Under typical laboratory conditions, a tube furnace equipped with a standard quartz tube is designed to operate under either a vacuum or a very low positive pressure. This pressure must not exceed 0.2 bars, which is equivalent to 3 psi or 0.02 MPa. Pushing beyond this strict, low-pressure limit risks the structural failure of the process tube, especially at elevated temperatures.

A tube furnace is fundamentally a controlled-atmosphere device, not a high-pressure reactor. Its operational limits are dictated by the material properties of the process tube, which is highly susceptible to both pressure differentials and thermal shock.

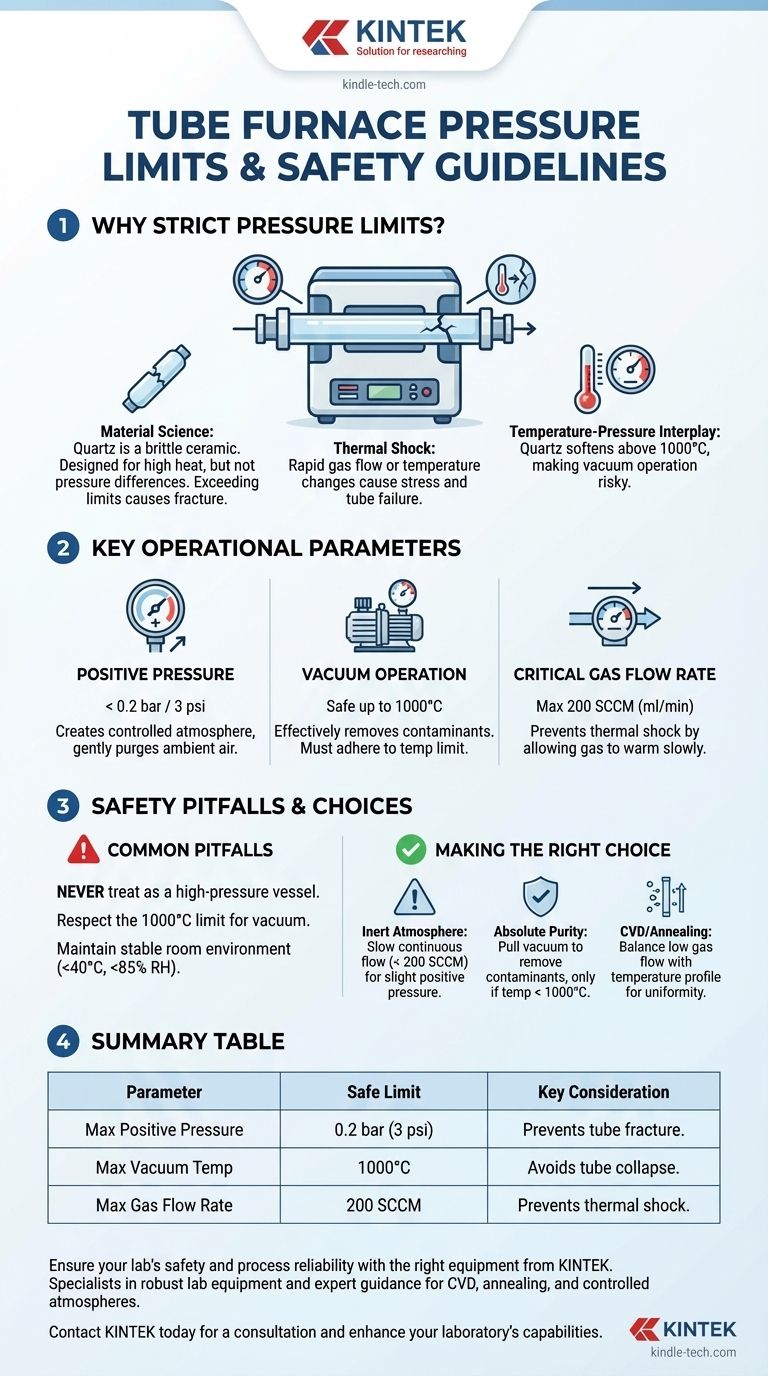

Why Tube Furnaces Have Strict Pressure Limits

Understanding the "why" behind these pressure constraints is critical for both safety and experimental success. The limitations are not arbitrary; they are based on the physical properties of the materials involved, primarily the quartz tube at the heart of the system.

The Material Science of Quartz Tubes

The process tube, most commonly made of quartz, is chosen for its excellent thermal stability and chemical resistance. However, it is a brittle ceramic material.

While it can withstand extreme heat, it is not engineered to handle significant pressure differences between its interior and the outside atmosphere. Exceeding the 0.2 bar limit can cause the tube to fracture.

The Danger of Thermal Shock

Rapid temperature changes create stress within the quartz material, a phenomenon known as thermal shock. This is a primary cause of tube failure.

A high flow rate of a cool process gas into a hot furnace tube is a common trigger for thermal shock. This is why gas flow must be carefully controlled.

The Interplay of Temperature and Pressure

The structural integrity of any material degrades at high temperatures. Quartz is no exception.

For this reason, operating under a vacuum is only considered safe up to 1000°C. Above this temperature, the material softens, making it more vulnerable to collapsing under external atmospheric pressure.

Key Operational Parameters

To ensure safe and effective use, you must operate within three distinct parameters: positive pressure, vacuum, and gas flow rate.

Positive Pressure Operation

A slight positive pressure (less than 0.2 bar / 3 psi) is used to create a specific, controlled atmosphere. This is typically done by flowing an inert or reactant gas through the tube.

The primary goal is to gently purge the ambient air and prevent its re-entry, ensuring the purity of your experimental environment.

Vacuum Operation

Applying a vacuum is the most effective way to remove atmospheric gases and other volatile contaminants before heating or introducing a specific process gas.

This ensures a clean starting point for sensitive reactions. However, it must be done with strict adherence to the 1000°C temperature limit.

Critical Gas Flow Rate

To prevent the dangerous effects of thermal shock, the flow rate of any gas introduced into the tube must be limited.

A maximum flow rate of 200 SCCM (Standard Cubic Centimeters per Minute), or 200 ml/min, is recommended. This slow, controlled introduction allows the gas to warm before reaching the hottest part of the tube, minimizing stress on the quartz.

Common Pitfalls and Safety Considerations

Mistakes in operating a tube furnace often stem from misunderstanding its core design principles. Avoiding these pitfalls is essential for laboratory safety.

Never Treat It as a Pressure Vessel

The single most critical safety rule is to never attempt to use a standard tube furnace for high-pressure experiments. It is not designed or built for this purpose, and doing so creates a significant risk of explosive failure.

Respect the Temperature-Vacuum Link

Do not assume you can operate under vacuum at the furnace's maximum temperature. Always cross-reference your target temperature with the 1000°C safety limit for vacuum conditions.

Maintain a Stable Environment

The furnace itself should be operated in a controlled environment. For optimal performance and equipment longevity, the ambient room temperature should be below 40°C with a relative humidity of less than 85%.

Making the Right Choice for Your Goal

Your experimental objective will determine the correct operational parameters for the furnace.

- If your primary focus is creating an inert or specific gas atmosphere: Use a slow, continuous gas flow (< 200 SCCM) to maintain a slight positive pressure (< 0.2 bar).

- If your primary focus is ensuring absolute purity before a reaction: Begin by pulling a vacuum to remove all atmospheric contaminants, but only if your process temperature will remain below 1000°C.

- If your primary focus is a chemical vapor deposition (CVD) or annealing process: You must carefully balance a low gas flow rate with the required temperature profile to achieve uniformity without causing thermal shock.

Adhering to these pressure and flow boundaries is fundamental to achieving reliable results and ensuring the long-term integrity of your equipment.

Summary Table:

| Parameter | Safe Limit | Key Consideration |

|---|---|---|

| Maximum Positive Pressure | 0.2 bar (3 psi, 0.02 MPa) | Prevents quartz tube fracture. |

| Maximum Vacuum Temperature | 1000°C | Avoids tube collapse at high heat. |

| Maximum Gas Flow Rate | 200 SCCM (200 ml/min) | Prevents thermal shock. |

Ensure your lab's safety and process reliability with the right equipment from KINTEK.

Operating a tube furnace beyond its strict pressure limits risks dangerous equipment failure and compromised results. KINTEK specializes in providing robust lab equipment and expert guidance for your specific thermal processing needs, whether for CVD, annealing, or creating controlled atmospheres.

Let our experts help you select the perfect furnace and consumables to achieve precise, safe, and repeatable outcomes.

Contact KINTEK today for a consultation and enhance your laboratory's capabilities.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What factors influence the general design of a tube furnace? Match Your Process with the Perfect System

- How do you clean a tube furnace tube? A Step-by-Step Guide to Safe and Effective Cleaning

- Why is a high-purity alumina lining required for high-temperature tube furnaces? Ensure Accurate Biomass Research

- What are the advantages of using an alumina liner in a tube furnace for biomass combustion corrosion simulations?

- What tube is used for tubular furnace? Choose the Right Material for Temperature & Atmosphere