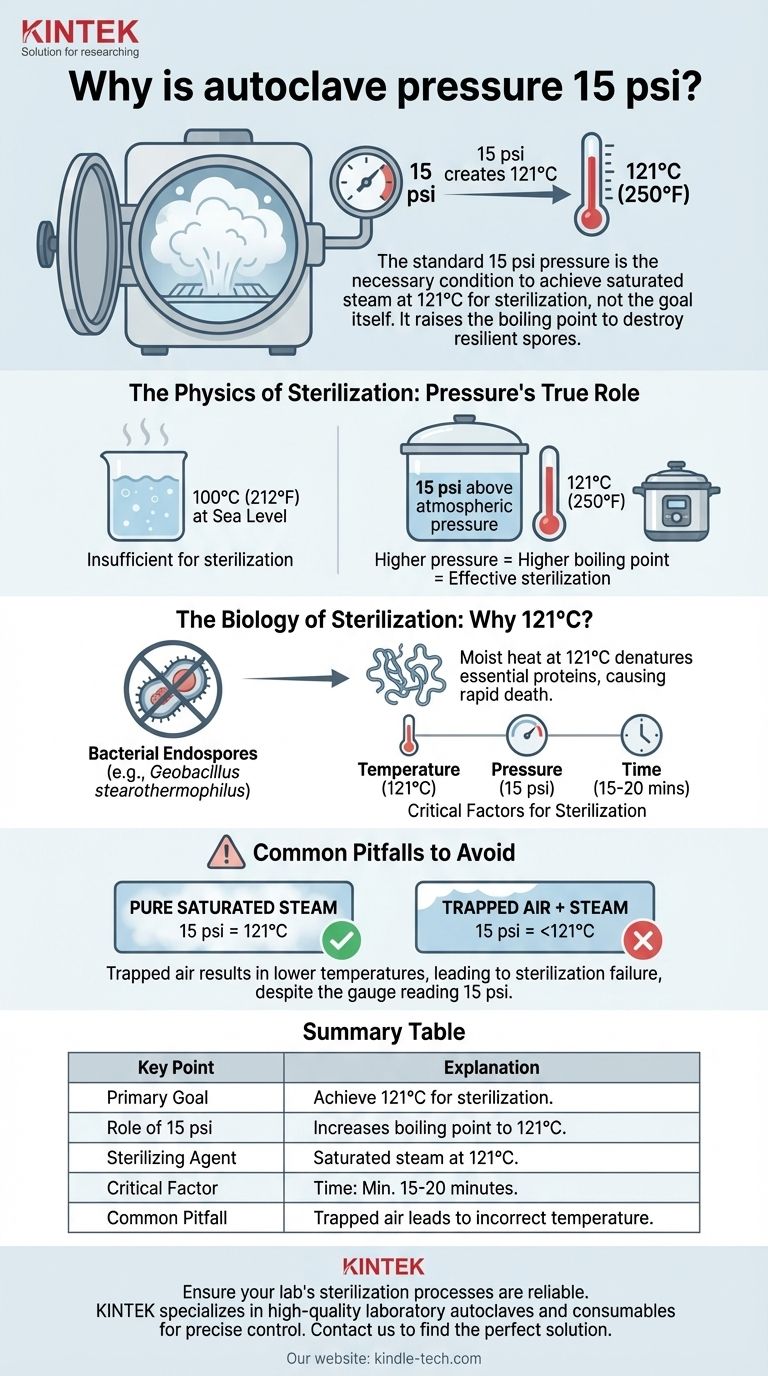

The standard 15 psi pressure in an autoclave is not the goal itself, but rather the necessary condition to achieve the true sterilizing agent: saturated steam at 121°C (250°F). At normal atmospheric pressure, water boils at 100°C, which is not hot enough to reliably kill all microbial life, especially highly resistant bacterial spores. By increasing the pressure inside the sealed chamber, we can elevate the boiling point of water to this much higher, microbicidal temperature.

Autoclaving relies on temperature, not pressure, to kill microbes. Applying 15 pounds per square inch (psi) of pressure is simply the most efficient physical method to raise the boiling point of water to 121°C—the temperature required to denature proteins and destroy even the most resilient bacterial spores.

The Physics of Sterilization: Pressure's True Role

To understand the 15 psi standard, we must first understand the relationship between pressure and temperature. The pressure reading on the gauge is an indicator, but the temperature it produces is what accomplishes the work.

Overcoming the Limits of Boiling Water

At sea level, water boils at 100°C (212°F). While this is hot enough to kill many active bacteria, it is insufficient for sterilization.

The true benchmark for sterilization is the ability to destroy bacterial endospores, which can survive boiling water for extended periods.

The Pressure-Temperature Relationship

When water is heated in a sealed container like an autoclave, the steam cannot escape. This buildup of water vapor increases the pressure inside the chamber.

As pressure increases, the boiling point of water also increases. Think of it like a pressure cooker: the trapped steam raises the pressure, allowing the water and food to reach temperatures well above the normal boiling point, cooking food much faster.

Why 15 psi Hits the Mark

Physics dictates a direct and predictable relationship between the pressure of pure steam and its temperature.

When the pressure inside the autoclave reaches 15 psi above atmospheric pressure, the boiling point of the water inside rises from 100°C to precisely 121°C. This temperature has been scientifically established as the standard for effective sterilization.

The Biology of Sterilization: Why 121°C is the Standard

The entire purpose of an autoclave is to create an environment hostile to all forms of life. The 121°C temperature achieved at 15 psi is the established minimum for this task.

The Target: Bacterial Endospores

The gold standard for sterilization is the destruction of bacterial endospores, such as those from the Geobacillus stearothermophilus species.

These spores are the most heat-resistant life forms known, acting as a biological indicator. If your process can kill them, it is considered successful in killing all other pathogenic organisms.

How Saturated Steam Destroys Spores

Sterilization is achieved through moist heat. At 121°C, saturated steam can rapidly penetrate materials and transfer thermal energy.

This intense heat irreversibly denatures essential proteins and enzymes within the microorganisms, causing their cellular structures to coagulate and leading to rapid death.

Time as a Critical Factor

Temperature and pressure are only two parts of the equation. The third is time.

A standard autoclave cycle runs at 121°C and 15 psi for a minimum of 15 to 20 minutes to ensure the steam has enough time to fully penetrate the load and kill all spores.

Common Pitfalls to Avoid

Focusing only on the pressure gauge is a common and critical mistake that can lead to sterilization failure. The pressure reading does not guarantee that the proper sterilizing conditions have been met.

The Danger of Trapped Air

The 15 psi / 121°C relationship only holds true for pure saturated steam. If air is not properly purged from the autoclave chamber at the beginning of the cycle, the total pressure will be a mix of air and steam.

The gauge might read 15 psi, but the actual steam pressure—and therefore the temperature—will be significantly lower, resulting in an ineffective cycle. This is the single most common reason for sterilization failure.

Pressure is a Means, Not an End

The pressure gauge is a tool to infer temperature, but it is not a direct measurement of sterility. True validation of a sterilization cycle requires the use of chemical indicators, temperature probes, and, most importantly, biological indicators (spore tests).

Making the Right Choice for Your Goal

Understanding the principles behind the numbers allows you to operate equipment effectively and ensure true sterility.

- If your primary focus is routine laboratory sterilization: Trust the standard 15 psi / 121°C for a 15-20 minute cycle, but always ensure the autoclave is loaded correctly to allow for complete air removal and steam penetration.

- If your primary focus is validating a critical process (e.g., medical devices): Rely on biological spore indicators and temperature monitoring data, as the pressure gauge alone does not guarantee sterility.

- If your primary focus is operational safety: Always ensure air is completely purged from the chamber before the cycle begins and never attempt to open the door until the pressure gauge reads zero.

Ultimately, understanding that pressure is the tool and temperature is the weapon empowers you to achieve reliable and verifiable sterilization every time.

Summary Table:

| Key Point | Explanation |

|---|---|

| Primary Goal | Achieve a temperature of 121°C (250°F) for sterilization. |

| Role of 15 psi | Increases the boiling point of water from 100°C to the required 121°C. |

| Sterilizing Agent | Saturated steam at 121°C, which denatures microbial proteins. |

| Critical Factor | Time: A minimum exposure time of 15-20 minutes is required. |

| Common Pitfall | Trapped air can lead to incorrect temperature despite correct pressure reading. |

Ensure your lab's sterilization processes are reliable and effective.

Understanding the science behind autoclave settings is crucial for lab safety and integrity. At KINTEK, we specialize in providing high-quality laboratory autoclaves and consumables designed to deliver precise temperature and pressure control for guaranteed sterility. Our equipment helps you avoid common pitfalls like air entrapment, ensuring your critical processes are validated and your results are trustworthy.

Contact us today to find the perfect autoclave solution for your laboratory's specific needs. Get in touch via our contact form and let our experts help you achieve flawless sterilization.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What are the advantages of using a large-capacity autoclave for the secondary curing of calcium silicate specimens?

- What is the most effective method for sterilization of laboratory materials? Choose the Right Method for Your Lab

- Why must Zircaloy-4 components undergo high-pressure autoclave steam oxidation? Ensure Critical Corrosion Resistance

- What is the primary function and principle of autoclaving? Master Lab Sterilization with High-Pressure Steam

- What are the settings of autoclave in microbiology? Achieve Guaranteed Sterility for Your Lab

- Why is a Teflon-lined autoclave necessary for the hydrothermal treatment of porous TiO2 nanomaterials? Expert Insights

- What should be autoclaved in a lab? A Guide to Safe and Effective Sterilization

- What are the methods of validation of autoclave? Ensure Sterility with a 3-Pillar Approach