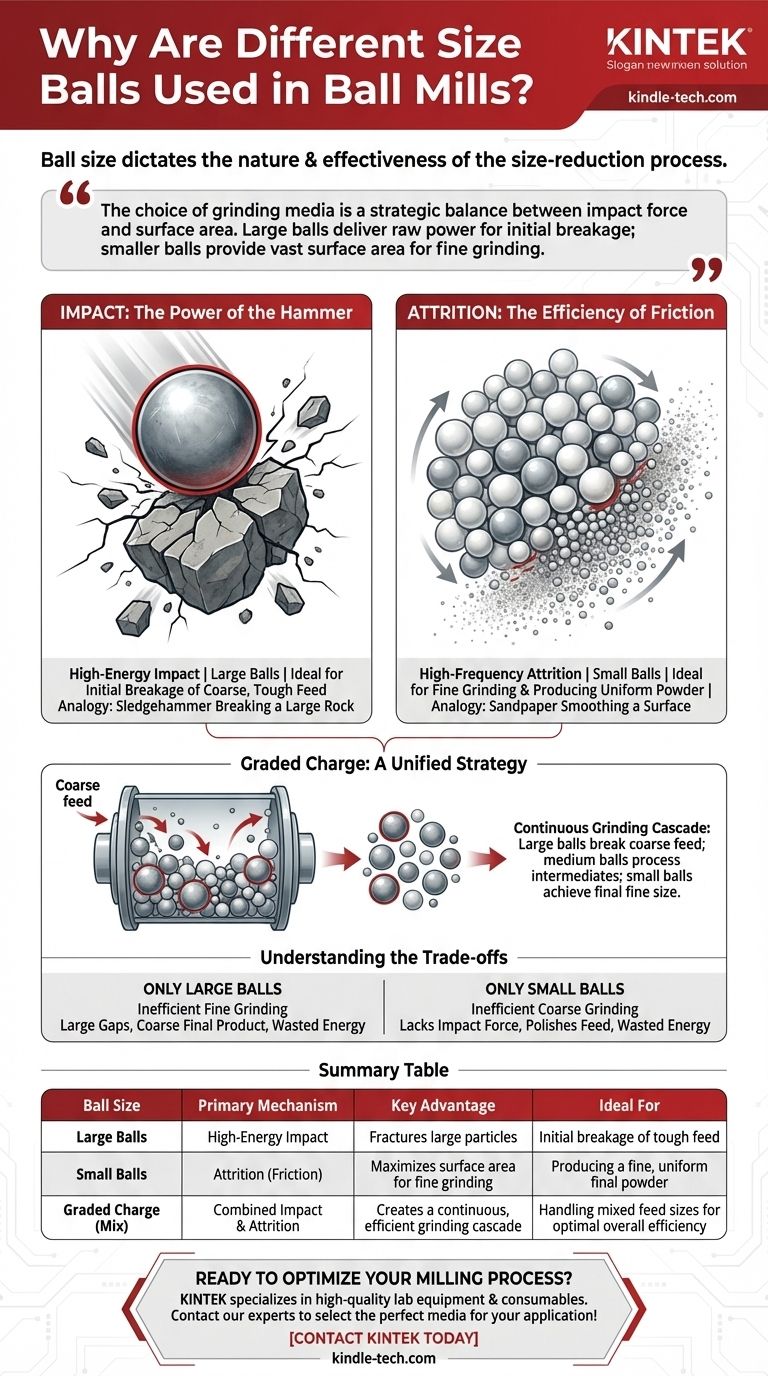

In short, different size balls are used in a ball mill because the size of the grinding ball dictates the nature and effectiveness of the size-reduction process. Large, heavy balls provide the high-energy impact necessary to fracture large, coarse particles, while smaller balls are more efficient at grinding fine particles through attrition. The optimal performance of a mill depends on matching the ball size to the material being processed.

The choice of grinding media is a strategic balance between impact force and surface area. Large balls deliver the raw power needed for initial breakage, whereas a charge of smaller balls provides the vast surface area required for efficient, fine grinding.

The Two Core Grinding Mechanisms

To understand why ball size is so critical, you must first understand the two ways a ball mill reduces material size: impact and attrition. The size of the balls directly influences which of these mechanisms dominates.

Impact: The Power of the Hammer

Impact grinding occurs when a heavy ball, lifted by the rotation of the mill, cascades down and strikes a particle with significant force. This is a high-energy event.

Larger balls, due to their greater mass, generate much higher kinetic energy. This makes them essential for the primary stage of grinding, where you need to apply enough force to create initial fractures in large, tough feed material. Think of it as using a sledgehammer to break a large rock into smaller pieces.

Attrition: The Efficiency of Friction

Attrition is a grinding action that occurs through rubbing and friction as balls and particles slide against one another. This is a lower-energy but higher-frequency event.

For a given weight, a charge of smaller balls has a dramatically larger total surface area than a charge of large balls. This increase in surface area creates significantly more contact points within the mill, maximizing the opportunities for attrition. This mechanism is highly effective for reducing already small particles into a fine powder, similar to using sandpaper to smooth a surface.

How Ball Size Dictates Mill Performance

The right ball charge creates a cascade of grinding efficiency, where particles of every size are being broken down effectively. Using the wrong size leads to wasted energy and poor results.

The Role of Large Balls in Initial Breakage

Large balls are the workhorses of the mill. Their primary function is to accept the coarsest feed and apply enough impact energy to break it down. Without a sufficient number of large balls, the mill would be incapable of processing large material, rendering the entire operation ineffective.

The Advantage of Small Balls for Final Product Size

Small balls are the finishers. By maximizing the attrition effect, they are responsible for achieving a fine final particle size. If your goal is to produce a fine powder, a significant portion of your grinding media must be small balls to provide the necessary surface area for efficient grinding.

The Graded Charge: A Unified Strategy

In most industrial applications, a graded ball charge is used, meaning a mixture of different ball sizes. Large balls break the coarse feed into intermediate sizes. These intermediate particles are then small enough to be effectively ground by the medium-sized balls, which in turn feed even smaller particles to the smallest balls for final attrition. This creates a continuous and efficient grinding process for all particle sizes within the mill.

Understanding the Trade-offs

Selecting a ball charge is not arbitrary; it involves critical trade-offs that directly impact energy consumption and product quality.

The Pitfall of Using Only Large Balls

If a mill is charged only with large balls, it will be effective at breaking coarse feed but highly inefficient at grinding the resulting smaller particles. The large gaps between the balls allow fine material to pass through without being processed, leading to a coarse final product and wasted energy.

The Inefficiency of Using Only Small Balls

Conversely, charging a mill with only small balls to process a coarse feed is a common mistake. The small balls lack the individual mass and impact energy to fracture the large particles. The mill will expend a tremendous amount of energy with very little size reduction, effectively just polishing the surfaces of the feed material.

Making the Right Choice for Your Goal

The ideal ball charge is determined by your feed size, your mill's characteristics, and, most importantly, your desired final product.

- If your primary focus is breaking down large, coarse feed material: Your ball charge must include a significant portion of large-diameter balls to provide the necessary impact energy.

- If your primary focus is achieving a very fine final product: Your charge needs a higher proportion of smaller balls to maximize surface area and promote efficient attrition grinding.

- If your primary focus is maximizing overall efficiency for a mixed feed: Employ a graded charge with a calculated distribution of ball sizes to handle particles at every stage of the reduction process.

Ultimately, mastering the ball charge is the key to controlling the efficiency and final product of any milling operation.

Summary Table:

| Ball Size | Primary Mechanism | Key Advantage | Ideal For |

|---|---|---|---|

| Large Balls | High-Energy Impact | Fractures large, coarse particles | Initial breakage of tough feed material |

| Small Balls | Attrition (Friction) | Maximizes surface area for fine grinding | Producing a fine, uniform final powder |

| Graded Charge (Mix) | Combined Impact & Attrition | Creates a continuous, efficient grinding cascade | Handling mixed feed sizes for optimal overall efficiency |

Ready to optimize your milling process? The right grinding media is critical for achieving your target particle size and maximizing energy efficiency. KINTEK specializes in high-quality lab equipment and consumables, including grinding balls for ball mills. Our experts can help you select the perfect media for your specific material and application. Contact our team today to discuss your grinding needs and enhance your lab's performance!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- What is the particle size for XRD analysis? Optimize Your Results with the Right Preparation

- What is the importance of mixing or grinding diamond and metal powders? Key to High-Performance Composites

- What is the primary technical objective of using mechanical grinding tools? Master Liquid Metal Alloying

- Why is a laboratory ball mill required for Fe-Cr-Mn-Mo-N alloy powders? Unlock High-Performance Alloy Synthesis

- Why is acetone used as a process control agent for YSZ-SiC powders? Achieve Superior Microscopic Dispersion

- What size are grinding balls? Optimize Your Grinding Circuit for Maximum Efficiency

- How does the use of grinding equipment benefit iron-substituted manganese oxide? Optimize Energy Storage Performance

- What is the particle size range of a ball mill? Achieve Precise Grinding from 10 mm to Sub-Micron