Lab Materials

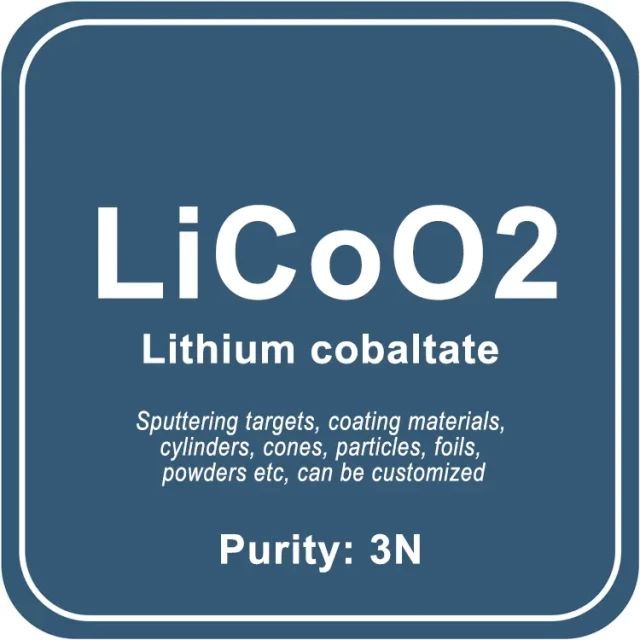

Lithium cobaltate (LiCoO2) Sputtering Target / Powder / Wire / Block / Granule

Item Number : LM-LiCoO2

Price varies based on specs and customizations

- Chemical Formula

- LiCoO2

- Purity

- 3N

- Shape

- discs / wire / block / powder / plates / column targets / step target / custom-made

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

At reasonable prices, we offer Lithium cobaltate (LiCoO2) materials for laboratory use. Our expertise lies in producing and tailoring Lithium cobaltate (LiCoO2) materials of different purities, shapes, and sizes to meet your unique requirements.

We provide a diverse range of specifications and sizes for various products, including sputtering targets (circular, square, tubular, irregular), coating materials, cylinders, cones, particles, foils, powders, 3D printing powders, nanometer powders, wire rods, ingots, and blocks, among others.

Details

About Lithium Cobaltate (LiCoO2)

Lithium cobaltate is a widely used inorganic compound that serves as a positive electrode material for lithium-ion batteries. This compound possesses excellent electrochemical properties that make it a reliable choice for battery applications. Lithium cobaltate appears as a gray-black powder that may cause allergies if inhaled or if it comes in contact with the skin.

Despite its potential health hazards, Lithium cobaltate remains a popular choice for battery manufacturers due to its high energy density and stable cycling performance. Ongoing research continues to explore ways to mitigate its harmful effects and make it a safer option for use in various applications.

Ingredient Quality Control

- Raw material composition analysis

- Through the use of equipment such as ICP and GDMS, the content of metal impurities is detected and analyzed to ensure that it meets the purity standard;

Non-metallic impurities are detected by equipment such as carbon and sulfur analyzers, nitrogen and oxygen analyzers. - Metallographic flaw detection analysis

- The target material is inspected using flaw detection equipment to ensure that there are no defects or shrinkage holes inside the product;

Through metallographic testing, the internal grain structure of the target material is analyzed to ensure that the grains are fine and dense. - Appearance and dimension inspection

- Product dimensions are measured using micrometers and precision calipers to ensure compliance with drawings;

The surface finish and cleanliness of the product are measured using a surface cleanliness meter.

Conventional Sputtering Target Sizes

- Preparation process

- hot isostatic pressing, vacuum melting, etc.

- Sputtering target shape

- plane sputtering target, multi-arc sputtering target, step sputtering target, special-shaped sputtering target

- Round sputtering target size

- Diameter: 25.4mm / 50mm / 50.8mm / 60mm / 76.2mm / 80mm / 100mm / 101.6mm / 152.4mm

Thickness: 3mm / 4mm / 5mm / 6mm / 6.35mm

Size can be customized. - Square sputtering target size

- 50×50×3mm / 100×100×4mm / 300×300×5mm, size can be customized

Available Metal Forms

Metal Forms Details

We manufacture almost all the metals listed on the periodic table in a wide range of forms and purities, as well as standard sizes and dimensions. We can also produce custom-made products to meet specific customer requirements, such as size, shape, surface area, composition, and more. The following list provides a sample of the forms we offer, but it is not exhaustive. If you need laboratory consumables, please contact us directly to request a quote.

- Flat/Planar Forms: Board, Film, Foil, Microfoil, Microleaf, Paper, Plate, Ribbon, Sheet, Strip, Tape, Wafer

- Preformed Shapes: Anodes, Balls, Bands, Bars, Boats, Bolts, Briquettes, Cathodes, Circles, Coils, Crucibles, Crystals, Cubes, Cups, Cylinders, Discs, Electrodes, Fibers, Filaments, Flanges, Grids, Lenses, Mandrels, Nuts, Parts, Prisms, Pucks, Rings, Rods, Shapes, Shields, Sleeves, Springs, Squares, Sputtering Targets, Sticks, Tubes, Washers, Windows, Wires

- Microsizes: Beads, Bits, Capsules, Chips, Coins, Dust, Flakes, Grains, Granules, Micropowder, Needles, Particles, Pebbles, Pellets, Pins, Pills, Powder, Shavings, Shot, Slugs, Spheres, Tablets

- Macrosizes: Billets, Chunks, Cuttings, Fragments, Ingots, Lumps, Nuggets, Pieces, Punchings, Rocks, Scraps, Segments, Turnings

- Porous and Semi-Porous: Fabric, Foam, Gauze, Honeycomb, Mesh, Sponge, Wool

- Nanoscale: Nanoparticles, Nanopowders, Nanofoils, Nanotubes, Nanorods, Nanoprisms

- Others: Concentrate, Ink, Paste, Precipitate, Residue, Samples, Specimens

KinTek specializes in the manufacturing of high-purity and ultra-high-purity materials with a purity range of 99.999% (5N), 99.9999% (6N), 99.99995% (6N5), and in some cases, up to 99.99999% (7N). Our materials are available in specific grades, including UP/UHP, semiconductor, electronic, deposition, fiber optic, and MBE grades. Our high-purity metals, oxides, and compounds are specifically crafted to meet the rigorous demands of high-technology applications and are ideal for use as dopants and precursor materials for thin film deposition, crystal growth of semiconductors, and synthesis of nanomaterials. These materials find use in advanced microelectronics, solar cells, fuel cells, optical materials, and other cutting-edge applications.

Packaging

We use vacuum packaging for our high-purity materials, and each material has specific packaging tailored to its unique characteristics. For instance, our Hf sputter target is externally tagged and labeled to facilitate efficient identification and quality control. We take great care to prevent any damage that could occur during storage or transportation.

FAQ

What are the main types of battery materials?

What are the applications of battery materials?

What are the materials used in electrochemical cell?

How do battery materials enhance battery performance?

What are the examples of electrochemical material?

What is the role of polyethylene separators in lithium-ion batteries?

Why are conductive carbon cloths/papers/felts important in battery applications?

What are the advantages of using aluminum-plastic flexible packaging films for lithium batteries?

How does the lithium cobaltate material contribute to battery performance?

What is the function of battery internal resistance testers?

Why are nickel-aluminum tabs important in battery manufacturing?

4.8

out of

5

The quality of the Lithium cobaltate (LiCoO2) Sputtering Target is outstanding. It has met all our expectations and has been a valuable addition to our laboratory.

4.9

out of

5

KINTEK SOLUTION's Lithium cobaltate (LiCoO2) Sputtering Target is a lifesaver! It has significantly improved our research efficiency and accuracy. Thank you, KINTEK SOLUTION!

4.7

out of

5

The Lithium cobaltate (LiCoO2) Sputtering Target from KINTEK SOLUTION is a game-changer for our laboratory. It's reliable, durable, and has helped us achieve remarkable results. Highly recommended!

5.0

out of

5

KINTEK SOLUTION's Lithium cobaltate (LiCoO2) Sputtering Target is a testament to their commitment to quality. It's an exceptional product that has exceeded our expectations. Thank you for your dedication!

4.6

out of

5

The Lithium cobaltate (LiCoO2) Sputtering Target from KINTEK SOLUTION has been a valuable asset to our research. It's a reliable and efficient product that has helped us make significant progress. Keep up the great work!

4.8

out of

5

KINTEK SOLUTION's Lithium cobaltate (LiCoO2) Sputtering Target is top-notch. The quality is impeccable, and it has made our research work so much easier. Highly satisfied!

4.9

out of

5

As a laboratory manager, I highly recommend KINTEK SOLUTION's Lithium cobaltate (LiCoO2) Sputtering Target. It's a high-performing product that has enhanced our research capabilities. Thank you, KINTEK SOLUTION!

5.0

out of

5

The Lithium cobaltate (LiCoO2) Sputtering Target from KINTEK SOLUTION is simply outstanding. It has revolutionized our research and enabled us to achieve remarkable breakthroughs. Thank you for this incredible product!

4.7

out of

5

KINTEK SOLUTION's Lithium cobaltate (LiCoO2) Sputtering Target is a testament to their expertise and dedication to quality. It's a reliable and efficient product that has made our research work more productive. Thank you!

4.9

out of

5

The Lithium cobaltate (LiCoO2) Sputtering Target from KINTEK SOLUTION is a true game-changer. It has significantly improved the accuracy and efficiency of our research. Highly recommended!

4.8

out of

5

KINTEK SOLUTION's Lithium cobaltate (LiCoO2) Sputtering Target is a remarkable product. It has exceeded our expectations and has been instrumental in our research breakthroughs. Thank you for your commitment to excellence!

5.0

out of

5

The Lithium cobaltate (LiCoO2) Sputtering Target from KINTEK SOLUTION is a masterpiece of engineering. It's a high-quality product that has transformed our research capabilities. Highly recommended!

4.7

out of

5

KINTEK SOLUTION's Lithium cobaltate (LiCoO2) Sputtering Target is a valuable addition to our laboratory. It's a durable and reliable product that has enhanced our research outcomes. Thank you!

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

High Purity Cobalt (Co) Sputtering Target / Powder / Wire / Block / Granule

Get affordable Cobalt (Co) materials for laboratory use, tailored to your unique needs. Our range includes sputtering targets, powders, foils, and more. Contact us today for customized solutions!

Lithium Titanate (Li2TiO3) Sputtering Target / Powder / Wire / Block / Granule

Get high-quality Lithium Titanate materials for your lab needs at affordable prices. We offer tailored solutions with different shapes, sizes, and purities. Find sputtering targets, powders, and more in various specifications.

Lithium Tantalate (LiTaO3) Sputtering Target / Powder / Wire / Block / Granule

Find affordable Lithium Tantalate materials for laboratory use at our company. We specialize in producing tailored shapes and sizes to suit your unique needs, including sputtering targets, coating materials, and more.

Iithium titanate (LiTiO3) Sputtering Target / Powder / Wire / Block / Granule

Get high-quality Iithium Titanate (LiTiO3) materials for your laboratory at reasonable prices. Our tailored solutions cater to different purities, shapes, and sizes, including sputtering targets, coating materials, powders, and more. Order now!

Lithium Aluminum Alloy (AlLi) Sputtering Target / Powder / Wire / Block / Granule

Looking for Lithium Aluminum Alloy materials for your lab? Our expertly produced and tailored AlLi materials come in various purities, shapes, and sizes, including sputtering targets, coatings, powders, and more. Get reasonable prices and unique solutions today.

Cobalt Silicide (CoSi2) Sputtering Target / Powder / Wire / Block / Granule

Looking for affordable Cobalt Silicide materials for your laboratory research? We offer tailored solutions of different purities, shapes, and sizes, including sputtering targets, coating materials, and more. Explore our range now!

Polyethylene separator for lithium battery

The polyethylene separator is a key component of lithium-ion batteries, located between the positive and negative electrodes. They allow the passage of lithium ions while inhibiting electron transport. The performance of the separator affects the capacity, cycle and safety of the battery.

Manganese Cobalt Nickel alloy (MnCoNi) Sputtering Target / Powder / Wire / Block / Granule

Get top-quality Manganese Cobalt Nickel alloy materials for your laboratory needs at affordable prices. Our customized products come in various sizes and shapes, including sputtering targets, coating materials, powders, and more.

Cobalt Telluride (CoTe) Sputtering Target / Powder / Wire / Block / Granule

Get high-quality Cobalt Telluride materials for your laboratory needs at reasonable prices. We offer customized shapes, sizes, and purities, including sputtering targets, coatings, powders, and more.

High Purity Chromium Oxide (Cr2O3) Sputtering Target / Powder / Wire / Block / Granule

Looking for high-quality Chromium Oxide materials for your lab? Our range includes sputtering targets, powders, foils, and more, customized to your needs. Shop now for reasonable prices.

Cylindrical battery steel case

Lithium-ion battery casing suppresses battery polarization, reduces thermal effects, and improves rate performance.

High Purity Lead (Pb) Sputtering Target / Powder / Wire / Block / Granule

Looking for high-quality Lead (Pb) materials for your laboratory needs? Look no further than our specialized selection of customizable options, including sputtering targets, coating materials, and more. Contact us today for competitive pricing!

Aluminum foil current collector for lithium battery

The surface of aluminum foil is extremely clean and hygienic, and no bacteria or microorganisms can grow on it. It is a non-toxic, tasteless and plastic packaging material.

Lithium air battery (lithium oxygen battery) dedicated battery box. The positive electrode is punched from the inside out, and the inside is smooth.

Nickel-aluminum tabs for soft pack lithium batteries

Nickel tabs are used to manufacture cylindrical and pouch batteries, and positive aluminum and negative nickel are used to produce lithium-ion and nickel batteries.

Aluminum-plastic flexible packaging film for lithium battery packaging

Aluminum-plastic film has excellent electrolyte properties and is an important safe material for soft-pack lithium batteries. Unlike metal case batteries, pouch batteries wrapped in this film are safer.

Related Articles

Carbon Coating for Surface Modification of Silicon-Based Materials in Lithium-Ion Batteries

This article discusses the application of carbon coatings to improve the performance of silicon-based anode materials in lithium-ion batteries.

Technical Overview of Silicon-Carbon Anode Materials Prepared by CVD Method

This article discusses the key technical aspects of silicon-carbon anode materials prepared via CVD, focusing on their synthesis, performance improvements, and industrial application potential.