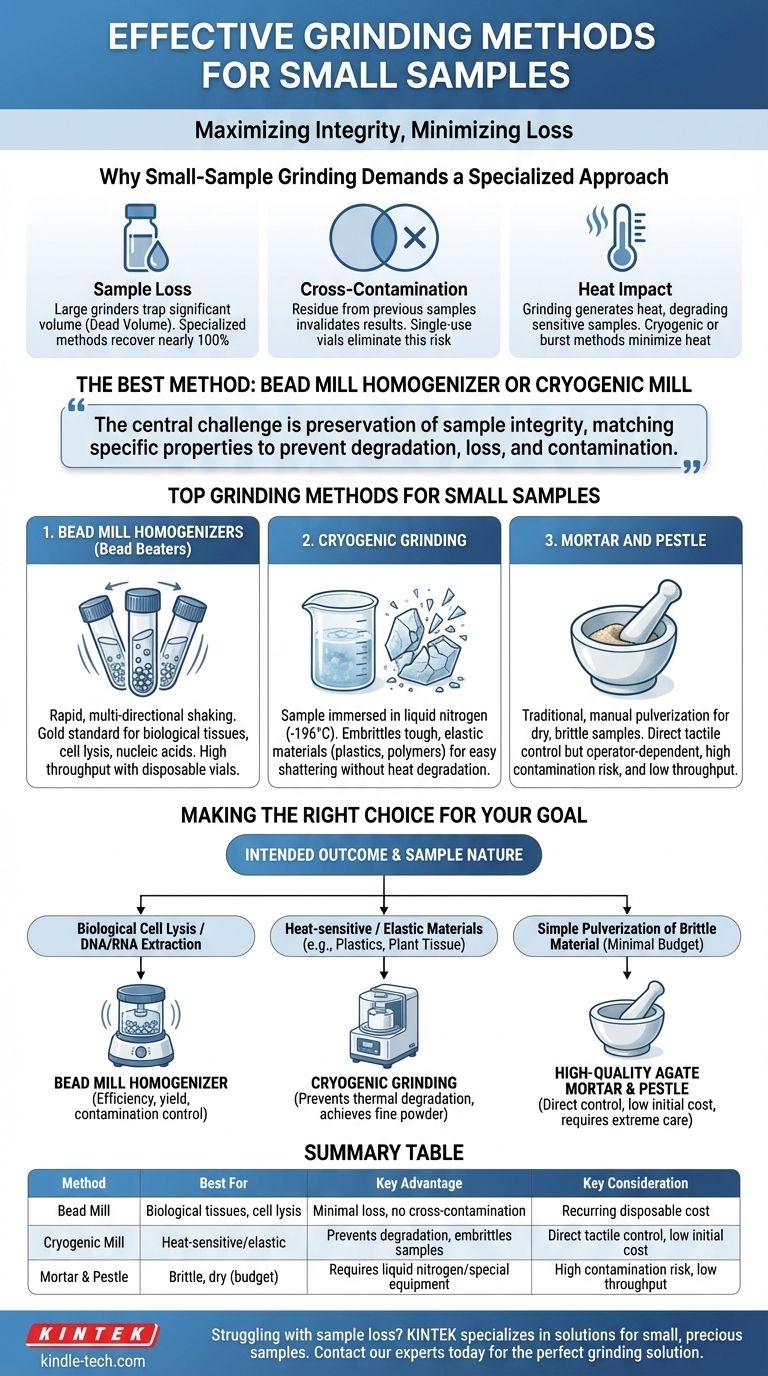

For small samples, the most effective grinding method is a bead mill homogenizer or, for heat-sensitive or tough materials, a cryogenic mill. These methods are specifically designed to handle low volumes (from micrograms to a few grams) with minimal sample loss, high reproducibility, and a significantly reduced risk of cross-contamination compared to traditional bulk grinding techniques.

The central challenge in grinding small samples is not just particle size reduction, but the preservation of the sample's integrity. The best method is one that matches your sample's specific properties to prevent degradation, loss, and contamination, ensuring the quality of your downstream analysis.

Why Small-Sample Grinding Demands a Specialized Approach

Standard grinding equipment is built for bulk processing, making it unsuitable for precious or limited-quantity materials. When working with small samples, three primary challenges emerge that dictate the choice of equipment.

The Problem of Sample Loss

Large grinders have significant surface area and "dead volume" where material becomes permanently trapped. For a 100-gram sample, losing a gram is a 1% loss; for a 100-milligram sample, it's a catastrophic failure.

Specialized methods use small, often disposable, vials that are self-contained, ensuring that nearly 100% of the starting material is recovered.

The Risk of Cross-Contamination

Residue from a previous sample can easily contaminate the next, invalidating sensitive analytical results. Meticulously cleaning a large, complex mill between each small sample is often impractical and a source of error.

Methods that use single-use grinding vials, like bead mills, virtually eliminate the possibility of cross-contamination between samples.

The Impact of Heat

All grinding generates heat through friction. For many biological samples (like tissues for RNA extraction) or temperature-sensitive polymers, this heat can denature proteins, degrade nucleic acids, or alter the material's fundamental chemical structure.

Techniques like cryogenic grinding directly solve this by making the sample brittle and keeping it inert, while other methods use short, high-energy bursts to minimize heat buildup.

Top Grinding Methods for Small Samples

The right choice depends entirely on your sample type and analytical goal. Here are the most effective methods used in modern laboratory settings.

Bead Mill Homogenizers

Also known as "bead beaters," these instruments use rapid, multi-directional shaking of a sealed tube containing the sample and one or more grinding beads (ceramic, steel, or glass).

This method is the gold standard for homogenizing biological tissues, lysing microbial cells, and extracting nucleic acids or proteins. The process is extremely fast, and the use of disposable tubes makes it ideal for high-throughput applications where contamination control is paramount.

Cryogenic Grinding

Cryogenic milling involves immersing the sample in liquid nitrogen (-196°C or -321°F) before or during the grinding process. This makes otherwise soft, elastic, or tough materials (like plastics, rubber, or fibrous tissue) extremely brittle.

Once embrittled, the sample shatters easily upon impact. This is the only reliable method for grinding materials that would otherwise melt, deform, or degrade from the heat and friction of standard grinding.

Mortar and Pestle

The traditional mortar and pestle remains a viable, if highly manual, option. For simple pulverization of dry, crystalline, or brittle samples, it offers direct tactile control.

However, it is highly operator-dependent, poses a significant risk of sample loss as dust, and requires rigorous cleaning protocols to prevent cross-contamination. High-quality agate or zirconia materials are recommended to prevent contamination from the grinding surfaces themselves.

Understanding the Trade-offs

No single method is perfect for every application. Choosing wisely involves balancing efficiency, cost, and the physical properties of your sample.

Throughput vs. Control

Bead mills are built for throughput, allowing for the simultaneous processing of dozens of samples. A mortar and pestle offers precise manual control over a single sample but is exceptionally low-throughput.

Cost vs. Contamination

The disposable vials and beads for a homogenizer represent a recurring operational cost. In exchange, they offer near-perfect contamination control. A mortar and pestle is a one-time purchase but carries the "cost" of extensive cleaning labor and a higher risk of failed experiments due to contamination.

Sample Type is Non-Negotiable

This is the most critical trade-off. You cannot effectively grind a tough polymer with a mortar and pestle, nor can you use a standard grinder for a temperature-sensitive RNA sample. The physical and chemical nature of your material will always dictate the appropriate technology.

Making the Right Choice for Your Goal

Base your decision on the intended outcome and the nature of your sample.

- If your primary focus is biological cell lysis or DNA/RNA extraction: A bead mill homogenizer is the industry standard for its efficiency, yield, and contamination control.

- If your primary focus is grinding heat-sensitive or elastic materials (e.g., plastics, tough plant tissue): Cryogenic grinding is the only reliable method to achieve a fine powder without degrading the sample.

- If your primary focus is simple pulverization of a brittle, non-hygroscopic material on a minimal budget: A high-quality agate mortar and pestle can be effective, but requires extreme care to ensure data integrity.

By aligning your grinding technique with your sample's unique properties, you ensure the integrity of your results from the very first step.

Summary Table:

| Method | Best For | Key Advantage | Key Consideration |

|---|---|---|---|

| Bead Mill Homogenizer | Biological tissues, cell lysis, high-throughput | Minimal sample loss, no cross-contamination | Recurring cost for disposable vials/beads |

| Cryogenic Mill | Heat-sensitive/elastic materials (plastics, polymers) | Prevents thermal degradation, embrittles tough samples | Requires liquid nitrogen, specialized equipment |

| Mortar and Pestle | Brittle, dry samples on a minimal budget | Direct tactile control, low initial cost | High risk of sample loss and contamination, low throughput |

Struggling with sample loss or degradation in your research?

KINTEK specializes in laboratory grinding equipment and consumables designed specifically for small, precious samples. Our bead mill homogenizers and cryogenic mills ensure maximum yield and sample integrity, providing the reproducibility and contamination control your sensitive analyses demand.

Contact our experts today to find the perfect grinding solution for your specific application and preserve the quality of your work from the very first step.

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the primary function of a ball mill in magnesium production? Optimize Pretreatment for Efficiency

- What is the principle of size reduction in a ball mill? Master Impact & Attrition for Precise Grinding

- Why different sizes of balls are used in ball mill? Optimize Grinding Efficiency and Particle Size Control

- What safety checks should you do before using a grinder? Master the 3-Pillar Inspection for Accident-Free Operation

- What is sample grinding? Achieve Accurate Analysis with Proper Sample Preparation

- What is the primary function of the ball milling process? Optimize Li2MnSiO4/C Precursor Preparation

- What size are the balls in a ball mill? Optimize Your Grinding Process for Peak Efficiency

- What are the operating procedures for a ball mill? Master Speed, Media, and Material for Perfect Grinding