At its core, horizontal shaking is more efficient than purely vertical shaking because it performs the crucial job of spreading material across the entire sieve mesh. This action gives each particle the maximum number of opportunities to find and pass through an aperture. In contrast, a simple up-and-down motion often causes particles to bounce in the same spot, leading to inefficient separation and mesh blinding.

The fundamental goal of sieving isn't just to shake a sample, but to achieve two distinct actions: stratification and separation. Horizontal motion is the primary driver of efficient separation, while a vertical component is key for stratification and preventing clogs.

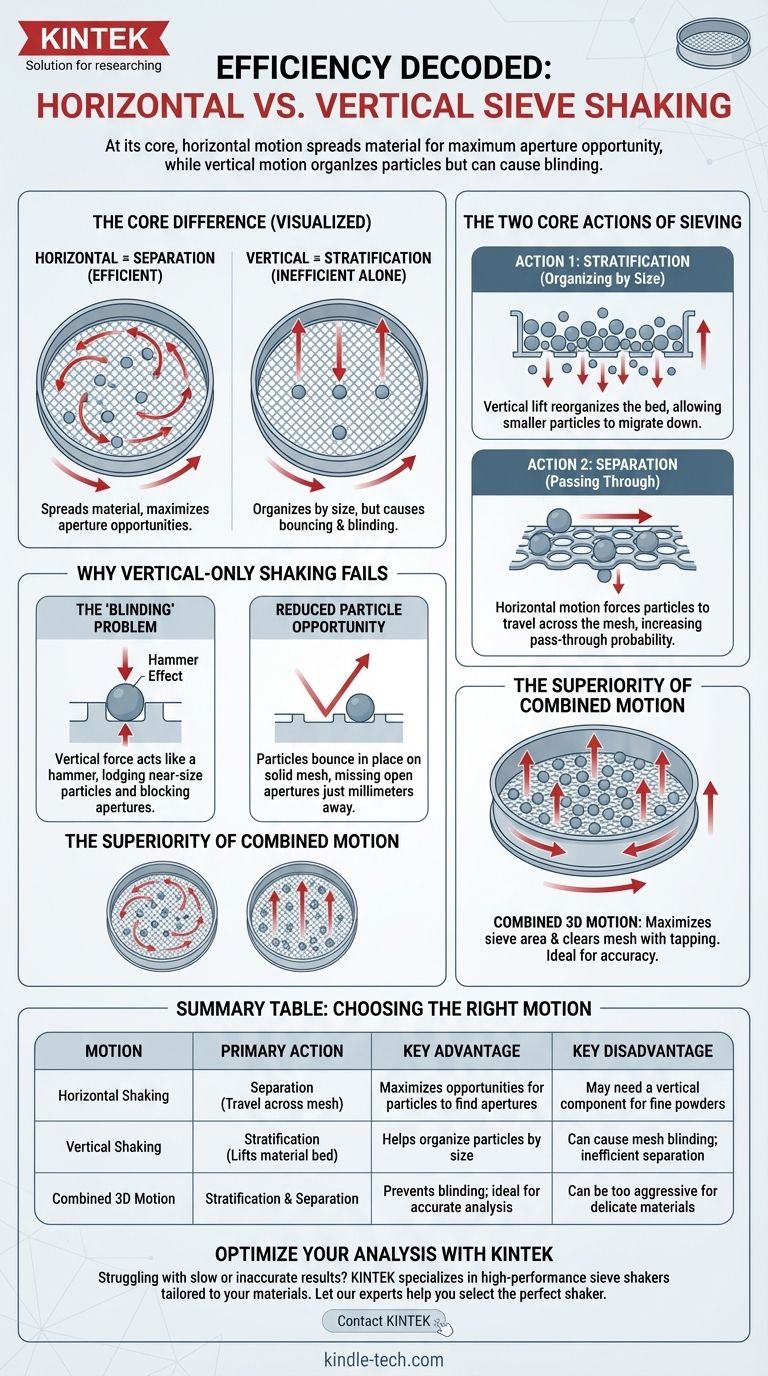

The Two Core Actions of Sieving

To understand efficiency, we must first break down what needs to happen inside the sieve. The process is a two-step mechanical action.

Action 1: Stratification

Stratification is the process of organizing particles by size. As the sieve moves, the entire sample is lifted.

During this brief moment of suspension, smaller particles have the chance to fall through the spaces between larger particles, migrating down toward the sieve mesh.

A vertical component in the shaking motion is essential for this action. It repeatedly lifts the material bed, allowing the size-based reorganization to occur.

Action 2: Separation

Separation is the act of a particle actually passing through a mesh opening. This can only happen after stratification has brought the particle into contact with the mesh.

This is where horizontal motion is the clear winner. A circular or linear horizontal movement forces particles to travel across the mesh surface.

As a particle rolls and tumbles, it "tests" dozens or even hundreds of different apertures, dramatically increasing the probability that it will find one it can fall through.

Why Vertical-Only Shaking is Inefficient

Relying solely on a vertical, up-and-down motion creates several significant problems that reduce both the speed and accuracy of the analysis.

The Problem of "Blinding"

Blinding occurs when a particle that is very close to the size of an aperture becomes lodged in the opening.

A purely vertical motion can act like a hammer, forcing these near-size particles directly into the mesh and causing them to get stuck. This effectively reduces the open area of your sieve, slowing the entire process.

Reduced Particle Opportunity

Without horizontal travel, a particle might land on a solid section of the wire mesh and simply bounce in place.

It has no mechanism to move a few millimeters to the left or right where an open aperture is waiting. This means a significant portion of the sample is not being actively sieved at any given moment.

The Superiority of Combined Motion

The most effective modern sieve shakers do not rely on a single motion. They combine the strengths of both horizontal and vertical movements to create a highly efficient, three-dimensional action.

Maximizing Sieve Area

The horizontal component ensures the sample is distributed evenly across the entire surface of the sieve. This makes full use of the equipment and prevents material from piling up in the center.

The Critical "Tapping" Action

Many advanced shakers incorporate a vertical tap or jarring motion alongside the horizontal rotation.

The horizontal motion handles the separation, while the sharp, intermittent tap serves two purposes: it energizes the particle bed to encourage stratification and, most importantly, it dislodges any particles that may be blinding the mesh.

This combination ensures the sieve remains clear and the separation process is both rapid and complete.

Understanding the Trade-offs

Choosing the right motion isn't just about speed; it's about matching the action to the material to get reliable results.

Particle Characteristics Matter

For very fine, dry powders that tend to agglomerate or hold a static charge, a simple horizontal motion may not be enough. An aggressive vertical tap or even ultrasonic vibration is often necessary to break up clumps and ensure individual particles reach the mesh.

The Risk of Attrition

For friable or delicate materials (those that are easily broken), an aggressive shaking motion with a hard tap can be destructive. The action can shatter the particles, creating more "fines" and skewing the particle size distribution analysis.

Throughput vs. Accuracy

A very fast or aggressive motion might process a sample quickly, but it may not be accurate. Particles need sufficient time—what is known as "residence time"—on the mesh to stratify properly and find an opening. Pushing material through too fast can compromise the quality of the separation.

Making the Right Choice for Your Goal

The ideal sieving motion depends entirely on your material and your objective.

- If your primary focus is rapid screening of free-flowing granules: A strong, purely horizontal circular motion is highly effective and maximizes throughput.

- If your primary focus is high-accuracy analysis of fine or near-size powders: A combined 3D motion (horizontal rotation with a vertical tap) is necessary to prevent blinding and achieve complete separation.

- If your primary focus is processing friable or delicate materials: A gentle horizontal motion without an aggressive tap is required to preserve the integrity of the particles.

Ultimately, understanding how different motions drive stratification and separation empowers you to select the correct tool for an accurate and efficient analysis.

Summary Table:

| Sieving Motion | Primary Action | Key Advantage | Key Disadvantage |

|---|---|---|---|

| Horizontal Shaking | Separation (Particles travel across mesh) | Maximizes opportunities for particles to find apertures | May need a vertical component for fine powders |

| Vertical Shaking | Stratification (Lifts material bed) | Helps organize particles by size | Can cause mesh blinding; inefficient separation |

| Combined 3D Motion | Stratification & Separation | Prevents blinding; ideal for accurate analysis of fine powders | Can be too aggressive for delicate materials |

Struggling with slow sieving or inaccurate results? The right motion is critical for efficient particle size analysis. KINTEK specializes in lab equipment and consumables, serving laboratory needs with a range of high-performance sieve shakers designed for your specific materials—from free-flowing granules to fine, cohesive powders. Let our experts help you select the perfect shaker for maximum accuracy and throughput. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

People Also Ask

- What role does an industrial-grade vibrating sieve play in azide combustion synthesis? Ensure Material Homogeneity

- What is the difference between a shaker and a vortex? Choose the Right Mixer for Your Lab Workflow

- What are the components of a sieving machine? Unlock the Anatomy of Precision Particle Separation

- What role does a reciprocating linear shaker play in formaldehyde extraction? Ensure Accurate Leather Sample Analysis

- What are types of sieve shakers? Choose the Right Agitation for Accurate Particle Analysis

- What is the disadvantage of sieve shaker? Key Limitations in Particle Size Analysis

- What are the disadvantages of sieve shaker method? Uncover the Critical Limitations for Accurate Particle Analysis

- What is the significance of using a fine sieving system for catalyst particles? Optimize Size for Maximum Reactivity