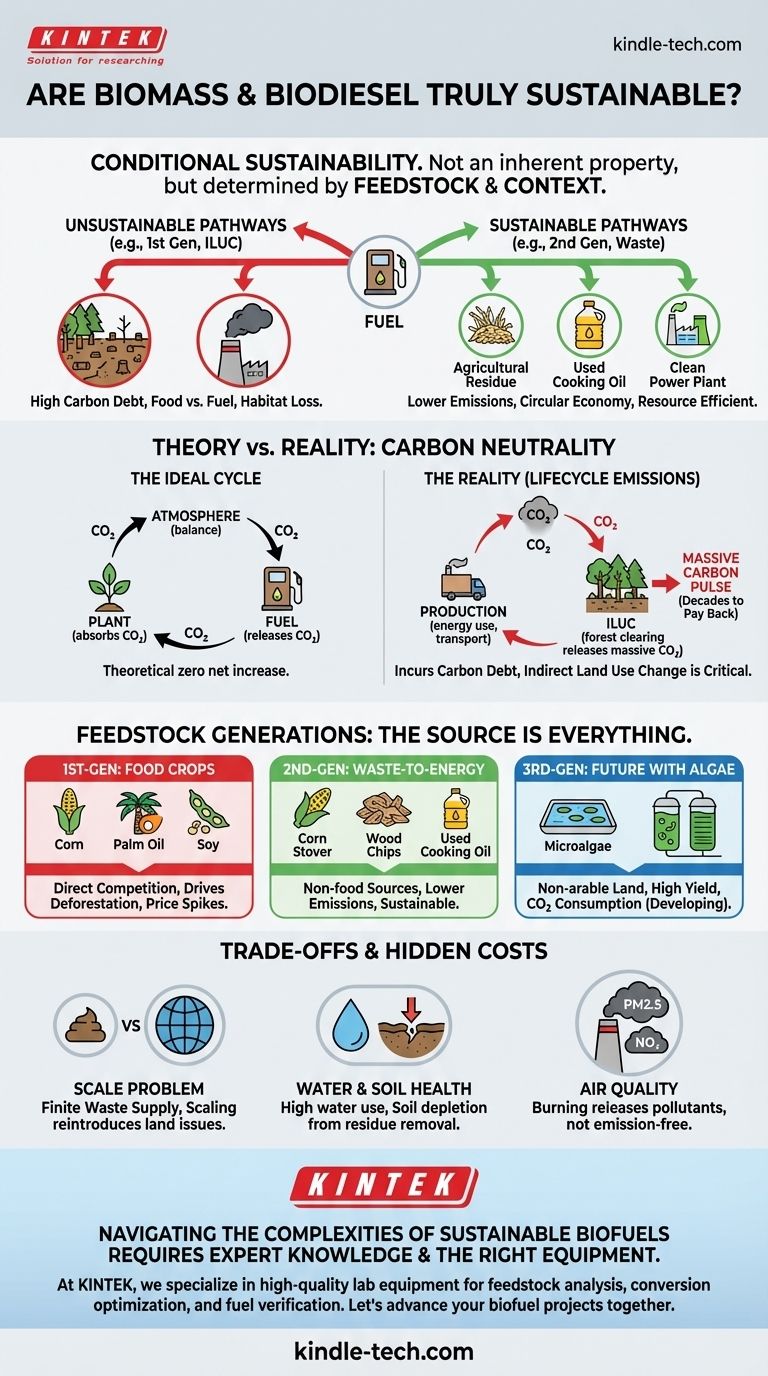

The direct answer is that their sustainability is conditional. While biomass and biodiesel are often presented as simple "green" alternatives, their true environmental credentials are not guaranteed. The sustainability of these fuels depends entirely on their specific source, the methods used for their production, and the context of their use. Some forms can offer significant environmental benefits, while others may be more damaging than the fossil fuels they intend to replace.

True sustainability in biomass and biodiesel is not an inherent property of the fuel itself, but is determined entirely by its feedstock. The critical distinction lies between using genuine waste streams, which is largely beneficial, and displacing food crops or natural ecosystems, which often negates any climate advantage.

The Theory of Carbon Neutrality vs. The Reality

At the heart of the debate is the concept of carbon neutrality. The theory is simple and appealing, but the real-world application is far more complex.

The Ideal Carbon Cycle

The core argument for biomass is that it's part of a closed carbon loop. A plant absorbs atmospheric CO2 as it grows. When that plant material is burned or converted to fuel, it releases the same amount of CO2 back into the atmosphere. In this ideal scenario, there is no net increase in atmospheric carbon.

The Reality of Lifecycle Emissions

This simple loop ignores the "carbon debt" incurred during production. Energy, often from fossil fuels, is required to plant, fertilize, harvest, process, and transport the biomass or its feedstock. These emissions must be accounted for in any honest carbon assessment.

The Critical Flaw: Indirect Land Use Change (ILUC)

This is the single most important factor undermining sustainability. When forests, wetlands, or grasslands are cleared to grow energy crops like palm, soy, or corn, massive amounts of carbon stored in the soil and existing vegetation are released. This initial carbon pulse can be so large that it takes decades, or even centuries, of biofuel production to "pay back" the debt, making it a poor solution for near-term climate goals.

Deconstructing the Feedstocks: The Source is Everything

Not all biomass or biodiesel is created equal. The source material, or feedstock, is the primary determinant of its sustainability. We can group these into generations.

First-Generation: The "Food vs. Fuel" Dilemma

These fuels are derived directly from food crops. This includes ethanol from corn and sugar cane, and biodiesel from soy, canola, and palm oil. This approach creates direct competition for agricultural land and water resources, which can drive up food prices and threaten food security. Using palm oil is particularly destructive, as it is a primary driver of deforestation in tropical rainforests.

Second-Generation: The Waste-to-Energy Model

This generation uses non-food sources, primarily agricultural residues, forestry waste, and other waste products. Examples include corn stover (the stalks and leaves), wood chips from sustainably managed forests, and used cooking oil. Because these feedstocks do not require dedicated land and repurpose a waste stream, their lifecycle emissions are dramatically lower and they are considered far more sustainable.

Third-Generation: The Future with Algae

This emerging category focuses on feedstocks like microalgae. Algae can be cultivated in ponds on non-arable land or even in bioreactors, avoiding competition with food crops entirely. They have a very high yield and can consume CO2 from industrial sources, making them a highly promising, though not yet commercially mature, pathway for sustainable biofuel.

Understanding the Trade-offs and Hidden Costs

Even with the best intentions, implementing biofuel solutions at scale presents significant challenges that must be considered.

The Problem of Scale

While utilizing waste streams is beneficial, the supply of genuine, sustainably sourced waste is finite. There is simply not enough agricultural residue or used cooking oil available globally to make a major dent in our fossil fuel consumption. Scaling up requires moving back toward dedicated crops, reintroducing the problems of land use.

Water Consumption and Soil Health

Growing any crop at an industrial scale requires significant water resources. In water-scarce regions, irrigating energy crops can strain local supplies. Furthermore, repeatedly harvesting agricultural residue can deplete soil organic matter over time, reducing fertility and requiring more fertilizer inputs.

Air Quality Concerns

Burning solid biomass, especially in older or less advanced facilities, can release particulate matter (PM2.5), nitrogen oxides (NOx), and other pollutants that are harmful to human health. While often cleaner than coal in terms of sulfur, biomass combustion is not emission-free.

Making an Informed Assessment

When evaluating a biomass or biodiesel project, your assessment must hinge on its specific context. The right questions are more important than a generic label.

- If your primary focus is immediate climate impact: Prioritize fuels made from verified waste streams (used cooking oil, agricultural residue) or those that demonstrably do not cause land-use change.

- If your primary focus is energy independence: Recognize that while biofuels can contribute, their scalability is limited by sustainable feedstock availability and they should be part of a diverse energy portfolio, not a single solution.

- If your primary focus is holistic sustainability: Look beyond carbon and evaluate the full lifecycle, including the project's impact on local water resources, biodiversity, food prices, and air quality.

Treating biomass and biodiesel as a universally "green" solution is a mistake; the key is to champion the specific pathways that solve problems without creating new ones.

Summary Table:

| Sustainability Factor | Key Consideration |

|---|---|

| Carbon Neutrality | Theoretical vs. real-world emissions; includes production carbon debt and ILUC. |

| Feedstock Generation | 1st-gen (food crops) vs. 2nd-gen (waste) vs. 3rd-gen (algae). |

| Land Use Change (ILUC) | Critical flaw: clearing natural ecosystems creates massive carbon debt. |

| Scalability | Limited by sustainable waste stream availability; scaling reintroduces land-use issues. |

| Environmental Trade-offs | Impacts on water resources, soil health, and air quality (particulate matter). |

Navigating the complexities of sustainable biofuels requires expert knowledge and the right equipment. At KINTEK, we specialize in providing high-quality lab equipment and consumables essential for biofuel research, development, and quality control. Whether you're analyzing feedstock, optimizing conversion processes, or verifying fuel properties, our solutions help you make informed, sustainable choices. Let's advance your biofuel projects together—contact our experts today to discuss your specific laboratory needs.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Ultra-Vacuum Electrode Feedthrough Connector Flange Power Electrode Lead for High-Precision Applications

People Also Ask

- What is the principle of magnetron sputtering technique? Achieve Superior Thin-Film Deposition

- What thickness is magnetron sputtering for coating? Achieve Precise, Functional Thin Films

- What is the thermal debinding process? A Guide to Safe Binder Removal for MIM & Ceramics

- Why must a forced air drying oven be used for fluorosilicone rubber post-curing? Ensure Peak Material Performance

- What is an example of a sintered material? Discover High-Performance Tungsten Carbide & Ceramics

- How to start a lab grown diamond business? Choose the Right Model for Success

- What is the process of making bio-oil? Convert Biomass to Liquid Fuel via Pyrolysis

- What is the unit of thickness of thin film? Mastering Nanometer, Micrometer, and Angstrom Scales