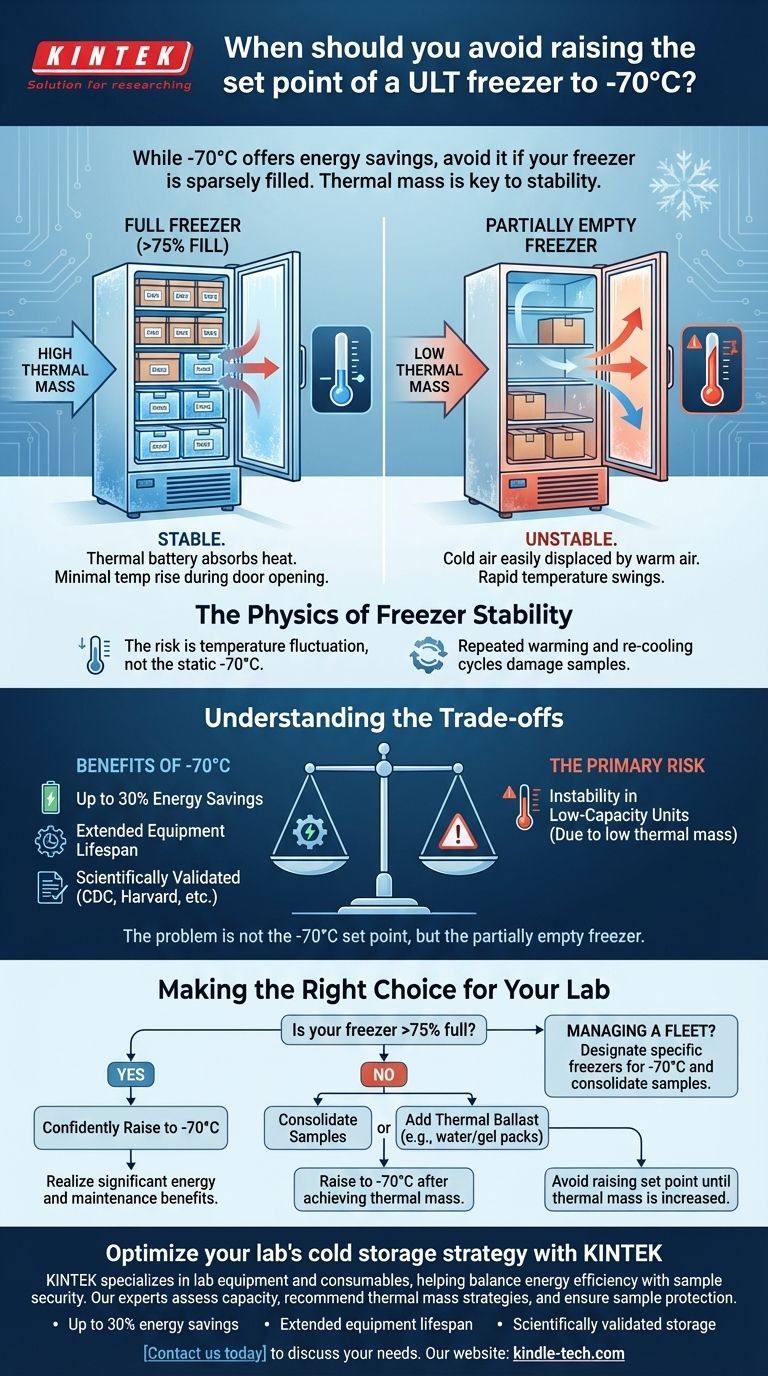

While adjusting your ULT freezer from -80°C to -70°C is a proven strategy for significant energy savings, this change is not advisable in all situations. You should avoid raising the set point if the freezer is not sufficiently full. A sparsely filled unit lacks the necessary thermal mass to buffer against temperature fluctuations when the door is opened, which can lead to rapid warming events that may compromise sample integrity over time.

The decision to raise a ULT freezer's set point hinges on one critical factor: thermal mass. A fully stocked freezer provides the necessary thermal mass to maintain a stable -70°C, while a partially empty one risks significant and potentially damaging temperature swings during routine access.

The Physics of Freezer Stability

At these ultralow temperatures, stability is paramount. The primary risk is not the static -70°C temperature itself, but the fluctuation above it during real-world use.

Why a Full Freezer is More Stable

A freezer packed with frozen samples, boxes, and racks has high thermal mass. This mass of frozen material acts like a thermal battery, holding the cold temperature.

When the door is opened, this large frozen mass effectively absorbs the heat from the incoming warmer air, minimizing any significant rise in the freezer's internal temperature.

The Risk of a Partially Full Freezer

In a sparsely filled freezer, there is very little thermal mass to buffer against temperature change. The internal volume is mostly just cold air.

When the door opens, warm, moist ambient air rushes in and rapidly displaces the cold air. Without a significant frozen mass to absorb this thermal load, the internal temperature can swing upwards dramatically and quickly.

The Impact of Temperature Swings

For many biological samples, it is the repeated warming and re-cooling cycles—not the baseline storage temperature—that cause the most damage.

A quick rise from -70°C to -60°C or even -55°C during a routine door opening can be more detrimental than stable storage at -70°C. This is the core risk you must mitigate.

Understanding the Trade-offs

The move to -70°C is a balance between proven efficiency gains and a single, manageable operational risk.

Benefit: Significant Energy and Equipment Savings

Adjusting a ULT freezer from -80°C to -70°C can reduce energy consumption by up to 30%.

This reduces the strain on the freezer's compressors, prolonging the unit's lifespan, decreasing the likelihood of failure, and reducing maintenance costs.

Benefit: Scientifically Validated Storage

The -80°C standard is widely considered a historical artifact of marketing rather than a scientific necessity. There is no broad scientific evidence demonstrating the superiority of -80°C over -70°C for the vast majority of sample types.

Leading institutions worldwide, including the CDC, Harvard, Genentech, and AstraZeneca, have successfully transitioned to a -70°C standard, validating its safety and efficacy.

The Primary Risk: Instability in Low-Capacity Units

The only significant operational risk in moving to -70°C is thermal instability. This risk is not inherent to the temperature itself but is a direct consequence of operating a freezer with low thermal mass.

Therefore, the problem is not the -70°C set point, but the partially empty freezer.

Making the Right Choice for Your Lab

Your decision should be based on your freezer's current fill level and your ability to manage its thermal mass.

- If your freezer is consistently more than 75% full: You can confidently raise the set point to -70°C to realize significant energy and maintenance benefits.

- If your freezer is partially empty: Avoid raising the set point unless you can consolidate samples with another lab to create a full freezer or add thermal ballast (such as sealed containers of water or gel packs) to fill empty space.

- If you are managing a fleet of freezers: Designate specific freezers for -70°C operation and consolidate appropriate samples into them to maximize efficiency across your facility.

By understanding the fundamental role of thermal mass, you can optimize your cold storage strategy for both efficiency and sample security.

Summary Table:

| Freezer Condition | Recommended Action | Key Reason |

|---|---|---|

| More than 75% full | Raise set point to -70°C | High thermal mass provides stability for energy savings |

| Partially empty (low fill) | Avoid raising set point | Lack of thermal mass causes risky temperature swings |

| Can consolidate samples | Raise set point after consolidation | Achieves necessary thermal mass for stable operation |

Optimize your lab's cold storage strategy with KINTEK

Are you managing ULT freezers and seeking to balance energy efficiency with sample security? KINTEK specializes in lab equipment and consumables, providing solutions tailored to your laboratory's unique needs. Our experts can help you assess your freezer capacity, recommend thermal mass strategies, and ensure your valuable samples remain protected while reducing operational costs.

Let us help you achieve:

- Up to 30% energy savings with proper freezer management

- Extended equipment lifespan through reduced compressor strain

- Scientifically validated storage conditions for your samples

Contact us today to discuss how we can support your lab's cold storage optimization and overall efficiency goals!

Visual Guide

Related Products

- 708L Ultra Low Temperature Freezer High Performance Laboratory Freezer

- 208L Advanced Precision Laboratory Ultra Low Temperature Freezer for Cold Storage

- 608L Essential Laboratory Ultra Low Temperature Freezer For Critical Sample Preservation

- 808L Precision Laboratory Vertical Ultra Low Temperature Freezer

- 938L Vertical Ultra Low Temperature Freezer for Advanced Laboratory Storage

People Also Ask

- What temperature ranges are typically associated with ultra-low temperature freezers? Preserve Samples from -40°C to -86°C

- What are the key features to look for in an ultra-low temperature freezer for mRNA vaccine storage? Essential Features for Absolute Vaccine Integrity

- How are advancements in compressor technology and refrigerant fluids improving ULT freezers? Boost Efficiency & Cut Costs

- What are ultra-low temperature freezers designed for? Preserving Your Most Valuable Biological Samples

- What is an ultra-low temperature freezer? Protect Your Most Valuable Biological Samples