In principle, sieving is used to separate any mixture composed of solid particles of different sizes. This physical separation technique is effective for heterogeneous mixtures, such as separating stones from sand, sifting lumps from flour, or grading different sizes of construction aggregate. The only requirement is a discernible difference in the physical size of the components.

Sieving is a method of mechanical separation that works exclusively on heterogeneous mixtures with a significant particle size differential. It cannot be used to separate substances that are dissolved or components that are uniformly sized.

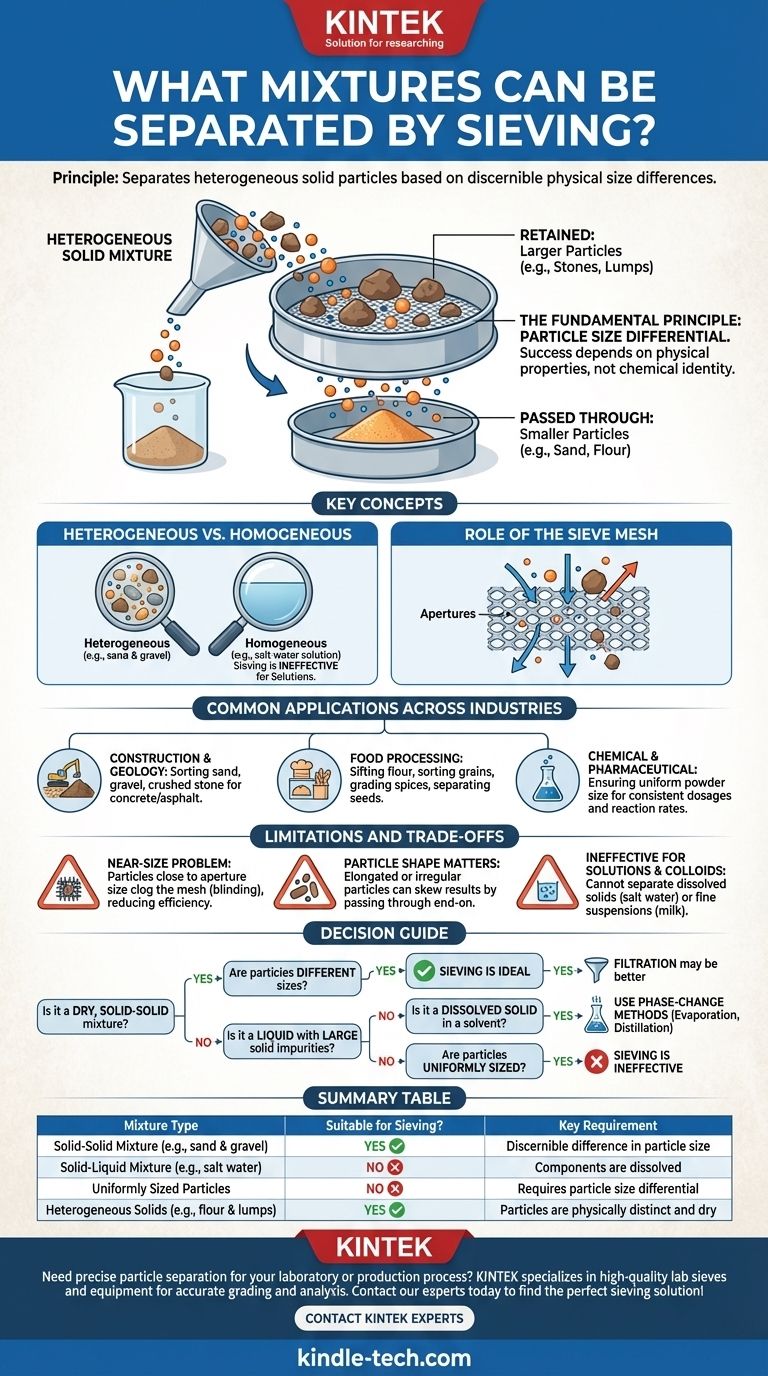

The Fundamental Principle: Particle Size Differential

Sieving is one of the most intuitive methods of separation. Its success hinges entirely on the physical properties of the mixture's components, not their chemical identities.

What is a Heterogeneous Mixture?

For sieving to work, the mixture must be heterogeneous, meaning its components are physically distinct and not uniformly distributed. You can see the individual parts.

A mixture of sand and gravel is heterogeneous; you can identify both components. In contrast, salt dissolved in water forms a homogeneous mixture (a solution), where the salt particles are broken down to the ionic level and cannot be separated with a physical screen.

The Role of the Sieve Mesh

A sieve is simply a screen with a mesh of a specific size. The holes in this mesh are called apertures.

When a mixture is passed over the sieve, particles smaller than the apertures fall through, while particles larger than the apertures are retained on top. This is the entire mechanism of separation.

Common Examples Across Industries

This simple principle is applied in countless fields to sort, grade, and purify materials.

- Construction & Geology: Sieves are used to analyze soils and to sort sand, gravel, and crushed stone into specific grades required for creating concrete and asphalt.

- Food Processing: Flour is sifted to remove clumps and bran. Sieving is also used to sort grains, separate seeds from fruit pulp, and grade spices.

- Chemical & Pharmaceutical: Powders are sieved to ensure a uniform particle size, which is critical for predictable reaction rates, proper mixing, and creating consistent dosages in tablets.

Understanding the Limitations and Trade-offs

While powerful, sieving is not a universal solution. Understanding its limitations is key to using it effectively.

The "Near-Size" Problem

Separation becomes inefficient when a significant portion of the particles are very close in size to the sieve's apertures. These "near-size" particles can clog or blind the mesh, blocking other particles from passing through and dramatically reducing efficiency.

Particle Shape Matters

Sieving assumes particles are roughly spherical. However, elongated or irregularly shaped particles can skew results. A long, needle-like particle might pass through a mesh end-on, even if it is much larger than the aperture in other dimensions.

Ineffective for Solutions and Colloids

It is crucial to remember that sieving is a purely physical process. It cannot separate a dissolved solid from a liquid (like salt from water) or components of a very fine suspension known as a colloid (like milk). These require methods like evaporation, distillation, or ultrafiltration.

Making the Right Choice for Your Goal

Use this guide to determine if sieving is the correct method for your specific separation task.

- If your primary focus is sorting a dry, solid-solid mixture: Sieving is the ideal and most direct method, provided the particles are different sizes.

- If your primary focus is removing large solid impurities from a liquid: Sieving can work for coarse materials like removing leaves from water, but filtration is the more appropriate term for finer separations.

- If your primary focus is separating a dissolved solid from a solvent: Sieving will fail completely; you must use a phase-change method like evaporation or distillation.

Ultimately, understanding the simple rule of particle size is the key to effectively applying sieving as a separation tool.

Summary Table:

| Mixture Type | Suitable for Sieving? | Key Requirement |

|---|---|---|

| Solid-Solid Mixture (e.g., sand & gravel) | Yes | Discernible difference in particle size |

| Solid-Liquid Mixture (e.g., salt water) | No | Components are dissolved (requires filtration/evaporation) |

| Uniformly Sized Particles | No | Requires a particle size differential to separate |

| Heterogeneous Solids (e.g., flour & lumps) | Yes | Particles are physically distinct and dry |

Need precise particle separation for your laboratory or production process?

KINTEK specializes in high-quality lab sieves and equipment designed for accurate, reliable grading and analysis of solid materials. Whether you're in R&D, quality control, or production, our sieves ensure consistent results.

Contact our experts today to find the perfect sieving solution for your specific application!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- How does size matter in the process of sieving? Master the Geometry of Particle Separation

- Why is sieving necessary for mixed FeCrAl-based composite powders? Key to Superior Quality Control

- What is the importance of sieving in chemistry? Master Particle Size for Precise Control

- Why is 200-mesh sieving performed on ground powders? Ensure Peak Efficiency in Magnesium & Zinc Borate Synthesis

- Which solids can be separated from a solution by sieving? Understanding the Limits of Sieving

- How many ways can sieve analysis be carried out? Choose the Right Method for Accurate Results

- What is powder sieving? A Guide to Accurate Particle Size Separation

- What are standard sieves in pharmaceutical? Precision Instruments for Particle Size Control