The best technique for determining particle size is the one that is most appropriate for your specific sample and the goals of your analysis. There is no single "best" method; instead, leading techniques like Sieve Analysis, Static Light Scattering (Laser Diffraction), Dynamic Light Scattering, and Image Analysis are each suited for different materials, particle sizes, and analytical questions.

The central challenge is not finding the "best" universal technique, but rather understanding the capabilities and limitations of each method. The right choice depends entirely on matching the instrument's measurement principle to your particle's characteristics and the information you need to obtain.

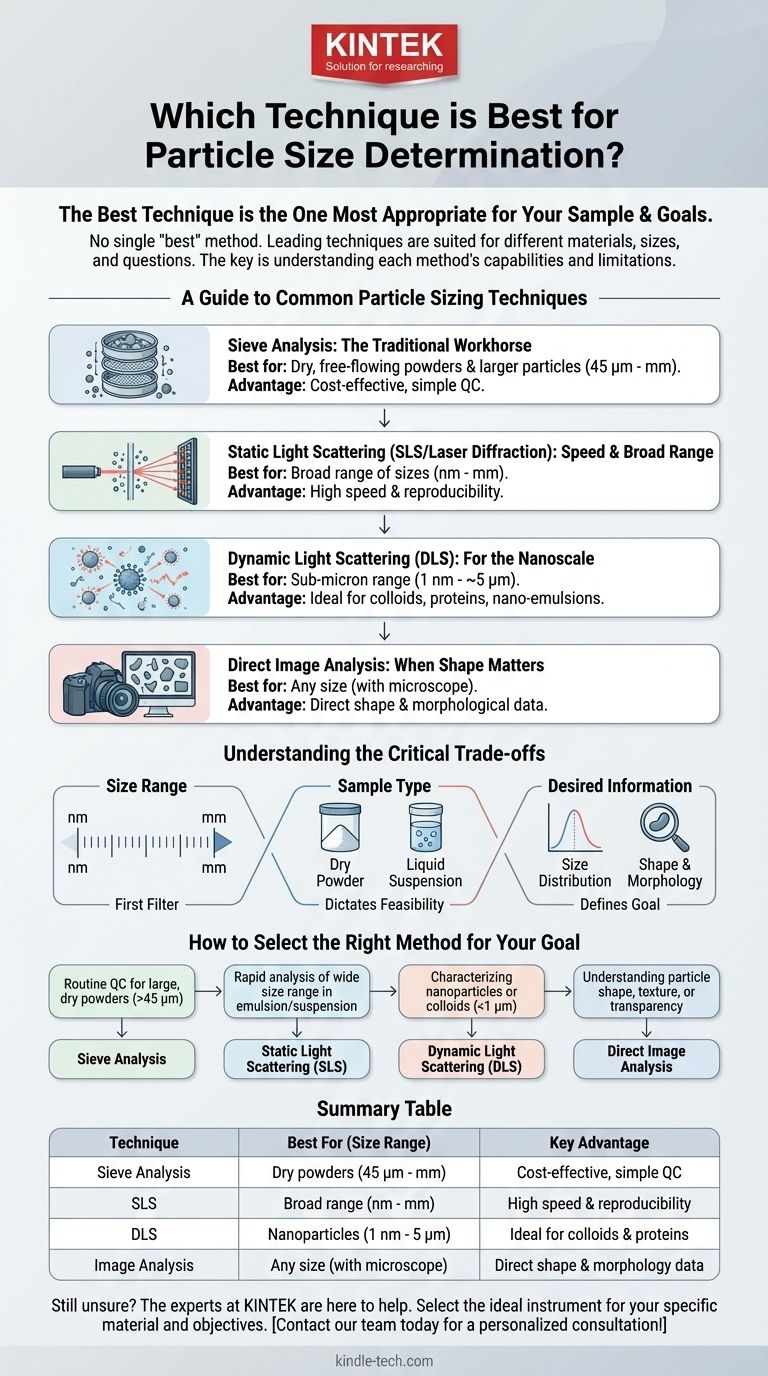

A Guide to Common Particle Sizing Techniques

Choosing a method requires understanding how each one works. The primary techniques operate on fundamentally different principles, making each ideal for a specific range of applications.

Sieve Analysis: The Traditional Workhorse

Sieve analysis is a straightforward, traditional method where a sample is passed through a stack of screens with progressively smaller mesh sizes.

It is best suited for dry, free-flowing powders and larger particles, typically ranging from 45 micrometers to several millimeters. It is cost-effective and easy to perform, making it common in quality control for industries like agriculture, mining, and construction.

Static Light Scattering (SLS): Speed and Broad Range

Also known as Laser Diffraction (LD), this is arguably the most common modern technique. It works by measuring the angular pattern of light scattered by particles as a laser beam passes through a dispersed sample.

SLS is exceptionally versatile, capable of measuring a very broad range of sizes, from hundreds of nanometers to several millimeters. Its speed and high reproducibility make it a powerful tool for research and development across pharmaceuticals, chemicals, and food products.

Dynamic Light Scattering (DLS): For the Nanoscale

DLS measures the fluctuations in scattered light intensity caused by the Brownian motion of particles suspended in a liquid. Smaller particles move more rapidly, allowing the instrument to calculate their size.

This technique is the go-to standard for measuring very small particles, typically in the sub-micron range (1 nanometer to ~5 micrometers). It is essential for characterizing nanoparticles, colloids, proteins, and other nano-emulsions.

Direct Image Analysis: When Shape Matters

This method uses a high-resolution camera and microscope to capture images of individual particles. Sophisticated software then analyzes these images to determine not only size but also shape-related parameters.

Image analysis is unique in its ability to provide detailed morphological data. It is critical when particle shape, not just size, influences product performance, such as with abrasive grains, crystals, or certain pharmaceutical ingredients.

Understanding the Critical Trade-offs

Your choice involves balancing the strengths and weaknesses of each method against your specific requirements. The "best" answer for one project is often the worst for another.

Size Range is the First Filter

Your expected particle size is the most important initial consideration. A method optimized for millimeters (Sieve Analysis) cannot "see" nanoparticles, and a DLS instrument designed for nanoparticles will be overwhelmed by large powders.

Sample Type Dictates Feasibility

Is your sample a dry powder, or is it suspended in a liquid? Sieve analysis is primarily for dry materials, while DLS requires a liquid suspension. SLS and Image Analysis often have options for both wet and dry dispersion, but one may be better suited for your material.

Desired Information Defines the Goal

If you only need a general size distribution curve, SLS is fast and effective. However, if you need to identify a few oversized particles or understand the shape of your particles, only Image Analysis can provide that direct visual information.

How to Select the Right Method for Your Goal

Base your decision on the specific question you are trying to answer.

- If your primary focus is routine QC for large, dry powders (>45 µm): Sieve Analysis offers a simple, reliable, and cost-effective solution.

- If your primary focus is rapid analysis of a wide size range in an emulsion or suspension: Static Light Scattering (Laser Diffraction) is the most versatile and efficient choice.

- If your primary focus is characterizing nanoparticles or colloids below 1 µm: Dynamic Light Scattering is the definitive and most appropriate technology.

- If your primary focus is understanding particle shape, surface texture, or transparency: Direct Image Analysis is the only method that can provide this crucial morphological data.

By matching the technique to your material and your objective, you ensure the generation of accurate and meaningful particle size data.

Summary Table:

| Technique | Best For (Size Range) | Key Advantage |

|---|---|---|

| Sieve Analysis | Dry powders (45 µm - mm) | Cost-effective, simple QC |

| Static Light Scattering (SLS) | Broad range (nm - mm) | High speed & reproducibility |

| Dynamic Light Scattering (DLS) | Nanoparticles (1 nm - 5 µm) | Ideal for colloids & proteins |

| Image Analysis | Any size (with microscope) | Direct shape & morphology data |

Still unsure which particle sizing technique is right for your application?

The experts at KINTEK are here to help. We specialize in lab equipment and consumables, serving all your laboratory needs. We can help you select the ideal instrument to ensure accurate and meaningful particle size data for your specific material and objectives.

Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Single Horizontal Jar Mill

People Also Ask

- What are the precautions of sieve shaker? Ensure Accurate Particle Analysis & Protect Your Equipment

- How does a sieve shaker work? A Guide to Automated Particle Size Analysis

- What are the primary functions of automated crushing and sieving systems in e-waste recycling? Optimize Material Recovery

- What are the hazards of a sieve shaker? Avoid Costly Data Errors in Your Lab

- What is the device used for sieving? Your Guide to Precision Particle Separation

- Why is a laboratory shaker required for continuous 24-hour catalyst treatment? Achieve Deep Uniform Impregnation

- What is the amplitude of a sieve analysis? Master the Key to Accurate Particle Sizing

- What is the function of a constant temperature shaker when washing pretreated wheat straw fibers? Enhance Data Accuracy