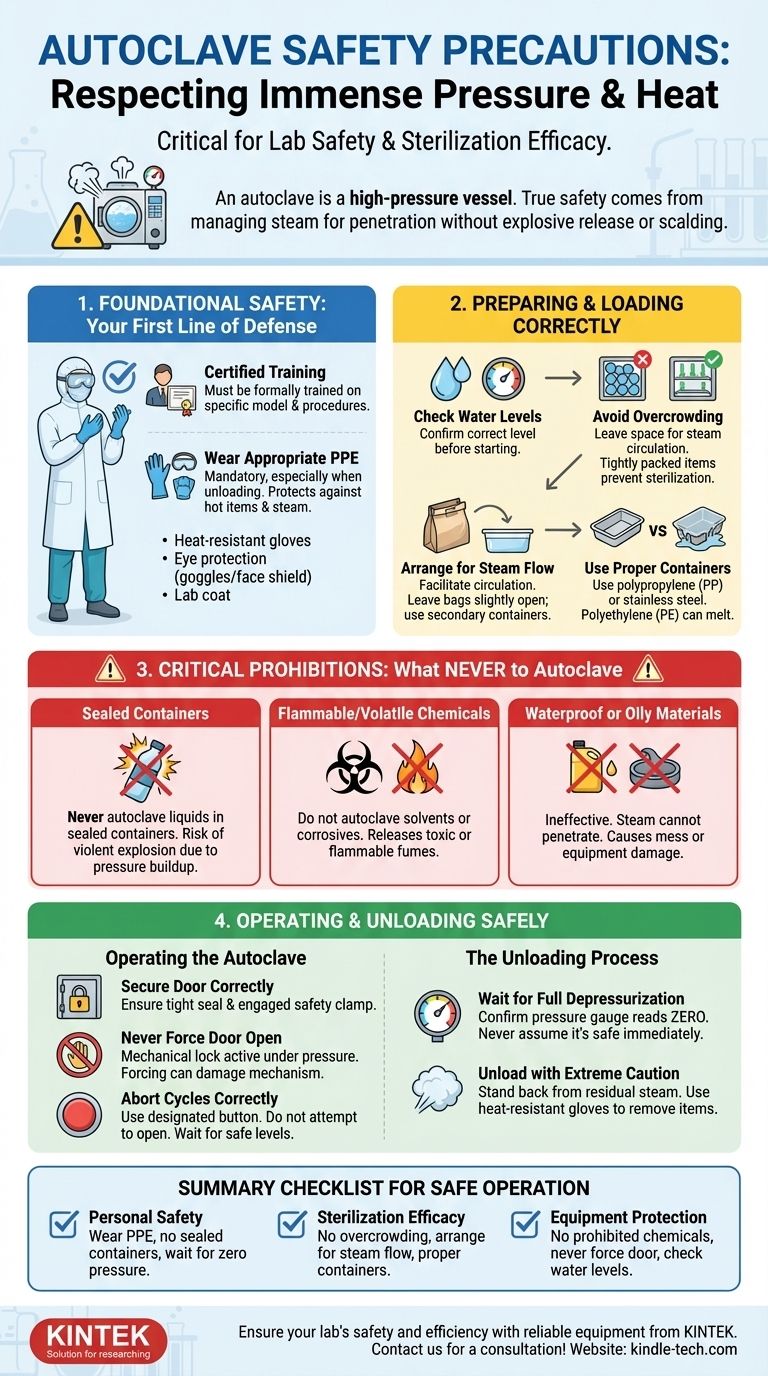

The most critical autoclave precautions involve respecting the immense pressure and heat it generates. This means always wearing appropriate Personal Protective Equipment (PPE), never loading sealed containers, and ensuring you have been properly trained on the specific model you are using before you begin. Safe operation hinges on understanding how to prepare materials for effective sterilization and how to handle them safely after the cycle is complete.

An autoclave is not a simple oven; it is a high-pressure vessel designed to kill microorganisms with superheated steam. True safety comes from managing this steam—ensuring it can penetrate the load effectively while preventing the explosive release of pressure or scalding heat.

Foundational Safety: Your First Line of Defense

Before you even approach the machine, certain non-negotiable prerequisites must be met. Ignoring these foundational steps is the most common source of accidents.

Start with Certified Training

No one should operate an autoclave without being formally trained by a qualified person. You must understand the specific operating procedures, safety features, and emergency protocols for the exact model in your lab.

Wear Appropriate PPE

Personal Protective Equipment is mandatory, especially when unloading. The contents will be extremely hot and may release scalding steam.

- Heat-resistant gloves are essential for handling hot items.

- Eye protection (goggles or a face shield) guards against splashes of superheated water.

- A lab coat protects your body and clothing from contact with hot surfaces.

Preparing and Loading the Autoclave Correctly

Proper loading is not just about efficiency; it's a critical safety and efficacy measure. The goal is to allow steam to circulate freely and penetrate every surface.

Check Water Levels

Every autoclave requires a specific amount of water to generate steam. Always confirm the water level is correct according to the manufacturer's user manual before starting a cycle.

Avoid Overcrowding the Chamber

Do not overfill the autoclave. Tightly packed items prevent steam from reaching all surfaces, leading to incomplete sterilization. Leave ample space between all items.

Arrange Items for Steam Flow

Place items in a way that facilitates steam circulation. Bags should be left slightly open, and items should be placed in secondary containers to catch any spills.

Use Proper Containers

Never use materials that can melt or obstruct steam. Polyethylene (PE) trays can melt and damage the autoclave. Use polypropylene (PP) or stainless steel trays for secondary containment instead.

Critical Prohibitions: What NEVER to Autoclave

Certain materials create extreme hazards when subjected to the heat and pressure of an autoclave. Placing these items inside can result in explosions, toxic fumes, or equipment damage.

Sealed Containers

Never autoclave liquids in a sealed container. As the liquid heats up, pressure builds inside the container with nowhere to escape, creating a significant risk of the container exploding violently.

Flammable or Volatile Chemicals

Do not autoclave items containing solvents, corrosives, or other volatile chemicals. Heating these substances can release toxic or flammable fumes, creating a hazardous environment in the lab.

Waterproof or Oily Materials

Materials like oil and grease are waterproof and cannot be penetrated by steam. Attempting to autoclave them is ineffective and can result in a simple mess or equipment damage.

Operating the Autoclave Safely

During the cycle, the autoclave is a locked, high-pressure system. Understanding its operational state is key to preventing injury.

Secure the Door Correctly

Ensure the autoclave door is closed tightly and the safety clamp is properly engaged. A poor seal will prevent the machine from reaching the required pressure and could release hot steam.

Never Force the Door Open

During operation, the door is secured by a mechanical locking mechanism that will not disengage until internal pressure has returned to a safe level. Forcing the door can permanently damage the mechanism and risk a sudden, explosive release of steam.

Abort Cycles Correctly

If you suspect a problem, use the designated controller button or emergency stop to abort the cycle. Do not attempt to open the door. Wait until both the temperature and pressure have returned to safe, ambient levels.

The Unloading Process: Managing Post-Cycle Hazards

The end of the cycle is one of the most dangerous phases. Even though the pressure has normalized, the contents are still extremely hot.

Wait for Full Depressurization

Confirm that the chamber pressure gauge reads zero before attempting to open the door. Never assume the cycle's end tone means it is safe to open immediately.

Unload with Extreme Caution

Stand back when you first unlatch the door, as residual steam and hot air will rush out. Use your heat-resistant gloves to remove items one by one, and place them on a heat-proof surface to cool.

A Simple Checklist for Safe Operation

Use this framework to ensure you cover all critical safety points for every run.

- If your primary focus is personal safety: Always wear the correct PPE, never load sealed containers, and wait for complete depressurization before opening the door.

- If your primary focus is effective sterilization: Ensure you do not overcrowd the chamber, arrange items to promote steam flow, and use appropriate secondary containers.

- If your primary focus is protecting the equipment: Never load prohibited chemicals or plastics that can melt, and never force the door mechanism.

Mastering these precautions ensures that the autoclave remains a reliable tool for your research, not a source of risk.

Summary Table:

| Safety Focus Area | Key Precaution |

|---|---|

| Personal Safety | Wear appropriate PPE (gloves, eye protection, lab coat). Never load sealed containers. Wait for full depressurization before opening. |

| Sterilization Efficacy | Do not overcrowd the chamber. Arrange items for proper steam flow. Use proper secondary containers (e.g., polypropylene). |

| Equipment Protection | Never autoclave flammable chemicals or materials that can melt. Never force the door open. Check water levels before starting. |

Ensure your lab's safety and efficiency with reliable equipment from KINTEK. Proper sterilization is critical for your research integrity and team safety. KINTEK specializes in high-quality lab equipment and consumables, including autoclaves and accessories designed for safe, effective operation. Let our experts help you select the right tools for your specific laboratory needs. Contact us today to learn more and get a consultation!

Visual Guide

Related Products

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast High Pressure Laboratory Autoclave Sterilizer 16L 24L for Lab Use

People Also Ask

- What role does an autoclave play in remediation experiments? Ensure Precision by Eliminating Biological Noise

- What is the function of laboratory autoclaves in SCWR research? Predict Material Compatibility and Corrosion Kinetics

- What experimental conditions do stainless steel autoclaves provide for PCT-A leaching? Optimize Phosphate Glass Testing

- What role does an autoclave play in the acid treatment for microalgae disruption? Unlock High-Yield Cell Pretreatment

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization