No, CVD diamonds are not fake. They are real diamonds in every scientific sense of the word. A CVD diamond possesses the exact same chemical, physical, and optical properties as a diamond mined from the earth. The only difference is their origin.

The core distinction is not between "real" and "fake," but between "mined" and "grown." A CVD diamond is a true diamond from its atomic structure to its brilliance, differing only in that it was created in a controlled laboratory environment rather than deep within the Earth's crust.

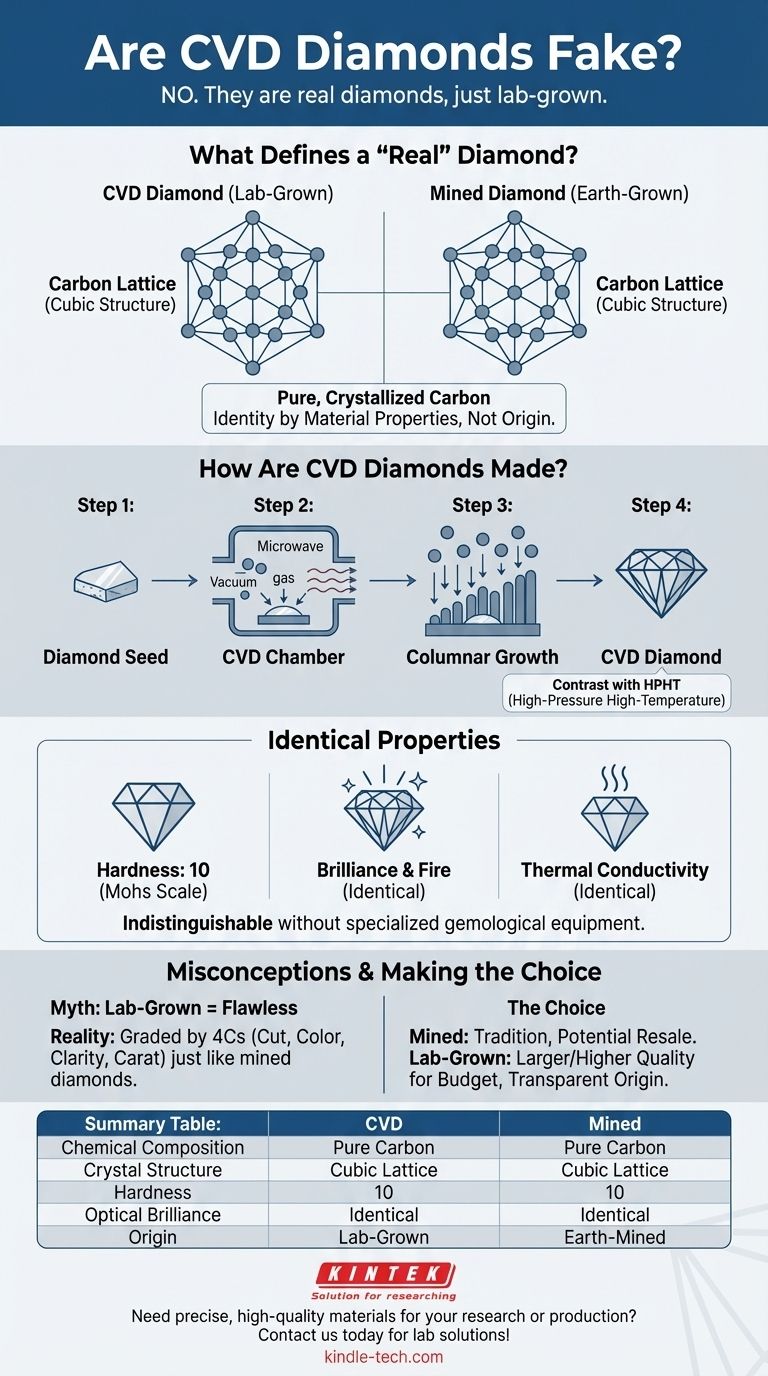

What Defines a "Real" Diamond?

To understand why a CVD diamond is authentic, we must first define what a diamond is. The identity of a diamond is determined by its material properties, not its origin.

The Unchanging Atomic Structure

At a molecular level, a diamond is simply carbon crystallized in a specific cubic lattice structure. This unique arrangement of atoms is what gives a diamond its unparalleled hardness and brilliance.

CVD diamonds are made of the same pure, crystallized carbon. They are not simulants like cubic zirconia or moissanite, which are made of entirely different materials.

Identical Physical and Optical Properties

Because their atomic structure is identical, CVD diamonds exhibit the same properties as mined diamonds. This includes:

- Hardness: A 10 on the Mohs scale, the hardest naturally occurring substance.

- Brilliance & Fire: The ability to refract and disperse light, creating the signature sparkle.

- Thermal Conductivity: The same heat dissipation properties, which is one way experts can test for authenticity.

Without specialized gemological equipment, even a trained expert cannot distinguish a lab-grown diamond from a mined one.

How Are CVD Diamonds Made?

The process of creating a CVD diamond is a feat of material science that replicates a natural process under highly controlled conditions. It stands in contrast to the billions of years of intense heat and pressure that form diamonds in the Earth's mantle.

The "Seed" of a Diamond

The process begins with a "seed," which is a very thin slice of a high-quality diamond. This seed acts as the template upon which the new diamond will grow.

The Chemical Vapor Deposition (CVD) Process

This seed is placed inside a sealed vacuum chamber. The chamber is heated and filled with a carbon-rich gas, such as methane.

High-power microwave energy breaks down the gas molecules, allowing pure carbon atoms to rain down and bond to the diamond seed. Layer by layer, the carbon atoms arrange themselves into the same crystal lattice, and the diamond grows in a columnar fashion.

Contrasting with HPHT

The other method for creating lab-grown diamonds is High-Pressure High-Temperature (HPHT). This process more closely mimics the conditions of the Earth's mantle, subjecting carbon to immense pressure and heat to force crystallization. CVD is a more recent and technologically advanced method.

Understanding the Trade-offs and Misconceptions

While CVD diamonds are physically real, it's crucial to understand their position in the market and correct common myths. Their value and characteristics have important nuances.

Myth: Lab-Grown Means "Flawless"

Because they are grown in a lab, many assume CVD diamonds are always perfect. This is not true. The growth process is a controlled replication of a natural phenomenon, and randomness can still introduce tiny imperfections or inclusions.

For this reason, CVD diamonds are graded by gemological labs using the same 4Cs (Cut, Color, Clarity, and Carat) as mined diamonds.

The Value Proposition

CVD diamonds are unequivocally real diamonds, but they typically cost significantly less than mined diamonds of comparable size and quality. This price difference is not due to inferiority but to supply. The mining process is resource-intensive and yields an unpredictable supply, while lab-grown diamonds can be produced reliably and at scale.

The Challenge of Identification

The fact that CVD diamonds are indistinguishable to the naked eye reinforces their authenticity. However, it also means that disclosure is critical. Reputable jewelers will always identify a diamond as lab-grown and provide a certificate from a grading lab that verifies its properties and origin.

Making the Right Choice for Your Goal

The decision between a mined and a lab-grown diamond is a personal one that depends on your priorities. Both are real diamonds, but they serve different values.

- If your primary focus is tradition and potential resale value: Mined diamonds have a century-long market history and a more established, though not guaranteed, secondary market.

- If your primary focus is maximizing size and quality for your budget: Lab-grown diamonds offer a significantly larger or higher-quality stone for the same price as a smaller mined equivalent.

- If your primary focus is a transparent and potentially more sustainable origin: Lab-grown diamonds provide a clear chain of custody and bypass the environmental and ethical concerns associated with some mining operations.

Ultimately, choosing a CVD diamond is choosing a stone that is physically and chemically identical to its mined counterpart, created through human ingenuity.

Summary Table:

| Property | CVD Diamonds | Mined Diamonds |

|---|---|---|

| Chemical Composition | Pure Carbon (C) | Pure Carbon (C) |

| Crystal Structure | Cubic Lattice | Cubic Lattice |

| Hardness (Mohs Scale) | 10 | 10 |

| Optical Brilliance | Identical | Identical |

| Origin | Lab-Grown | Mined from Earth |

Need precise, high-quality materials for your research or production? KINTEK specializes in advanced lab equipment and consumables, including materials for cutting-edge applications like diamond synthesis. Our expertise ensures you get reliable, high-performance solutions tailored to your laboratory's needs. Contact us today to learn how we can support your projects with the right tools and materials!

Visual Guide

Related Products

- CVD Diamond for Thermal Management Applications

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

People Also Ask

- What are the advantages of diamond cutting tool material? Achieve Superior Precision and Productivity

- What are the industrial uses of CVD diamond? Unlock Extreme Performance in Your Applications

- Do lab-grown diamonds last as long? Yes, They Offer the Same Unmatched Durability

- What is chemical vapor deposition of diamond? Grow High-Purity Diamonds Atom-by-Atom

- Are CVD diamonds real diamonds? Unveiling the Truth About Lab-Grown vs. Mined Diamonds

- How do scientists grow diamonds? Replicating Nature's Process in a Lab

- How long does it take to synthesize a diamond? The Trade-Off Between Speed and Gem Quality

- What are the advantages and applications of MPCVD? The Gold Standard for High-Purity Single-Crystal Diamond Growth