To clean a tube furnace tube, you must first ensure the furnace is completely cool and powered off. The specific cleaning method then depends entirely on the tube material (e.g., quartz, alumina) and the type of contaminant, ranging from a simple high-temperature bake-out for organic residue to careful chemical washing for inorganic films.

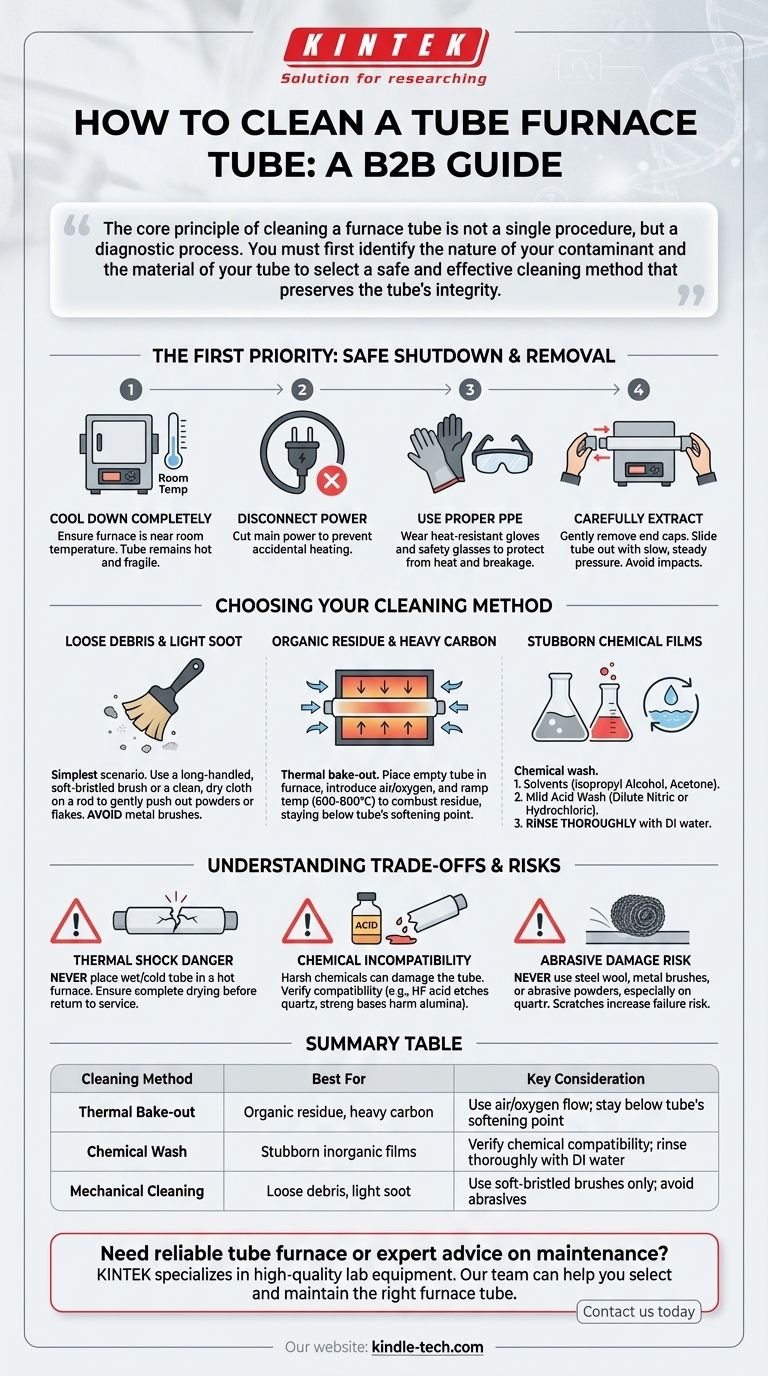

The core principle of cleaning a furnace tube is not a single procedure, but a diagnostic process. You must first identify the nature of your contaminant and the material of your tube to select a safe and effective cleaning method that preserves the tube's integrity for future use.

The First Priority: Safe Shutdown and Removal

Before any cleaning can begin, the system must be brought to a safe, inert state. Rushing this process is the most common source of equipment damage or personal injury.

Step 1: Ensure a Complete Cooldown

The furnace must be at or near room temperature before you handle the tube. While gas and water can often be shut off below 200℃, the tube itself remains extremely hot and susceptible to thermal shock if contacted by cooler liquids or tools.

Step 2: Disconnect from Power

Completely cut off the main power supply to the furnace controller. This prevents any possibility of accidental heating during the removal or cleaning process.

Step 3: Use Proper Personal Protective Equipment (PPE)

Always wear heat-resistant gloves and safety glasses. Even a cooled furnace can have hot spots, and the tube itself can be fragile. Proper PPE protects you from both heat and potential breakage.

Step 4: Carefully Extract the Tube

Gently remove the end caps, flanges, or seals. Slide the process tube out of the furnace body with slow, steady pressure. Avoid any sharp impacts or flexing, especially with brittle materials like quartz or alumina.

Choosing Your Cleaning Method

The right technique depends entirely on what you need to remove. Start with the least aggressive method first.

For Loose Debris and Light Soot

This is the simplest scenario. A long-handled, soft-bristled brush (never metal, which can scratch the tube) can be used to gently push out any loose powders or flakes. A clean, dry cloth on a rod can also be effective.

For Organic Residue or Heavy Carbon

A thermal bake-out is often the most effective method. Place the empty tube back in the furnace, introduce a slow flow of air or oxygen, and ramp the temperature to a point sufficient to combust the residue (e.g., 600-800°C), but well below the tube's softening point.

For Stubborn Chemical Films

If a bake-out is ineffective, a chemical wash may be required.

- Start with basic solvents like isopropyl alcohol or acetone to remove soluble organic films.

- If that fails, a mild acid wash (e.g., dilute nitric or hydrochloric acid) can remove many metallic and inorganic residues.

- After any chemical wash, you must rinse the tube thoroughly multiple times with deionized (DI) water to remove all acid traces.

Understanding the Trade-offs and Risks

Aggressive cleaning can cause more harm than good if not performed correctly. Understanding the limitations is key to preserving your equipment.

The Danger of Thermal Shock

Never place a wet or cold tube into a hot furnace. The rapid temperature change will create stress and cause it to crack. Any tube that has been wet-cleaned must be dried completely before being returned to service.

Chemical and Material Incompatibility

Harsh chemicals can damage the tube itself. For instance, hydrofluoric (HF) acid will rapidly etch a quartz tube, and strong bases can harm alumina. Always verify that your chosen cleaning agent is compatible with your specific tube material.

The Risk of Abrasive Damage

Never use steel wool, metal brushes, or abrasive powders to clean a furnace tube, especially quartz. Scratches create stress concentration points that significantly increase the likelihood of the tube cracking or failing under high temperatures or vacuum.

Making the Right Choice for Your Goal

After cleaning, ensure the tube is fully dry, often by placing it in a low-temperature drying oven. Reinstall it carefully, ensuring all seals and flanges are secure to prevent leaks.

- If your primary focus is removing carbon or organic films: A high-temperature bake-out with a controlled flow of air is the safest and most effective starting point.

- If your primary focus is removing loose powders: Gentle mechanical cleaning with a soft brush or cloth after the tube has been safely removed is your best option.

- If your primary focus is removing stubborn inorganic residue: A chemical wash is necessary, but you must prioritize safety and confirm chemical compatibility with your tube material before proceeding.

A meticulously cleaned process tube is the foundation for achieving reliable and repeatable results in your work.

Summary Table:

| Cleaning Method | Best For | Key Consideration |

|---|---|---|

| Thermal Bake-out | Organic residue, heavy carbon | Use air/oxygen flow; stay below tube's softening point |

| Chemical Wash | Stubborn inorganic films | Verify chemical compatibility; rinse thoroughly with DI water |

| Mechanical Cleaning | Loose debris, light soot | Use soft-bristled brushes only; avoid abrasives |

Need a reliable tube furnace or expert advice on maintenance? KINTEK specializes in high-quality lab equipment and consumables, serving all your laboratory needs. Our team can help you select the right furnace tube and provide guidance on proper cleaning protocols to extend your equipment's lifespan and ensure optimal performance. Contact us today for personalized support!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the pressure on a tube furnace? Essential Safety Limits for Your Lab

- How do I choose a tube furnace? A Guide to Matching Your Process Needs

- What factors influence the general design of a tube furnace? Match Your Process with the Perfect System

- What are the advantages of using an alumina liner in a tube furnace for biomass combustion corrosion simulations?

- Why is an Alumina Ceramic Tube Support Necessary for 1100°C Experiments? Ensure Data Accuracy and Chemical Inertness