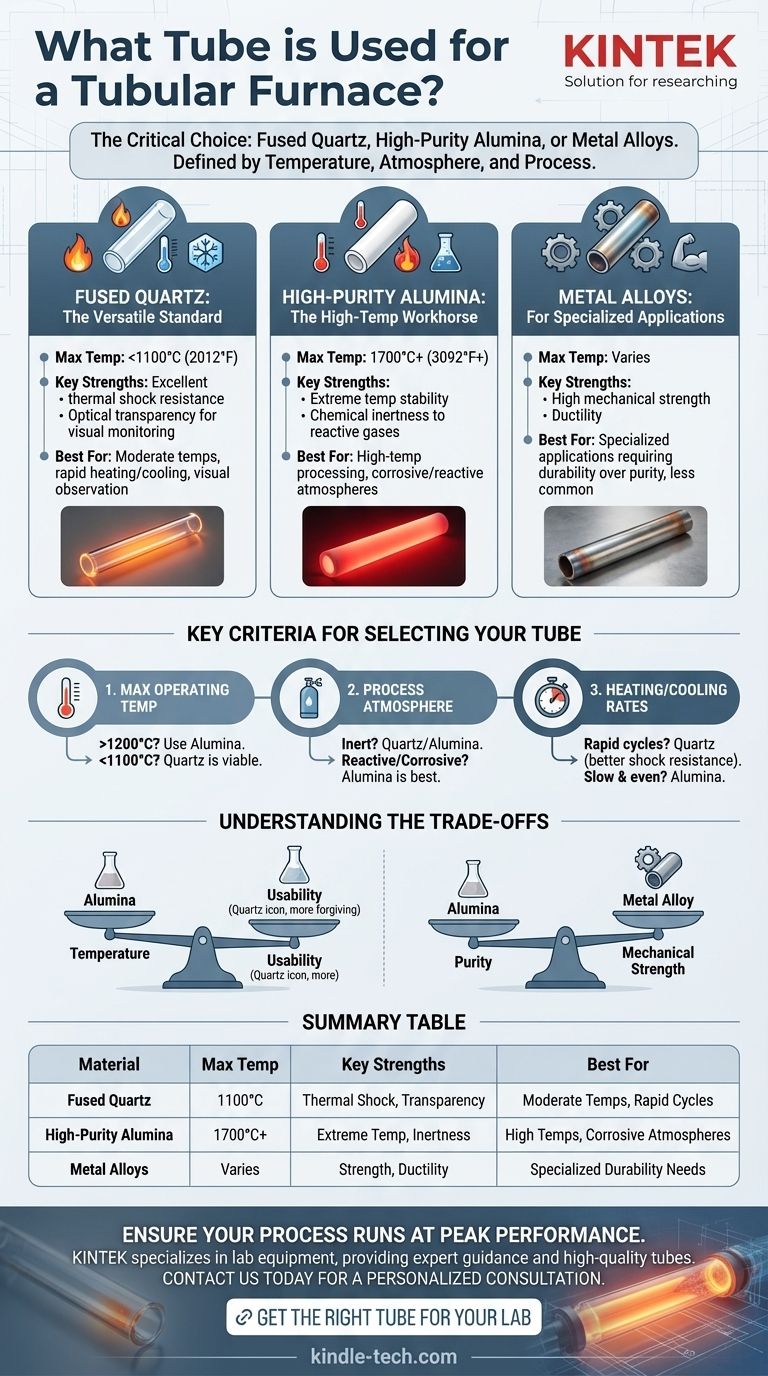

The most common tubes used in laboratory tube furnaces are made from fused quartz, high-purity alumina (a ceramic), or, less frequently, specialized metal alloys. There is no single "correct" tube material; the choice is a critical decision dictated entirely by the maximum operating temperature, the chemical atmosphere, and the sample being processed within the furnace.

Selecting the furnace tube is not a minor detail—it is the central decision that defines the operational limits of your entire process. The material you choose directly impacts the maximum temperature you can achieve, the gases you can use, and the overall reliability of your experiment.

Why Tube Material is the Core of the Furnace

A tube furnace's primary function is to create a precisely controlled high-temperature environment. The tube itself acts as the containment vessel for this environment, separating the sample and process atmosphere from the external heating elements.

The material of this tube must therefore withstand the thermal stress of heating, remain chemically stable in the presence of various gases, and not react with the sample being heated.

Fused Quartz: The Versatile Standard

Fused quartz is a popular choice for its excellent thermal shock resistance and optical transparency, which allows for visual monitoring of the process. It is a cost-effective and reliable option for many applications.

Its primary limitation is temperature. Most quartz tubes should not be used for sustained periods above 1100°C (2012°F), as they will begin to soften and devitrify (crystallize), leading to failure.

High-Purity Alumina: The High-Temperature Workhorse

For processes requiring temperatures above 1200°C, high-purity alumina (Al₂O₃) ceramic is the standard material. These opaque, white tubes are exceptionally stable at very high temperatures, often rated for use up to 1700°C (3092°F) or even higher.

Alumina is also highly resistant to chemical attack, making it suitable for a wide range of inert and reactive gas atmospheres. Its main drawback is its relative brittleness and lower resistance to severe thermal shock compared to quartz.

Metal Alloys: For Specialized Applications

In some specific cases, tubes made from high-temperature metal alloys (like Inconel) are used. These are chosen when mechanical strength and ductility are more important than extreme temperature or chemical purity.

However, metals are far more likely to react with process gases or outgas impurities at high temperatures, which can contaminate the sample. They are generally not suitable for the highest temperature ranges where ceramics excel.

Key Criteria for Selecting Your Tube

Your choice should be a deliberate one based on three critical factors. Answering these questions will guide you to the correct material.

1. What is your Maximum Operating Temperature?

This is the first and most important filter. If your process requires temperatures above 1200°C, you must use an alumina tube. For processes below 1100°C, quartz is a viable and often preferable option.

2. What is your Process Atmosphere?

The tube must be inert to the gases you plan to use. While both quartz and alumina are stable in inert atmospheres like argon and nitrogen, certain reactive or corrosive gases demand specific materials.

As a rule, highly reactive gases are best handled in non-metallic ceramic tubes like alumina to prevent unwanted reactions that can occur with quartz or metal at high temperatures.

3. How Rapid are your Heating and Cooling Rates?

Thermal shock is the stress a material endures when its temperature changes rapidly, which can cause cracking. Quartz is significantly more resistant to thermal shock than alumina.

If your process involves very fast heating or cooling cycles, a quartz tube is a safer choice, provided you stay within its temperature limits. Alumina tubes must be heated and cooled slowly and evenly to prevent fracture.

Understanding the Trade-offs

There is no universally "best" tube material. The choice is always a balance of performance, limitations, and cost.

Temperature vs. Usability

While alumina offers superior temperature performance, it is more fragile and requires more careful handling and programming of heating rates. Quartz is more forgiving to rapid temperature changes but is limited to lower-temperature work.

Purity vs. Mechanical Strength

Ceramics like alumina offer exceptional chemical purity at high temperatures. Metals offer superior mechanical strength and ductility but are generally more reactive and prone to contaminating a sensitive process.

Making the Right Choice for Your Goal

Base your decision on the single most critical factor for your specific application.

- If your primary focus is high-temperature processing (>1200°C): High-purity alumina is the only suitable and reliable choice.

- If your primary focus is visual observation and moderate temperatures (<1100°C): Fused quartz offers the best combination of visibility, thermal shock resistance, and cost.

- If your primary focus is working with corrosive or reactive atmospheres: High-purity alumina provides the chemical inertness needed to ensure process purity.

- If your primary focus is rapid heating/cooling cycles: Fused quartz is the safer material due to its superior resistance to thermal shock.

Choosing the right tube material ensures the safety, reliability, and success of your high-temperature work.

Summary Table:

| Material | Max Temperature | Key Strengths | Best For |

|---|---|---|---|

| Fused Quartz | 1100°C (2012°F) | Excellent thermal shock resistance, visual transparency | Moderate temperatures, rapid heating/cooling, visual monitoring |

| High-Purity Alumina | 1700°C+ (3092°F+) | Extreme temperature stability, chemical inertness | High-temperature processing, corrosive/reactive atmospheres |

| Metal Alloys | Varies | High mechanical strength, ductility | Specialized applications requiring durability over purity |

Ensure Your Process Runs at Peak Performance

Choosing the right tube is critical for the safety and success of your high-temperature applications. The wrong material can lead to tube failure, contaminated samples, or failed experiments.

KINTEK specializes in lab equipment and consumables, providing expert guidance and high-quality tubes tailored to your specific needs—whether you require the thermal shock resistance of quartz or the high-temperature capabilities of alumina.

Let our experts help you select the perfect tube for your furnace. We'll ensure you get a reliable solution that matches your temperature, atmosphere, and process requirements.

Contact us today for a personalized consultation and get the right tube for your lab.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Vertical Laboratory Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- Why is an Alumina Ceramic Tube Support Necessary for 1100°C Experiments? Ensure Data Accuracy and Chemical Inertness

- Why is a horizontal alumina tube furnace ideal for mixed gas corrosion at 650 °C? Ensure Pure Experimental Integrity

- How do you clean a tube furnace tube? A Step-by-Step Guide to Safe and Effective Cleaning

- What is the ceramic tube high temperature? From 1100°C to 1800°C, Choose the Right Material

- What is the physical description of a tube furnace? A Detailed Breakdown of its High-Temperature Design