When done correctly, a modern porcelain crown can look so natural that it is virtually indistinguishable from a real tooth. The success of the restoration depends entirely on the type of material used, the skill of the dentist performing the procedure, and the artistry of the dental laboratory technician crafting the crown.

The natural appearance of a porcelain crown is not a given; it is a result of choosing the right metal-free material and partnering with a skilled dental team that understands the nuances of light, color, and shape.

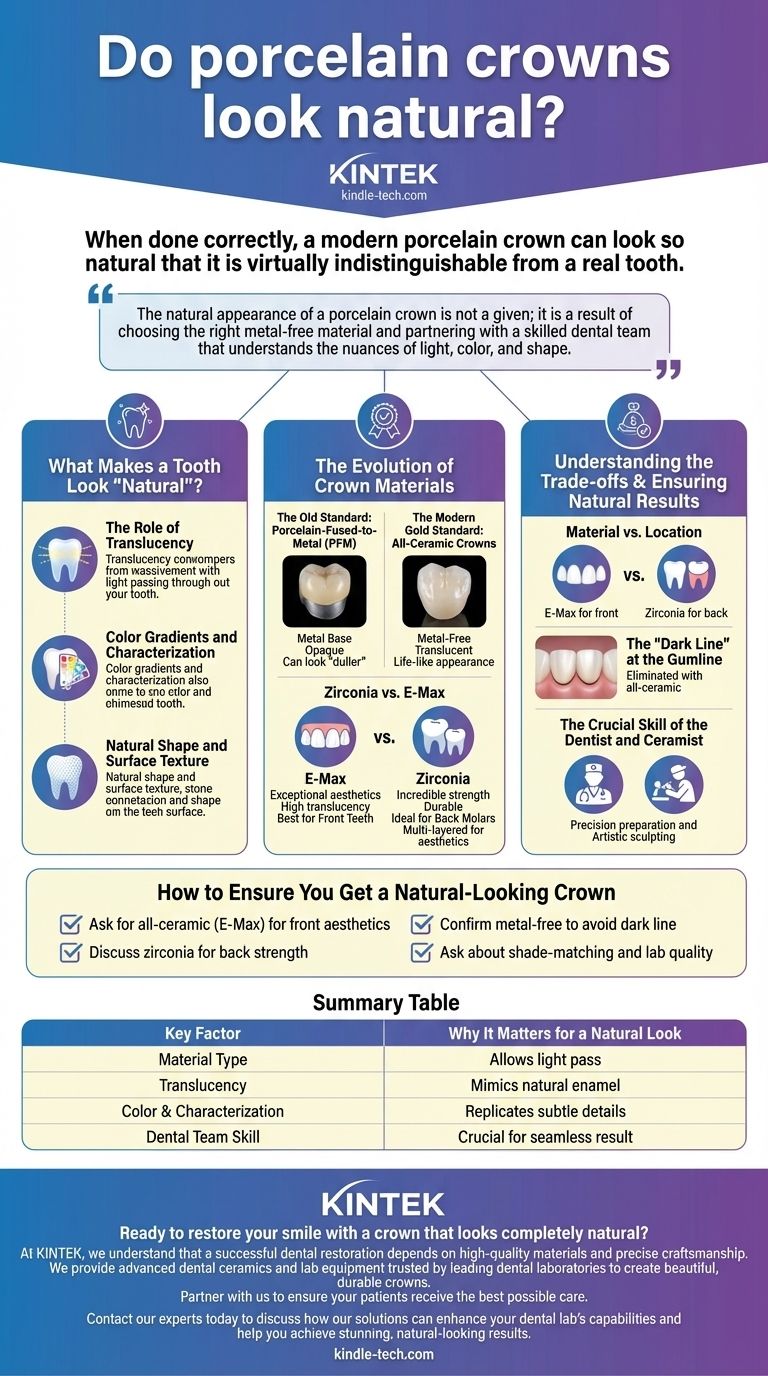

What Makes a Tooth Look "Natural"?

To understand why some crowns look better than others, we first must define what makes a natural tooth look alive and real. It comes down to a few key optical properties.

The Role of Translucency

A natural tooth is not fully opaque. It has a degree of translucency, meaning it allows some light to pass through it, particularly at the incisal (biting) edge. This property gives the tooth depth and vitality.

A crown that is too opaque will block light, making it look flat, lifeless, and obviously artificial.

Color Gradients and Characterization

No tooth is a single, uniform color. Natural teeth have subtle color gradients, often being slightly darker or more yellow near the gumline and more translucent and lighter towards the tip.

They also have unique "characterizations"—tiny craze lines, slight discolorations, or white spots that make them unique. A masterfully crafted crown will replicate these subtle details.

Natural Shape and Surface Texture

Real teeth are not perfectly smooth. They have faint vertical ridges and developmental grooves that reflect light in complex ways. A crown that is shaped and textured to match the surrounding teeth will blend in seamlessly.

The Evolution of Crown Materials

The type of porcelain crown you receive has the single biggest impact on its natural appearance. The materials have evolved significantly over the years.

The Old Standard: Porcelain-Fused-to-Metal (PFM)

For decades, the most common type of crown was Porcelain-Fused-to-Metal (PFM). This crown has a metal alloy substructure that is covered with a layer of porcelain.

While strong, the metal base is completely opaque. It prevents any light from passing through the crown, which can make it look "duller" than adjacent natural teeth.

The Modern Gold Standard: All-Ceramic Crowns

Modern dentistry now favors all-ceramic or all-porcelain crowns. These crowns are made entirely of advanced ceramic materials like lithium disilicate (E-Max) or zirconia, with no metal core.

This metal-free construction allows light to pass through the crown much like a natural tooth, resulting in superior translucency and a life-like appearance.

Zirconia vs. E-Max

Within all-ceramic crowns, the two most popular materials are Zirconia and E-Max.

- E-Max (Lithium Disilicate) is renowned for its exceptional aesthetics and translucency. It is often the top choice for highly visible front teeth where appearance is paramount.

- Zirconia is known for its incredible strength and durability, making it an ideal choice for back molars that endure heavy chewing forces. While early versions were quite opaque, modern multi-layered zirconia has vastly improved aesthetics.

Understanding the Trade-offs

Choosing the right crown involves more than just picking the prettiest material. It's about balancing aesthetics, function, and longevity.

Material vs. Location

The choice between E-Max and zirconia often comes down to the tooth's location. The superior beauty of E-Max is perfect for front teeth, while the brute strength of zirconia is necessary for back molars. Your dentist will recommend the best material for your specific clinical need.

The "Dark Line" at the Gumline

A common fear is the appearance of a dark line at the gumline. This is a well-known issue with older PFM crowns. If the gums recede even slightly, the dark metal margin at the base of the crown can become visible.

This problem is completely eliminated with all-ceramic crowns. Since there is no metal, there is no dark line to expose, even if your gums recede over time.

The Crucial Skill of the Dentist and Ceramist

The most advanced material in the world will fail in the hands of an unskilled team. The dentist's precision in preparing the tooth and taking an accurate impression is critical.

Equally important is the artistry of the dental lab technician (ceramist) who physically sculpts, stains, and glazes the crown. Their ability to replicate the shape and subtle color variations of your natural teeth is what creates a truly seamless result.

How to Ensure You Get a Natural-Looking Crown

To achieve the best possible outcome, you must be an active participant in the process. Ask your dentist informed questions to ensure your goals are aligned.

- If your primary focus is aesthetics for a front tooth: Ask your dentist about using an all-ceramic crown like E-Max for its superior translucency.

- If your primary focus is strength for a back molar: Discuss zirconia as a durable, tooth-colored solution and ask if a modern, more esthetic version is appropriate.

- If you are concerned about a dark line at your gums: Confirm with your dentist that you are receiving a metal-free, all-ceramic crown to eliminate this possibility entirely.

- If you want the absolute best result: Ask your dentist about their shade-matching process and the quality of the dental laboratory they partner with.

By choosing the right material and the right dental team, you can get a crown that not only restores function but also beautifully restores confidence in your smile.

Summary Table:

| Key Factor | Why It Matters for a Natural Look |

|---|---|

| Material Type | All-ceramic crowns (E-Max, zirconia) allow light to pass through like a natural tooth, unlike older metal-based crowns. |

| Translucency | Mimics the light-transmitting quality of natural tooth enamel, creating depth and vitality. |

| Color & Characterization | Skilled technicians replicate subtle color gradients and unique details for a perfect match. |

| Dental Team Skill | The precision of the dentist and artistry of the lab technician are crucial for a seamless result. |

Ready to restore your smile with a crown that looks completely natural?

At KINTEK, we understand that a successful dental restoration depends on high-quality materials and precise craftsmanship. We provide advanced dental ceramics and lab equipment trusted by leading dental laboratories to create beautiful, durable crowns. Whether your practice focuses on the superior aesthetics of E-Max for front teeth or the robust strength of zirconia for molars, KINTEK supports your commitment to excellence.

Partner with us to ensure your patients receive the best possible care. Contact our experts today to discuss how our solutions can enhance your dental lab's capabilities and help you achieve stunning, natural-looking results.

Visual Guide

Related Products

People Also Ask

- What is titanium disadvantages and advantages? Weighing Performance vs. Cost for Your Project

- What is the main difference between soldering and brazing? Choose the Right Metal Joining Method

- How many types of hardening techniques are there? A Multi-Layered Security Strategy Explained

- What are the strengths of brazing? Achieve Strong, Clean, and Precise Metal Joining

- What are the two methods that can be used to prevent corrosion of a metal? Barrier vs. Sacrificial Protection Explained