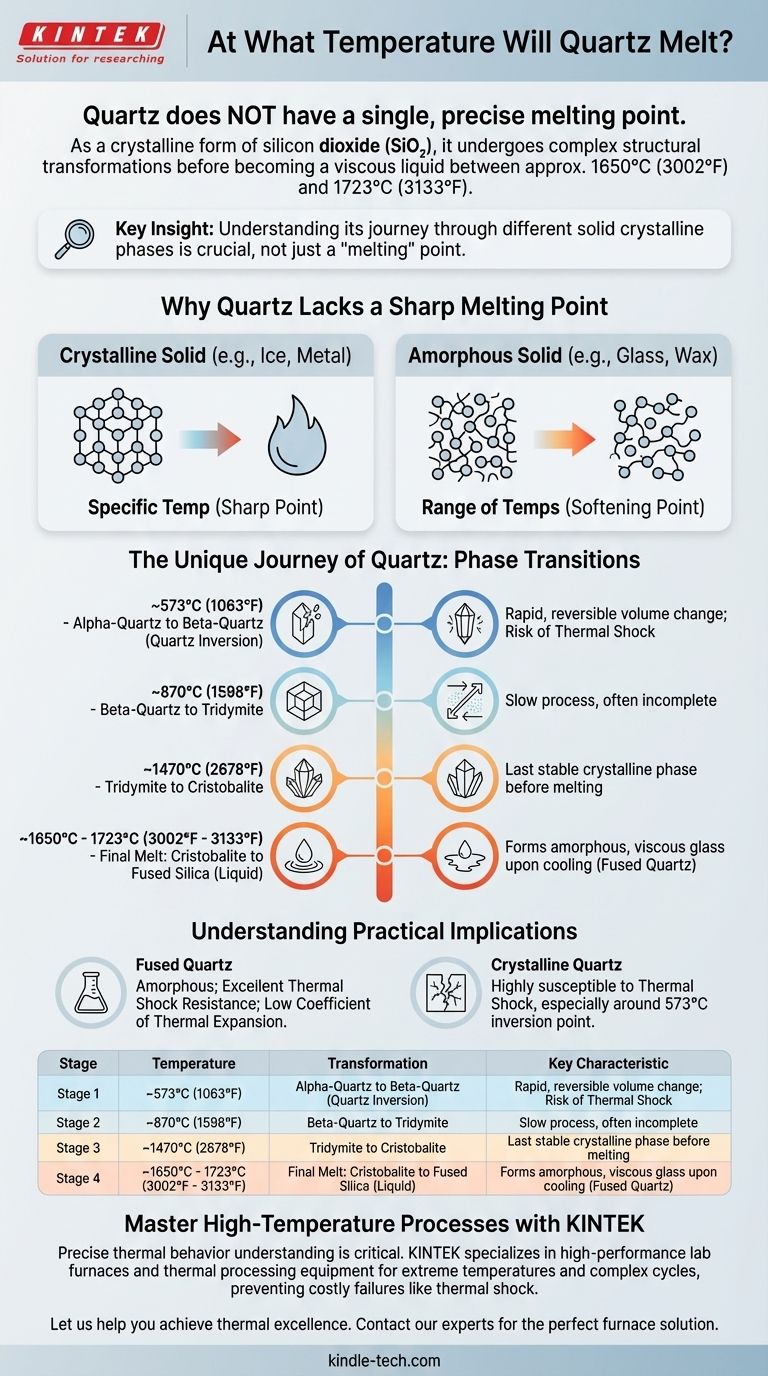

Unlike many common materials, quartz does not have a single, precise melting point. As a crystalline form of silicon dioxide (SiO₂), it undergoes a series of structural transformations at high temperatures before finally becoming a liquid. The final melting into a viscous fluid occurs at a temperature range between approximately 1650°C (3002°F) and 1723°C (3133°F).

The critical takeaway is that asking when quartz "melts" is misleading. Instead, you must understand its journey through different solid crystalline phases at progressively higher temperatures before it finally loses its structure and becomes a liquid glass.

Why Quartz Lacks a Sharp Melting Point

To grasp the behavior of quartz, we must first distinguish between two types of solids and how they respond to heat. This distinction is fundamental to its high-temperature properties.

Crystalline vs. Amorphous Solids

A crystalline solid, like ice or a metal, has a highly ordered, repeating atomic structure. When heated, the bonds in this rigid lattice break simultaneously at a specific temperature, resulting in a sharp, defined melting point.

An amorphous solid, like glass or wax, has a disordered, random atomic structure. When heated, it gradually softens over a range of temperatures, becoming less viscous until it flows freely. This is known as a softening point, not a melting point.

The Unique Journey of Quartz

Quartz begins as a crystalline solid, but it doesn't melt in a simple, direct way. The strong silicon-oxygen bonds that form its crystal lattice resist breaking down.

Instead of melting, the crystal structure rearranges itself into new, more stable solid forms as the temperature rises. These are known as phase transitions.

The High-Temperature Transformations of Quartz

The path from room-temperature quartz to a molten liquid is a multi-stage process. Each stage represents a distinct crystalline structure with different properties.

Stage 1: Alpha-Quartz to Beta-Quartz (~573°C / 1063°F)

This is the first and most well-known transformation. The crystal structure subtly shifts from alpha-quartz to beta-quartz.

This change, often called the "quartz inversion," is rapid and reversible. It involves a slight but sudden change in volume, which is a critical factor in geology and ceramics as it can induce stress and cracking.

Stage 2: Transformation to Tridymite (~870°C / 1598°F)

As temperatures increase further, beta-quartz will slowly and reluctantly transform into a different crystalline structure called tridymite. This transformation is sluggish and often requires very long heating times to occur completely.

Stage 3: Transformation to Cristobalite (~1470°C / 2678°F)

At even higher temperatures, tridymite rearranges into cristobalite. This is the final stable crystalline form of SiO₂ before melting. Like the previous transition, this process is slow.

The Final Melt: Fused Silica (~1650°C - 1723°C)

Finally, in this temperature range, the crystalline structure of cristobalite breaks down completely. The material becomes a highly viscous, amorphous liquid.

When this liquid cools, it does not return to a crystalline quartz structure. It solidifies into an amorphous glass known as fused quartz or fused silica.

Understanding the Practical Implications

This complex behavior has significant consequences in science and industry. The distinction between crystalline quartz and its melted-and-cooled form, fused quartz, is crucial.

Fused Quartz vs. Crystalline Quartz

Fused quartz is prized for its extremely low coefficient of thermal expansion. Because it is amorphous, it can withstand rapid and extreme temperature changes without cracking—a property known as excellent thermal shock resistance.

Crystalline quartz, by contrast, is highly susceptible to thermal shock, particularly around the 573°C inversion point.

The Risk of Thermal Shock

For anyone working with materials that contain quartz, such as firing ceramics or studying geological formations, the 573°C alpha-beta transition is a critical threshold. Heating or cooling too quickly through this point will almost certainly cause the material to fracture.

How to Apply This to Your Goal

Your focus should shift from a single melting point to the specific transition that matters for your application.

- If your primary focus is geology or ceramics: Be most aware of the 573°C alpha-beta transition, as the sudden volume change is the primary cause of cracking during heating and cooling cycles.

- If your primary focus is manufacturing or material science: Concentrate on the final melting range around 1700°C for processes that create fused silica, a material valued for its exceptional thermal stability and optical clarity.

Understanding this sequence of transformations is the key to predicting and controlling the behavior of quartz at any temperature.

Summary Table:

| Stage | Temperature | Transformation | Key Characteristic |

|---|---|---|---|

| 1. Quartz Inversion | ~573°C (1063°F) | Alpha-Quartz → Beta-Quartz | Rapid, reversible volume change; risk of thermal shock |

| 2. Slow Transformation | ~870°C (1598°F) | Beta-Quartz → Tridymite | Slow process, often incomplete |

| 3. Final Crystalline Form | ~1470°C (2678°F) | Tridymite → Cristobalite | Last stable crystalline phase before melting |

| 4. Final Melt | ~1650°C - 1723°C (3002°F - 3133°F) | Cristobalite → Fused Silica (Liquid) | Forms an amorphous, viscous glass upon cooling |

Master High-Temperature Processes with KINTEK

Understanding the precise thermal behavior of materials like quartz is critical for success in your lab. Whether you're developing new ceramics, studying geological samples, or manufacturing high-purity glass, the right equipment ensures accuracy and prevents costly failures like thermal shock.

KINTEK specializes in high-performance lab furnaces and thermal processing equipment designed to handle extreme temperatures and complex heating cycles with precision. Our solutions help you safely navigate quartz's phase transitions and achieve consistent, reliable results.

Let us help you achieve thermal excellence. Contact our experts today to find the perfect furnace for your specific application and material challenges.

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is reactive magnetron sputtering? A Versatile Method for Thin-Film Synthesis

- What equation do you use to calculate the heat required to melt a sample? Master the Heat of Fusion Formula

- Will THC distillate dissolve in water? Unlocking the Science of Water-Soluble Cannabis

- What function does a constant temperature shaker perform during adsorption performance tests? Ensure Data Accuracy

- What is film uniformity? The Key to Consistent Device Performance and Yield

- How well does graphite transfer heat? Unlock Superior Thermal Management for Your Electronics

- What is the density of synthetic graphite? Understanding the Range from 1.5 to 2.26 g/cm³

- What is the problem with plastic pyrolysis? Key Challenges and Environmental Trade-offs