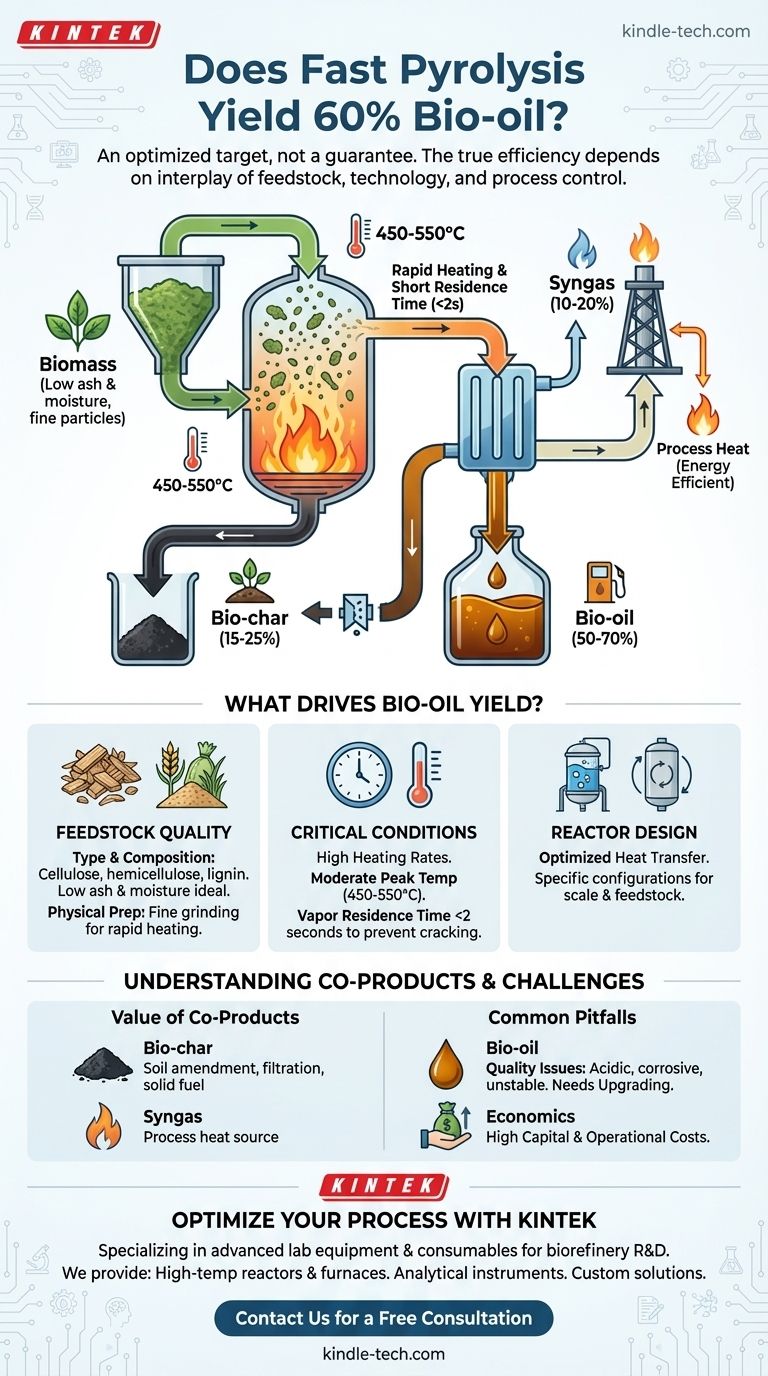

Yes, fast pyrolysis can achieve bio-oil yields of 60% by weight, but this figure represents an optimized, often-cited target rather than a universal guarantee. The final yield is highly dependent on the specific biomass being used, the reactor technology, and precise operating conditions. The process invariably produces a mix of liquid bio-oil, solid bio-char, and non-condensable gases.

The central challenge in fast pyrolysis is not just achieving a high liquid yield, but balancing that yield against the quality of the bio-oil and the value of the co-products. The 60% figure is a useful benchmark, but the true efficiency of a system depends on the interplay of feedstock, technology, and process control.

What Drives Bio-Oil Yield?

Achieving a high percentage of bio-oil is the primary goal of most fast pyrolysis operations. The final distribution between oil, char, and gas is not accidental; it is a direct result of carefully controlled variables.

The Role of Feedstock

The type of biomass used is the foundational factor. Different materials, such as wood, agricultural residues, or grasses, have varying compositions of cellulose, hemicellulose, and lignin.

Materials with low ash and moisture content are ideal for maximizing liquid yields. The physical preparation, such as grinding the biomass into fine particles, is also critical for ensuring rapid and uniform heating.

Critical Process Conditions

Fast pyrolysis is defined by its process conditions. To maximize liquid products, very high heating rates and a moderate peak temperature (typically 450-550°C) are required.

Equally important is the vapor residence time. The hot vapors produced during pyrolysis must be cooled and condensed extremely quickly (in less than 2 seconds) to prevent them from "cracking" into lower-value non-condensable gases.

Reactor Design Matters

There is no single design for a pyrolysis reactor. Different configurations, such as bubbling fluidized bed, circulating fluidized bed, or ablative reactors, have been developed to optimize the heat transfer required for high liquid yields.

The choice of reactor depends on the intended scale of the operation and the specific characteristics of the feedstock being processed.

Understanding the Other Products

Focusing solely on the bio-oil percentage overlooks the complete output of the process. A system that yields 60% bio-oil is also producing 40% of something else, which is rarely wasted.

The Value of Bio-char

The solid co-product, bio-char, typically accounts for 15-25% of the output by weight. It is a stable, carbon-rich material that can be used as a soil amendment, for filtration, or as a solid fuel.

The Utility of Syngas

The gaseous co-product, syngas, typically makes up 10-20% of the output. This mixture of carbon monoxide and hydrogen has a low-to-medium heating value and is almost always combusted on-site to provide the heat needed to run the pyrolysis process itself, making the system more energy-efficient.

Common Pitfalls and Trade-offs

While the technology is promising, a realistic assessment must include its inherent challenges. The pursuit of high yield introduces practical and economic complexities.

Raw Bio-oil Quality

The raw liquid product, often called bio-crude or pyrolysis oil, is not a drop-in replacement for petroleum fuels. It is acidic, corrosive, and chemically unstable.

This necessitates upgrading or stabilization through processes like hydrotreating to make it compatible with existing refinery infrastructure, which adds significant cost and complexity.

Economic Viability

The high capital cost of specialized reactors and the operational expense of preparing feedstock and upgrading the final product are significant hurdles.

The economic success of a facility often depends on creating value from all three output streams—oil, char, and gas—not just the liquid fuel.

Making the Right Choice for Your Goal

Evaluating fast pyrolysis requires defining your primary objective first. The "best" yield is the one that aligns with your specific economic and technical goals.

- If your primary focus is maximizing liquid fuel production: You must select a low-ash, low-moisture feedstock and invest in a reactor designed for extremely rapid heat transfer and vapor quenching.

- If your primary focus is overall system efficiency and value: You should evaluate the local markets for bio-char and design the system to use the syngas effectively, making a slightly lower bio-oil yield potentially more profitable.

Ultimately, viewing fast pyrolysis as a flexible biorefinery process, rather than just an oil producer, is the key to assessing its true potential.

Summary Table:

| Factor | Impact on Bio-oil Yield |

|---|---|

| Feedstock Quality | Low ash & moisture (e.g., wood) maximizes yield |

| Reactor Technology | Fluidized bed designs optimize heat transfer |

| Temperature | 450-550°C for optimal liquid production |

| Vapor Residence Time | <2 seconds prevents cracking into gas |

| Typical Yield Range | 50-70% bio-oil, 15-25% bio-char, 10-20% syngas |

Ready to optimize your pyrolysis process for maximum bio-oil yield?

At KINTEK, we specialize in advanced lab equipment and consumables for biorefinery research and development. Whether you're testing new feedstocks, optimizing reactor conditions, or analyzing bio-oil quality, our precise and reliable solutions help you achieve your goals faster.

We provide:

- High-temperature reactors and furnaces for pyrolysis studies

- Analytical instruments for product characterization

- Custom solutions tailored to your specific biomass and process needs

Contact us today to discuss how KINTEK can support your journey from lab-scale experiments to scalable biorefinery solutions. Let's turn your biomass into valuable products together!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RRDE rotating disk (ring disk) electrode / compatible with PINE, Japanese ALS, Swiss Metrohm glassy carbon platinum

- High Performance Laboratory Freeze Dryer

People Also Ask

- What can sintering affect? Transform Powder into High-Performance Solid Parts

- What are the problems for bio oils utilization? Overcome Key Barriers to Renewable Fuel Adoption

- What is physical vapour deposition used for? Enhance Durability and Performance with PVD Coatings

- What is the instrument used in IR spectroscopy analysis? The Definitive Guide to FTIR Spectrometers

- What are advantages of biomass energy conversion? Turn Waste into Renewable Power & Economic Growth

- Why is high-power ultrasound utilized for MOFs in MMMs? Unlock Superior Gas Separation & Uniform Dispersion

- Why is a laboratory vacuum degassing chamber necessary for bio-based epoxy? Eliminate Voids & Maximize Strength

- What is the function of a continuous stirring device? Master CeO2 Support Preparation and Crystal Uniformity