Yes, zirconia can be milled. However, the critical detail lies not in if it can be milled, but in what state it is milled. The standard industrial and dental practice is to mill zirconia in its soft, chalk-like "green state" before it undergoes a final hardening process.

The ability to mill zirconia is defined by its two distinct material states: a soft, pre-sintered form that is easy to machine, and a hard, fully sintered form that is extremely difficult. The entire fabrication process is designed around milling the soft material and then precisely compensating for the significant shrinkage that occurs during final hardening.

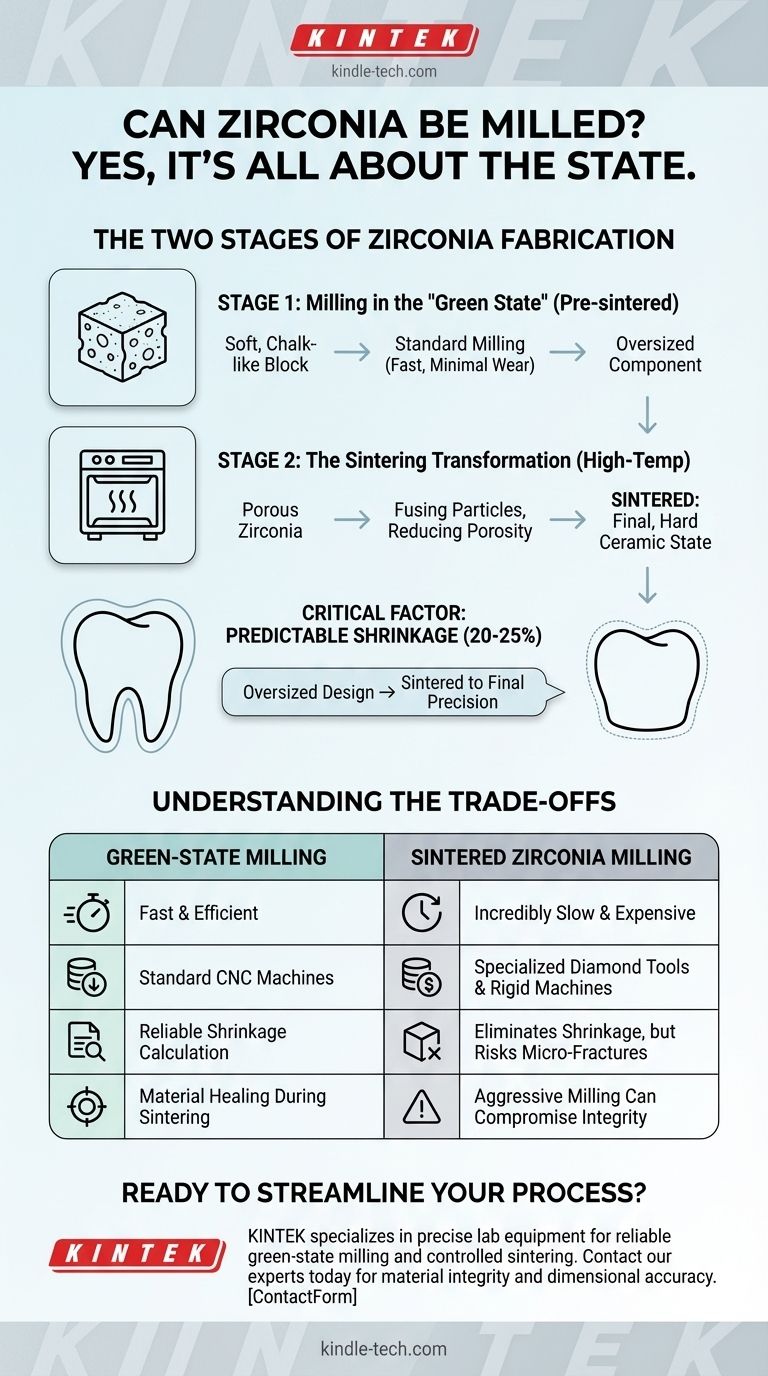

The Two Stages of Zirconia Fabrication

To understand zirconia milling, you must first understand its transformation from a soft, workable material into one of the hardest ceramics available. This process dictates the entire manufacturing workflow.

Stage 1: Milling in the "Green State"

The overwhelming majority of zirconia components are machined in their pre-sintered or "green" state.

In this stage, the zirconia exists as a porous, chalk-like block. It is soft enough to be shaped quickly and easily by standard milling machines with minimal tool wear. This is the most efficient and cost-effective method for fabrication.

Stage 2: The Sintering Transformation

After the component has been milled to its desired shape from the green-state block, it undergoes sintering.

Sintering is a high-temperature process where the porous zirconia is heated, causing the particles to fuse together. This process drastically reduces porosity and increases the material's density, resulting in its final, exceptionally hard state.

The Critical Factor: Shrinkage

As noted in manufacturing data, the most significant event during sintering is predictable shrinkage.

The zirconia part will shrink by as much as 20-25% in a highly uniform manner. To account for this, the initial design is oversized by a precise factor in the CAD/CAM software before milling. The part is intentionally milled larger so that it shrinks to the exact required dimensions after sintering.

Understanding the Trade-offs

Choosing when to mill zirconia involves a clear set of engineering and economic trade-offs. While technically possible to mill fully sintered zirconia, it is rarely practical.

Speed and Equipment Cost

Milling green-state zirconia is fast and can be done on a wide range of standard CNC milling machines.

Milling fully sintered zirconia is incredibly slow and requires specialized, highly rigid machines and expensive diamond-coated tools to even attempt. The wear on the equipment is extreme.

Precision and Predictability

The green-state method relies entirely on the software's ability to accurately calculate shrinkage. For most applications, this is highly reliable and produces clinically or industrially acceptable results.

Milling a fully sintered block eliminates the shrinkage variable, but the process itself can introduce stress and micro-fractures into the super-hard material, potentially compromising its integrity.

Material Integrity

The sintering process heals any minor surface imperfections from the green-state milling, resulting in a uniformly strong final part.

Aggressive milling on a fully hardened zirconia block risks creating defects that cannot be repaired, leading to a weaker component. The use of zirconia beads during sintering helps ensure this transformation happens uniformly, preventing warping as the material shrinks.

How to Apply This to Your Project

The correct approach is almost always determined by the desired outcome and production volume.

- If your primary focus is dental restorations or volume manufacturing: Green-state milling is the only commercially viable method. Its efficiency, speed, and reliability are the industry standard.

- If your primary focus is a highly specific industrial prototype where shrinkage cannot be tolerated: You might explore milling fully sintered zirconia, but you must be prepared for extreme costs, long lead times, and the need for highly specialized machining partners.

Ultimately, mastering zirconia fabrication is not about forcing tools against a hard material, but about understanding and leveraging its transformative properties.

Summary Table:

| Milling Stage | Material State | Key Characteristics | Common Use Cases |

|---|---|---|---|

| Green-State Milling | Pre-sintered, chalk-like | Soft, easy to machine, minimal tool wear | Dental restorations, volume manufacturing |

| Sintered Zirconia Milling | Fully hardened ceramic | Extremely hard, slow, requires diamond tools | Specialized industrial prototypes |

Ready to streamline your zirconia fabrication process? KINTEK specializes in providing the precise lab equipment and consumables needed for reliable green-state milling and controlled sintering. Whether you're in dental manufacturing or industrial R&D, our solutions ensure material integrity and dimensional accuracy. Contact our experts today to discuss how we can support your project with tailored equipment and expert guidance.

Visual Guide

Related Products

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Sealed Hammer Crusher for Efficient Sample Preparation

- High Energy Vibratory Laboratory Ball Mill Double Tank Type

- Laboratory Grinding Mill Mortar Grinder for Sample Preparation

- Laboratory Horizontal Planetary Ball Mill Milling Machine

People Also Ask

- What are the factors affecting grinding operation? Master the Variables for Optimal Performance

- How many types of ball mills are there? Choose the Right Mill for Your Lab or Industry

- How does precision grinding equipment ensure measurement accuracy? Master Metallographic Prep for Spherical Steel

- Why is it necessary to use ultrafine grinding equipment for boron carbide? Achieve High Density in Hard Ceramics

- How does ball milling equipment influence powder metallurgy? Master Superalloy Preparation & Precision Modeling

- Which is the mill preferred for wet grinding? Choose the Right Mill for Your Particle Size Goal

- Why is an intermediate grinding step necessary for solid-state synthesis? Achieving Phase Purity in Niobates

- Why is an agate mortar and pestle preferred for grinding MAX phase? Ensure Sample Purity & Zero Contamination