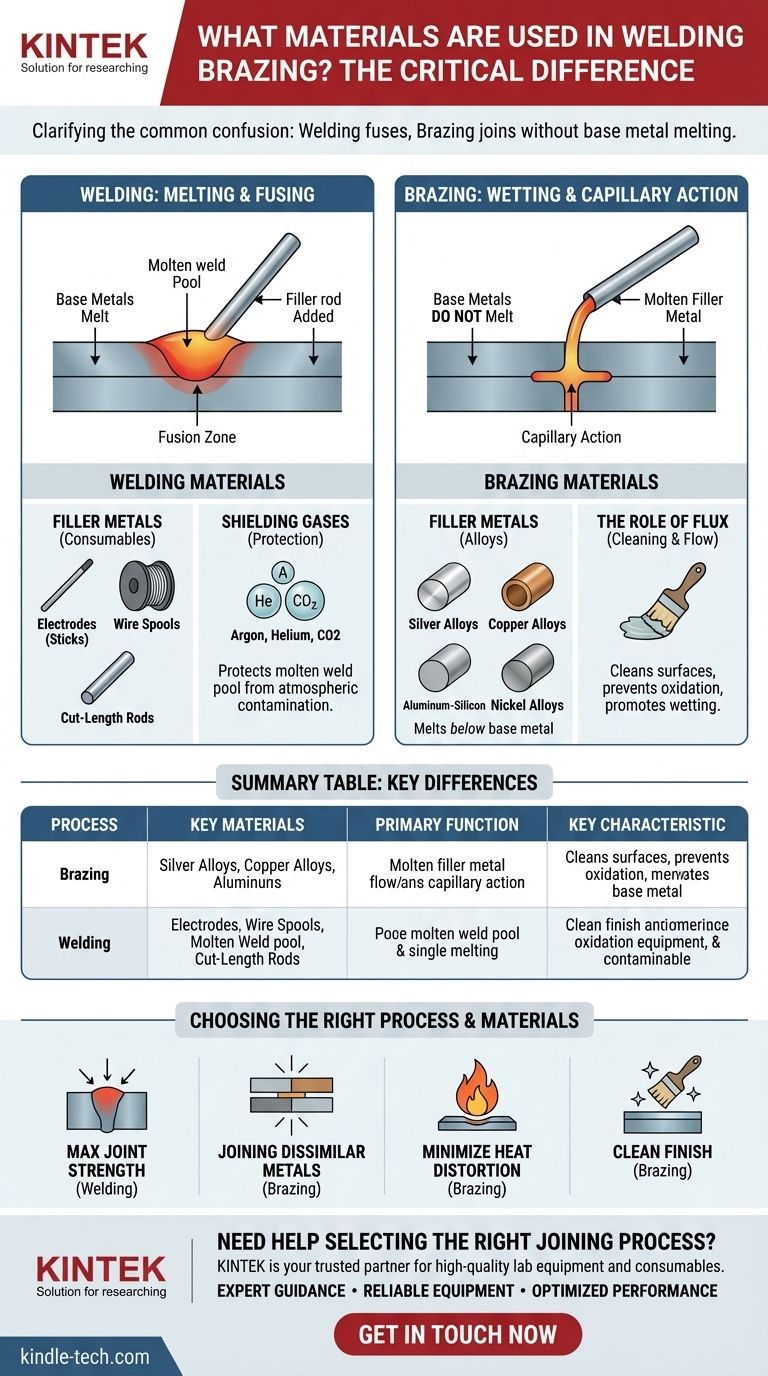

While the term "welding brazing" is not standard, it points to a common area of confusion between two distinct but related metal-joining processes: welding and brazing. The core difference lies in the materials used and how they interact with the parts being joined. Brazing uses a filler metal that melts at a lower temperature than the base metals, joining them like a high-strength glue, while welding melts the base metals themselves to fuse them together, often with a compatible filler.

The most critical distinction is this: in brazing, the base metal does not melt, only the filler metal does. In welding, the process is designed to melt and fuse the edges of the base metals, creating a single, continuous piece. This fundamental difference dictates the choice of all materials involved, from fillers to fluxes and shielding gases.

The Fundamental Difference: Melting vs. Wetting

Understanding the materials begins with understanding the core mechanism of each process. They achieve the same goal—joining metal—in fundamentally different ways.

How Welding Works

Welding joins materials by melting the workpieces at the joint. A molten pool is formed from the base metals, which cools to form a strong, fused bond.

Often, a filler material is added to this molten pool to add strength or fill gaps. The key principle is that the filler must be metallurgically compatible with the base metals, as they all mix together in a liquid state.

How Brazing Works

Brazing joins metals using a filler metal that has a melting point below that of the base metals being joined (specifically, above 450°C or 842°F). The base metals are heated, but they never melt.

The molten brazing filler flows between the closely fitted surfaces of the joint through a process called capillary action. It functions like a metallic adhesive, creating a metallurgical bond upon cooling without altering the base metals.

Materials Used in Brazing

Brazing relies on two key materials working in concert: a filler metal and a flux.

Brazing Filler Metals

Brazing filler metals are alloys designed with specific melting temperatures and flow characteristics. Common families include:

- Silver Alloys: Used for joining most ferrous and non-ferrous metals, excluding aluminum and magnesium. They offer high strength and ductility.

- Copper and Copper-Phosphorus Alloys: Primarily used for joining copper, brass, and bronze. The phosphorus acts as a fluxing agent when joining copper to copper, eliminating the need for separate flux.

- Aluminum-Silicon Alloys: Used specifically for brazing aluminum alloys. Their melting temperature is just below that of the aluminum base metals.

- Nickel Alloys: Chosen for high-temperature applications and joining stainless steels or heat-resistant alloys, offering superior strength and corrosion resistance.

The Role of Flux

Flux is a chemical compound applied to the joint before heating. Its purpose is to clean the surfaces, protect them from oxidation during heating, and help the molten filler metal "wet" and flow smoothly across the base metals. It is a critical material for a successful braze.

Materials Used in Welding

Welding materials, often called consumables, include filler metals and, in many processes, shielding gases.

Welding Filler Materials

The primary rule in welding is that the filler material must be compatible with the base metal. You weld steel with a steel filler rod and aluminum with an aluminum filler wire.

- Electrodes (Sticks): Used in Shielded Metal Arc Welding (SMAW), these are metal rods coated in flux. The flux burns to create a shielding gas and forms a slag layer over the finished weld to protect it as it cools.

- Wire Spools: Used in MIG (GMAW) and Flux-Cored (FCAW) welding. A machine continuously feeds this wire into the weld pool. Some wires are solid and require a separate shielding gas, while others have a flux core.

- Cut-Length Rods: Used in TIG (GTAW) welding. These are bare filler rods that the welder manually dips into the molten weld pool.

Shielding Gases

In MIG and TIG welding, shielding gas is a critical material fed through the welding torch. Its sole purpose is to protect the molten weld pool from oxygen, nitrogen, and water vapor in the atmosphere, which would otherwise contaminate and weaken the weld.

Common shielding gases include Argon, Helium, Carbon Dioxide (CO2), or various mixtures of these gases, selected based on the metal being welded and the desired performance.

Understanding the Trade-offs

Choosing between these processes is a matter of engineering trade-offs directly tied to the materials and their behavior.

Joint Strength and Temperature

Welding fuses the base metals, generally creating a joint that is as strong or stronger than the original material and can withstand very high temperatures. A brazed joint's strength and temperature limit are determined by the filler metal, which is inherently weaker and has a lower melting point than the base metal.

Impact on Base Metals

The intense, localized heat of welding creates a Heat-Affected Zone (HAZ), which can alter the mechanical properties, such as hardness and ductility, of the base metal surrounding the weld. Brazing uses much lower temperatures, distributing heat more broadly and minimizing thermal distortion or damage to the base metals.

Joining Dissimilar Metals

Brazing excels at joining dissimilar metals (e.g., copper to steel). Because the base metals don't melt, you only need to find a filler metal that is metallurgically compatible with both. Welding dissimilar metals is extremely difficult and often impossible due to incompatible melting points, chemistries, and expansion rates.

Process Complexity and Finish

Brazed joints are often cleaner, more precise, and require little to no post-process grinding or finishing. Welding can produce spatter and a rougher bead that frequently requires cleanup for cosmetic or functional reasons.

How to Choose the Right Process

Your project's goal will determine which process and materials are the correct choice.

- If your primary focus is maximum joint strength and high-temperature performance: Choose welding, ensuring the filler metal is compatible with your base metal.

- If your primary focus is joining dissimilar metals or minimizing heat distortion: Choose brazing, selecting a filler metal with the appropriate flow temperature and strength for your application.

- If your primary focus is joining thin, delicate, or heat-sensitive components: The lower heat input of brazing makes it the safer and more controllable choice.

- If your primary focus is a clean, finished appearance with minimal post-processing: Brazing often provides a neater joint that is ready for use right after cooling.

Understanding the function of these materials empowers you to select the process that ensures the integrity, strength, and performance of your final component.

Summary Table:

| Process | Key Materials | Primary Function | Key Characteristic |

|---|---|---|---|

| Brazing | Filler Metal (e.g., Silver, Copper alloys), Flux | Joins metals via capillary action without melting the base metals. | Base metals do not melt; lower process temperature. |

| Welding | Filler Metal (e.g., Electrodes, Wire), Shielding Gas (e.g., Argon) | Fuses base metals by melting them together. | Base metals melt; creates a Heat-Affected Zone (HAZ). |

Need Help Selecting the Right Joining Process and Materials?

Choosing between brazing and welding is critical for your project's strength, durability, and performance. The right materials and equipment make all the difference.

KINTEK is your trusted partner for all metal-joining needs. We specialize in providing high-quality lab equipment and consumables, including the precise heating systems essential for brazing and material testing equipment to validate your welds.

Let us help you achieve superior results:

- Expert Guidance: Get advice on selecting the right filler metals, fluxes, and processes for your specific materials and application.

- Reliable Equipment: Access the tools you need for consistent, high-quality joins.

- Optimized Performance: Ensure the integrity and longevity of your components.

Contact our experts today for a consultation and discover how KINTEK can support your laboratory's success.

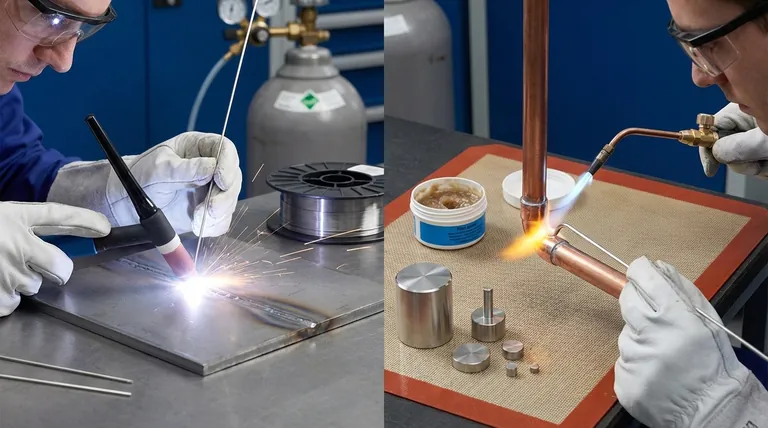

Visual Guide

Related Products

- Assemble Lab Cylindrical Press Mold

- Polygon Press Mold for Lab

- Ball Press Mold for Lab

- Assemble Square Lab Press Mold for Laboratory Applications

- Square Bidirectional Pressure Mold for Lab Use

People Also Ask

- What role do high-temperature pressure molds play in SiCp/Al fabrication? Enhancing Densification and Thermal Uniformity

- What is the function of press molds during the preparation of SiCf/Ti-43Al-9V composites? Achieve Structural Precision

- Why are a laboratory hydraulic press and precision molds required for pressing MAX phase green bodies? - Expert Guide

- What is the impact factor of powder metallurgy progress? A 2022 Analysis & Context

- What are the functions of a cylindrical pelleting mold and a hydraulic press in LATP ceramics? Create High-Density Pellets