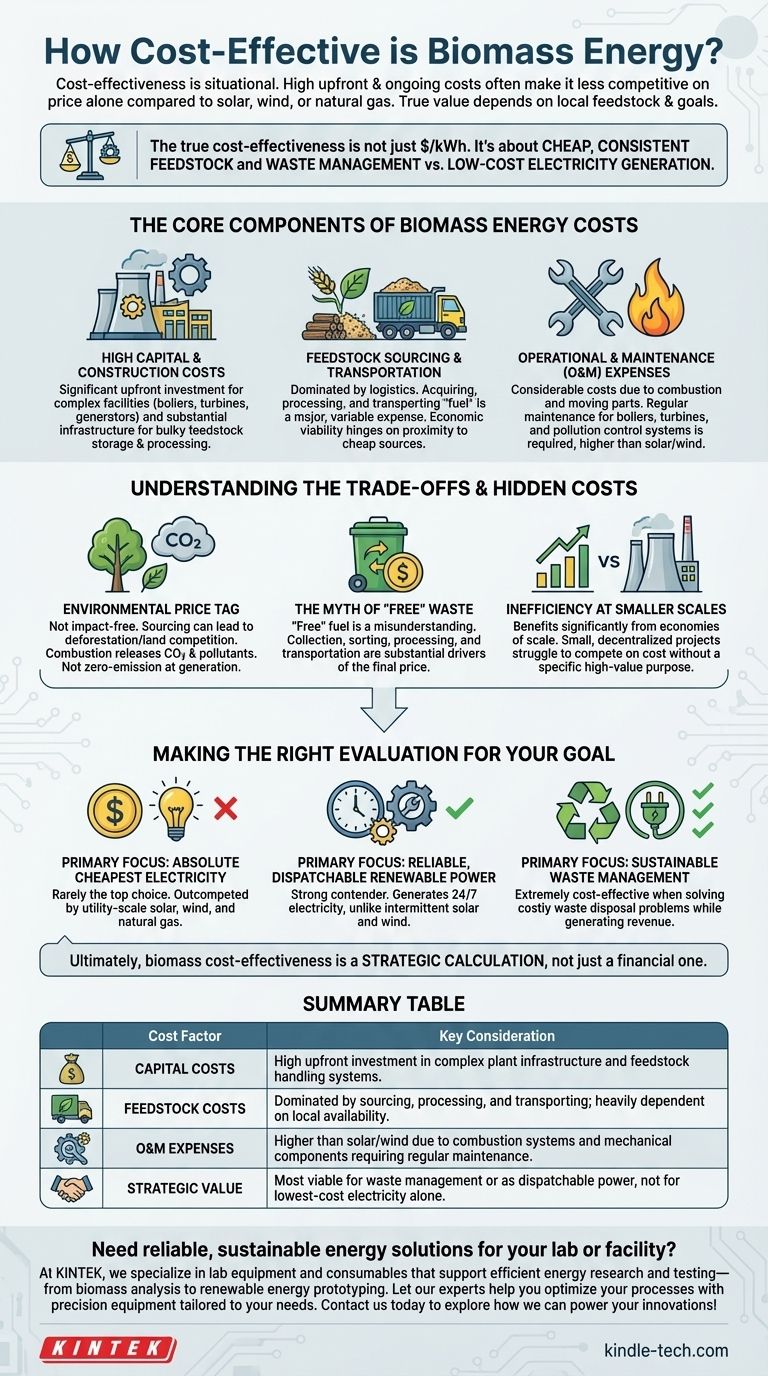

In short, the cost-effectiveness of biomass energy is highly situational and often more complex than other renewables. While it can be an efficient energy source, it frequently involves high upfront construction costs and significant ongoing expenses for fuel and maintenance, making it less competitive on price alone compared to sources like solar, wind, or natural gas in many scenarios.

The true cost-effectiveness of biomass is not measured in dollars per kilowatt-hour alone. It is determined by the local availability of cheap, consistent feedstock and whether the primary goal is waste management or simply low-cost electricity generation.

The Core Components of Biomass Energy Costs

To understand if biomass is a viable option, you must break down its unique cost structure. Unlike solar or wind where the fuel is free, biomass costs are dominated by sourcing and handling physical material.

High Capital & Construction Costs

A biomass power plant is a significant upfront investment. These facilities are mechanically complex, requiring boilers, turbines, and generators similar to traditional power plants.

Furthermore, they require substantial infrastructure for receiving, storing, and processing the bulky feedstock (like wood chips or agricultural waste) before it can even be used for combustion.

Feedstock Sourcing and Transportation

This is the most significant and variable ongoing cost. The "fuel" for biomass—whether it's forestry residue, dedicated energy crops, or municipal waste—is rarely free.

Acquiring, processing, and transporting this material to the power plant is a major logistical and financial challenge. The economic viability of a plant often hinges on its proximity to a cheap, reliable source of feedstock.

Operational and Maintenance (O&M) Expenses

Biomass plants involve combustion and moving parts, leading to considerable O&M costs. Regular maintenance is required for the boilers, turbines, and pollution control systems.

These ongoing expenses are often higher than for solar panels or wind turbines, which have fewer mechanical components and do not require a constant fuel supply chain.

Understanding the Trade-offs and Hidden Costs

A simple price comparison overlooks the strategic advantages and hidden liabilities of biomass energy. Its value is deeply connected to its context.

The Environmental Price Tag

While renewable, biomass is not impact-free. Sourcing feedstock can lead to deforestation or competition for land with food crops if not managed sustainably.

The process of burning organic matter also releases carbon dioxide and other pollutants. While it can be part of a carbon-neutral cycle, it is not a zero-emission source at the point of generation.

The Myth of "Free" Waste

A common argument is that biomass uses "waste" materials, implying the fuel is free. This is a misunderstanding.

Even if the raw material itself is a low-value byproduct, the costs of collection, sorting, processing, and transportation are substantial. These logistical costs are the primary driver of the fuel price.

Inefficiency at Smaller Scales

Biomass power generation benefits significantly from economies of scale. Large-scale plants are far more efficient and cost-effective than smaller installations.

This makes it challenging to deploy small, decentralized biomass projects that can compete on cost without a specific, high-value purpose, such as solving a local waste management issue.

Making the Right Evaluation for Your Goal

To determine if biomass is cost-effective, you must first define your primary objective.

- If your primary focus is the absolute cheapest electricity: Biomass is rarely the top choice and is often outcompeted by utility-scale solar, wind, and natural gas.

- If your primary focus is reliable, dispatchable renewable power: Biomass is a strong contender, as it can generate electricity 24/7, unlike intermittent solar and wind.

- If your primary focus is sustainable waste management: Biomass becomes extremely cost-effective when it solves a costly waste disposal problem (e.g., forestry residue, agricultural waste) while also generating revenue from electricity.

Ultimately, the cost-effectiveness of biomass energy is a strategic calculation, not just a financial one.

Summary Table:

| Cost Factor | Key Consideration |

|---|---|

| Capital Costs | High upfront investment in complex plant infrastructure and feedstock handling systems. |

| Feedstock Costs | Dominated by sourcing, processing, and transporting biomass; heavily dependent on local availability. |

| O&M Expenses | Higher than solar/wind due to combustion systems and mechanical components requiring regular maintenance. |

| Strategic Value | Most viable for waste management or as dispatchable power, not for lowest-cost electricity alone. |

Need reliable, sustainable energy solutions for your lab or facility? At KINTEK, we specialize in lab equipment and consumables that support efficient energy research and testing—from biomass analysis to renewable energy prototyping. Let our experts help you optimize your processes with precision equipment tailored to your needs. Contact us today to explore how we can power your innovations!

Visual Guide

Related Products

- Automatic Laboratory Heat Press Machine

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory High Throughput Tissue Grinding Mill Grinder

- Laboratory Hybrid Tissue Grinding Mill

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the binder in XRF? The Key to Creating Stable, Accurate Sample Pellets

- What maintenance should I do on my furnace? A Proactive Guide to Safety and Reliability

- What is the residue of pyrolysis? Turn Waste into Valuable Biochar, Bio-oil, and Syngas

- What is the FDM extrusion process? A Complete Guide to Layer-by-Layer 3D Printing

- What is a slow pyrolysis? A Guide to Maximizing Biochar Production from Biomass

- Why is a high-precision heating system required for the heat-shock treatment of anaerobic sludge? Maximize Bio-H2 Yield

- What is the process of reactive sputtering? Create High-Performance Compound Films Efficiently

- What is the importance of sintering? Unlock Strength, Density, and Complex Part Production