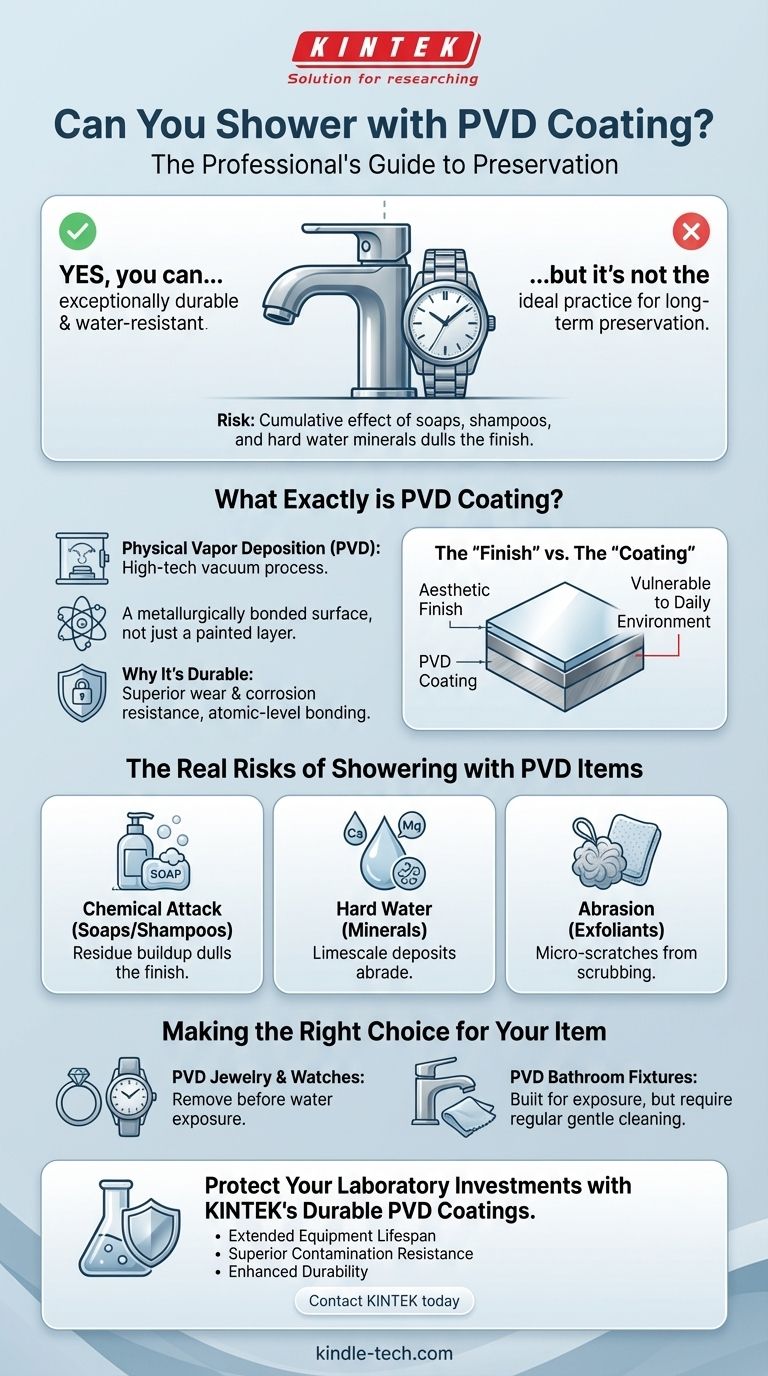

Yes, you can, but it is not the ideal practice for long-term preservation. While Physical Vapor Deposition (PVD) creates an exceptionally durable and water-resistant coating, you should generally avoid showering with PVD-coated items like jewelry or watches. The true risk isn't from the water itself, but from the cumulative effect of chemicals in soaps, shampoos, and minerals in hard water, which can dull the finish and degrade its luster over time.

The core issue is not whether the PVD coating will survive the water, but how to preserve its aesthetic finish. PVD is incredibly resilient, but consistent exposure to chemicals and mineral deposits from showering is the primary cause of a dulled, faded, or clouded appearance.

What Exactly is PVD Coating?

To understand the risks, it's important to first understand what PVD coating is and why it's so highly regarded for its durability.

A Layer of Vapor, Not Paint

Physical Vapor Deposition (PVD) is a high-tech vacuum coating process. Inside a vacuum chamber, a solid material (often a durable metal like titanium or zirconium) is vaporized into its plasma state and then bonded molecule by molecule onto the surface of the base material (like stainless steel or brass).

This process doesn't just paint a layer on top; it creates a new, metallurgically bonded surface that is incredibly thin yet exceptionally hard and dense.

Why It's So Durable

The primary benefit of PVD is its superior wear and corrosion resistance. Because the coating is bonded at an atomic level, it is far less likely to chip, fade, or peel compared to traditional methods like electroplating.

This makes it highly resistant to scratches, tarnishing, and damage from environmental factors.

The "Finish" vs. The "Coating"

A critical distinction must be made between the physical integrity of the coating and its visual finish. The PVD coating itself can withstand significant stress. However, the pristine, high-luster finish is what is most vulnerable to the daily environment of a shower.

The Real Risks of Showering with PVD Items

The occasional shower won't destroy a PVD-coated item, but making it a daily habit introduces several factors that will degrade its appearance.

The Chemical Attack from Soaps

Soaps, body washes, and shampoos contain a variety of chemicals, oils, and surfactants. These substances can leave behind a thin film of residue, slowly building up and making the PVD surface appear dull or cloudy.

The Problem with Hard Water

If you live in an area with hard water, this is a significant threat. Hard water is rich in minerals like calcium and magnesium, which leave behind chalky white deposits known as limescale.

These deposits are abrasive and difficult to remove without using harsh chemicals or scrubbing, both of which can damage the PVD finish with micro-scratches.

Abrasion from Exfoliants

While PVD is highly scratch-resistant, it is not scratch-proof. Abrasive materials like loofahs, washcloths, and exfoliating scrubs can create thousands of microscopic scratches that, over time, will dull the reflective quality of the finish.

Understanding the Trade-offs

PVD is a superior coating technology, but it's important to manage expectations and understand its place relative to other materials.

PVD vs. Standard Plating

Compared to traditional electroplating (often seen in lower-cost jewelry), PVD is in a different league. It is significantly more durable, harder, and longer-lasting. Plating can wear away from simple friction, whereas PVD resists it.

PVD vs. Solid Materials

For bathroom and kitchen fixtures designed for constant water exposure, PVD is an excellent choice. A PVD-coated stainless steel faucet is designed to handle this environment, though it still requires regular cleaning to prevent mineral buildup.

However, a piece of PVD-coated jewelry is not the same as a solid gold ring. The goal with decorative items is to preserve the beauty of the finish, which requires more careful handling.

Making the Right Choice for Your Item

The decision to expose a PVD-coated item to water depends entirely on what the item is and what your priority is.

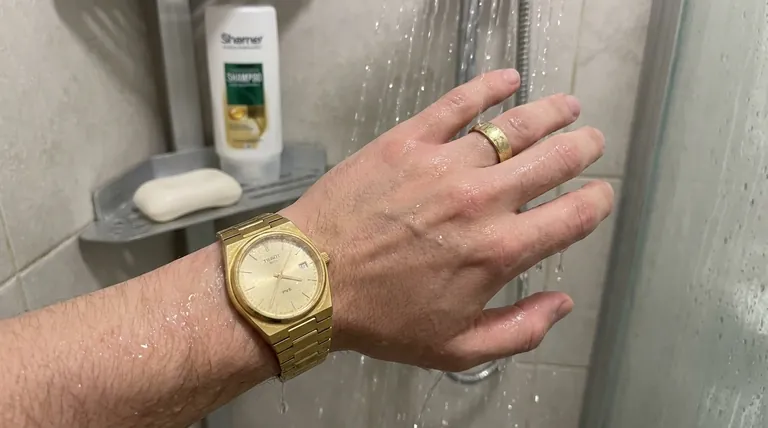

- If you have PVD jewelry (watches, rings, necklaces): Always remove it before showering, swimming, or applying lotions. This is the single best way to protect its color and luster for years to come.

- If you have PVD bathroom fixtures (faucets, showerheads): These are built for this environment. Your focus should be on regular, gentle cleaning with a soft cloth and mild soap to prevent the buildup of soap scum and hard water minerals.

- If your primary goal is maximum longevity for any item: Treat the PVD coating with care. Avoiding routine exposure to chemicals and abrasive elements is the key to preserving its original finish.

By understanding that PVD's true vulnerability lies in its aesthetic finish rather than its structural integrity, you can ensure your items retain their beauty for their entire lifespan.

Summary Table:

| Factor | Impact on PVD Coating | Recommendation |

|---|---|---|

| Water Exposure | Minimal direct damage to the coating itself. | Occasional exposure is acceptable. |

| Soaps & Shampoos | Chemicals can leave a dulling film over time. | Avoid consistent, daily exposure. |

| Hard Water Minerals | Limescale deposits can abrade and cloud the finish. | A significant threat; remove items before showering. |

| Abrasive Loofahs/Cloths | Can cause micro-scratches that dull the luster. | Prevent physical contact during cleaning routines. |

Protect your laboratory investments with KINTEK's durable PVD coatings.

Just as you protect your jewelry from harsh chemicals, your lab equipment deserves the same care. KINTEK specializes in high-performance PVD coatings for lab equipment and consumables, offering superior wear and corrosion resistance to extend the life of your critical tools.

Our coatings ensure:

- Extended Equipment Lifespan: Reduce replacement costs and downtime.

- Superior Contamination Resistance: Protect sensitive experiments and processes.

- Enhanced Durability: Withstand harsh lab environments and cleaning protocols.

Let our expertise in lab-grade PVD solutions safeguard your valuable equipment. Contact KINTEK today to discuss how we can enhance your laboratory's capabilities and protect your investments.

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Custom PTFE Teflon Parts Manufacturer for PTFE Tweezers

People Also Ask

- What safety precautions would you have to consider during quench? Ensure Safe Vacuum Oil Quenching with Nitrogen Control

- What happens to heat generated in a vacuum? Mastering Thermal Control for Superior Materials

- Can I vacuum the inside of my furnace? A Guide to Safe DIY Cleaning vs. Professional Service

- What is the purpose of vacuum heat treatment? Achieve Superior Metallurgical Purity and Performance

- What are the advantages of vacuum firing? Achieve Ultimate Material Purity and Performance