The better choice is not a rod mill or a ball mill, but the right mill for your specific goal. A ball mill is superior for producing very fine, powder-like materials. In contrast, a rod mill excels at creating a coarser, more uniform product and is specifically designed to avoid the over-grinding that creates excessive fine particles, known as slimes.

Your decision hinges on one critical factor: the final particle size you need. Ball mills use point-to-point impact to pulverize material into fine powders, while rod mills use line-to-line impact to create a more controlled, coarser grind with a narrow size distribution.

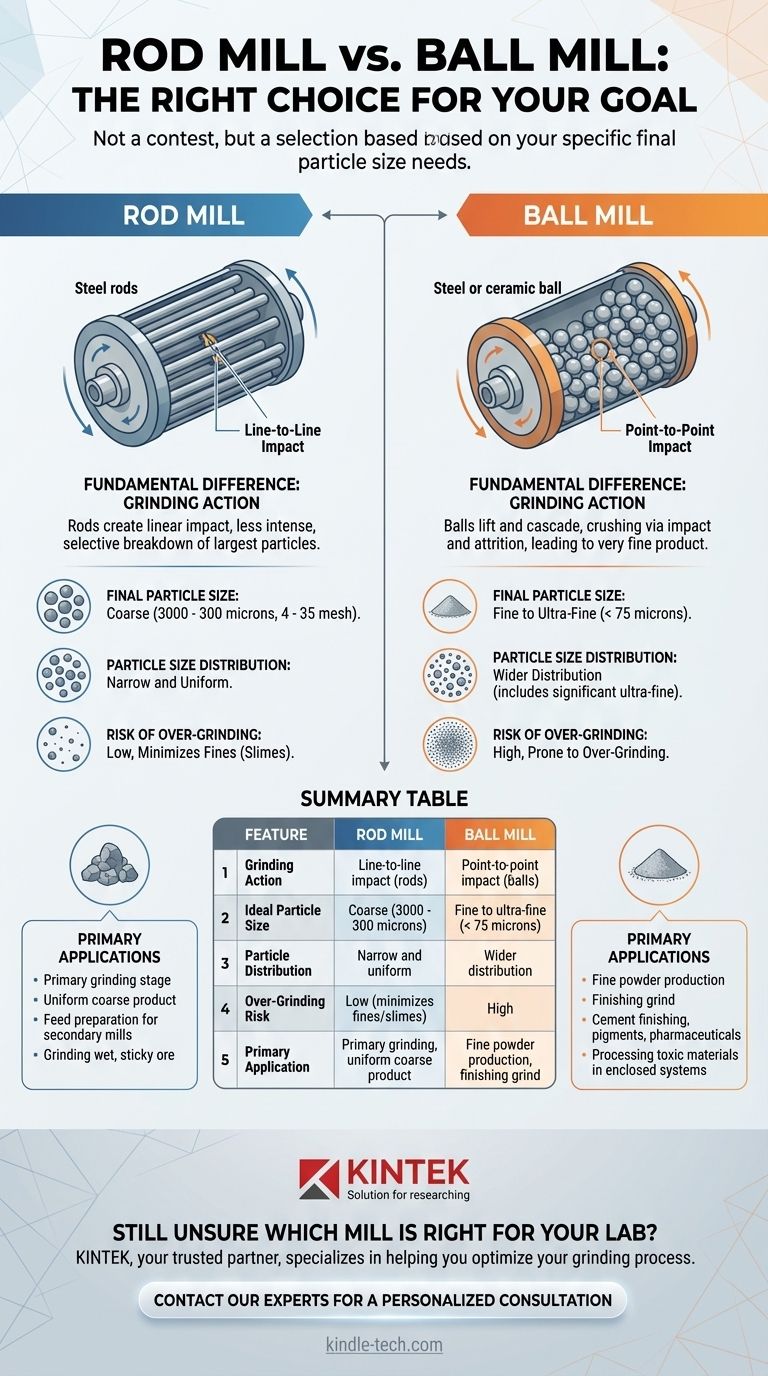

The Fundamental Difference: Grinding Action

To select the right equipment, you must first understand how each mill works. Their distinct internal mechanics dictate their performance and ideal applications.

Ball Mills: Point-to-Point Impact

A ball mill is a rotating drum filled with spherical grinding media (steel or ceramic balls). As the drum turns, the balls are lifted and then cascade down, crushing the material through impact and attrition.

This action creates countless points of high-pressure contact. This is highly effective at breaking down particles of all sizes within the mill, leading to a very fine final product.

Rod Mills: Line-to-Line Impact

A rod mill uses heavy steel rods that run the length of the mill instead of balls. As the drum rotates, these rods create a cascading, tumbling motion.

The grinding action occurs along the lines of contact between the rods. This linear impact is less intense but more selective, preferentially breaking down the largest particles while leaving smaller ones untouched, preventing over-grinding.

Comparing Key Performance Characteristics

The differences in grinding action lead to significant variations in output. Understanding these is key to making an informed choice.

Final Particle Size

A ball mill is the industry standard for fine and ultra-fine grinding. It can reliably reduce materials to particle sizes of 10-75 microns or even finer, making it suitable for creating powders.

A rod mill is designed for coarse grinding. It typically produces a product in the range of 3000 to 300 microns (4 to 35 mesh) and is not efficient for creating fine powders.

Particle Size Distribution

The output of a rod mill has a very narrow and uniform particle size distribution. Because the rods target the largest particles first, the final product contains very few oversized particles and minimal unwanted fines.

A ball mill naturally produces a wider distribution of particle sizes, including a significant percentage of ultra-fine particles.

Risk of Over-Grinding

The rod mill's primary advantage is its ability to minimize over-grinding. The linear impact and screening action of the rods protect smaller particles, preventing the creation of slimes that can complicate downstream processes.

The ball mill's intense, point-contact action makes it much more prone to over-grinding. While desirable for some applications, this can be a major inefficiency in others.

Understanding the Trade-offs and Applications

Each mill is an engineered solution for a different set of problems. Choosing the wrong one leads to inefficiency, poor product quality, and increased operational costs.

When to Choose a Ball Mill

A ball mill is the correct choice when your final product must be a fine powder. Its ability to handle a wide variety of materials, including highly abrasive ones, makes it extremely versatile.

Common applications include cement finishing, pigment production, and manufacturing fine powders for pharmaceuticals. The enclosed system is also ideal for processing toxic materials safely.

When to Choose a Rod Mill

A rod mill is superior when you need a uniform, coarse product with a controlled top size and minimal fines. It is often used to prepare feed for a subsequent grinding stage, such as a ball mill.

This makes it a cornerstone in mineral processing circuits where precise particle size is critical for separation processes like flotation or magnetic separation.

The Efficiency Factor

For a large reduction ratio (e.g., turning 20mm feed into a 100-micron powder), using a single, large ball mill can be inefficient.

A more effective strategy is often a two-stage process: a rod mill for the initial coarse grind, followed by a ball mill to efficiently finish the material into a fine powder.

Making the Right Choice for Your Goal

Ultimately, the equipment must serve your process objective. Use these guidelines to make a clear decision.

- If your primary focus is producing a very fine powder (< 75 microns): The ball mill is the definitive and superior choice for this task.

- If your primary focus is creating a uniform, coarse product with minimal fines: The rod mill is specifically designed for this outcome and will outperform a ball mill.

- If your primary focus is preparing feed for a secondary grinding circuit: A rod mill is almost always the most efficient first stage to control particle size for the next step.

- If your primary focus is grinding a wet, sticky ore: A rod mill is often preferred as it is less likely to become clogged than a ball mill.

By understanding these distinct grinding mechanisms, you can select the mill that acts as a precise tool for your specific material and desired outcome.

Summary Table:

| Feature | Rod Mill | Ball Mill |

|---|---|---|

| Grinding Action | Line-to-line impact (rods) | Point-to-point impact (balls) |

| Ideal Particle Size | Coarse (3000 - 300 microns) | Fine to ultra-fine (< 75 microns) |

| Particle Distribution | Narrow and uniform | Wider distribution |

| Over-Grinding Risk | Low (minimizes fines/slimes) | High |

| Primary Application | Primary grinding, uniform coarse product | Fine powder production, finishing grind |

Still Unsure Which Mill is Right for Your Lab?

Selecting the correct grinding equipment is critical for your process efficiency and final product quality. KINTEK, your trusted partner in laboratory equipment, specializes in helping you make the right choice.

We provide high-quality ball mills and rod mills tailored to your specific material and particle size goals. Our experts can help you:

- Optimize your grinding process for maximum efficiency.

- Achieve precise particle size distributions for better downstream results.

- Select the perfect mill or a combination for multi-stage grinding.

Don't leave your results to chance. Contact our grinding experts today for a personalized consultation and ensure you have the right tool for the job.

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Single Horizontal Jar Mill

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

People Also Ask

- What is the primary function of a planetary ball mill? Unlock Nano-Scale Precision for Composite Polymer Electrolytes

- What is the function of a high-energy planetary ball mill? Unlock Nanoscale Precision in Powder Metallurgy

- What is the primary function of a planetary ball mill for LLZTO targets? Achieving High-Energy Pulverization

- What function does a planetary ball mill perform in all-solid-state silver batteries? Optimize Electrode Interfaces

- What affects ball mill efficiency? Optimize Grinding Speed, Media, and Material for Peak Performance

- Why is it necessary to perform mechanical ball milling of high-entropy alloy powders under an inert gas atmosphere?

- What is the function of a high-energy ball mill in Li3YCl6 preparation? Optimize Your Solid Electrolyte Synthesis

- What is the primary purpose of using stainless steel grinding balls in ball milling copper and CNTs?