To choose the correct sieve size, you must first understand the characteristics of your material and the specific goal of your analysis. It's rarely about selecting a single sieve, but rather a stack of sieves with carefully chosen mesh openings that bracket the expected particle size range and provide the level of detail you require.

The core principle is not to find one "perfect" sieve size, but to build a set of sieves—a sieve stack—that creates a particle size distribution profile appropriate for your material and your analytical objectives, often guided by established industry standards.

The Foundation: Understanding Your Material

Before any selection can be made, you must have a deep understanding of the sample you are analyzing. This foundational knowledge dictates every subsequent choice.

Determine the Expected Particle Size Range

First, you need a reasonable estimate of the largest and smallest particles in your sample. This sets the upper and lower bounds for your sieve stack.

If you are working with an unknown material, you may need to perform a preliminary test with a few widely spaced sieves to determine this approximate range.

Consider Particle Shape and Characteristics

The physical nature of the particles impacts how they interact with the sieve mesh. Angular, elongated, or flat particles may not pass through openings as readily as spherical particles of the same mass.

Furthermore, properties like friability (tendency to break apart), static electricity, and moisture content can cause particles to clump or stick to the mesh, leading to inaccurate results.

Defining Your Analytical Goal

The reason you are performing the analysis is the single most important factor in determining how many sieves you need and how they are spaced.

For Quality Control (Go/No-Go Testing)

In many manufacturing and quality control settings, the goal is simply to verify that a material meets a specific threshold. For example, ensuring that less than 5% of a sample is larger than a 1mm screen.

In this scenario, you may only need one or two specification sieves to confirm the material is within its required limits. This is a fast and efficient method for process control.

For Full Particle Size Distribution (PSD)

For research, development, or detailed characterization, the goal is to understand the full spread of particle sizes within the sample. This requires a full sieve stack, typically with 5 to 10 sieves.

The data from this stack is used to create a distribution curve, which provides a comprehensive profile of the material's physical properties.

Building Your Sieve Stack

Once you know your material and your goal, you can select the specific sieves for your stack.

Selecting Your Top and Bottom Sieves

The top sieve should have openings large enough to allow 100% of your sample to pass through, effectively serving to break up agglomerates. The bottom-most component is always a solid pan to collect the finest particles that pass through all the sieves.

The finest sieve in your stack should be small enough to retain some material, but not so fine that an excessive amount of material collects on the pan.

Choosing the Intermediate Sieves

The sieves between the top and bottom are what provide the detail, or resolution, of your analysis. The most common and recommended method is to use a standard progression.

A √2 (square root of two) series is a common standard. In this series, the mesh opening of each successive sieve is 1/√2 (approximately 0.707) times that of the sieve above it. This provides evenly spaced data points when plotted on a logarithmic scale, which is standard for particle size distributions.

Adhering to Industry Standards (ASTM/ISO)

For results to be comparable between different labs, tests must be performed under identical conditions. Many industries have standards, such as ASTM E11 or ISO 3310-1, that specify the exact sieve sizes to be used for a given material.

If you are working in a regulated industry, you must consult the relevant standard to ensure compliance.

Understanding the Trade-offs

Choosing a sieve stack involves balancing competing priorities. Understanding these trade-offs is key to making an informed decision.

Resolution vs. Time and Cost

A stack with more sieves provides a higher-resolution, more detailed distribution curve. However, each additional sieve adds to the purchase cost and the time it takes to perform the analysis and weigh each fraction.

Sample Overloading

Using too much sample material for a given sieve diameter can cause blinding, where the mesh becomes clogged and prevents particles from passing through. This is a primary source of inaccurate results. A larger sieve diameter can accommodate a larger sample volume.

The Limits of Sieving

Dry sieve analysis is generally effective for particles down to about 20 microns. Below this size, forces like static and moisture cause particles to clump together, making it impossible for them to pass through fine meshes.

For these very fine powders, alternative methods like laser diffraction or image analysis are more appropriate.

Making the Right Choice for Your Goal

Your final decision should be a direct reflection of what you need to achieve with your data.

- If your primary focus is quick quality control: You likely only need one or two critical specification sieves to check if your material is above or below a certain size.

- If your primary focus is detailed product characterization: Select a full stack of 5-10 sieves based on a standard progression (like the √2 series) that comprehensively covers your particle range.

- If your primary focus is regulatory compliance or certification: You must use the exact sieve stack specified by the relevant industry standard (e.g., ASTM, ISO) for your specific material or application.

Ultimately, selecting the right sieves is about designing an analysis that yields precise, repeatable, and meaningful data for your specific purpose.

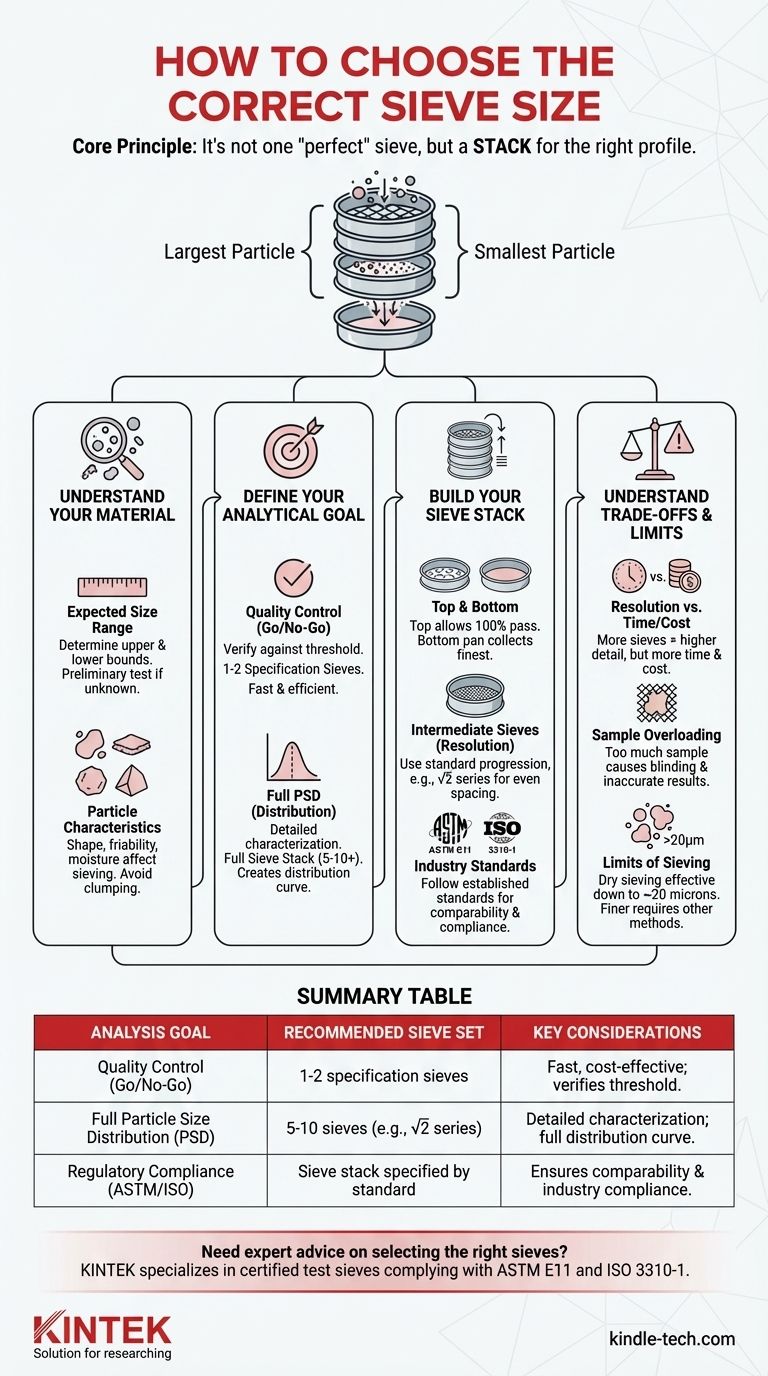

Summary Table:

| Analysis Goal | Recommended Sieve Set | Key Considerations |

|---|---|---|

| Quality Control (Go/No-Go) | 1-2 specification sieves | Fast, cost-effective; verifies material meets a size threshold. |

| Full Particle Size Distribution (PSD) | 5-10 sieves in a √2 progression | Detailed characterization; creates a full distribution curve. |

| Regulatory Compliance (ASTM/ISO) | Sieve stack specified by the standard | Ensures results are comparable and meet industry requirements. |

Need expert advice on selecting the right sieves for your specific application? KINTEK specializes in high-quality lab equipment and consumables, including a full range of certified test sieves that comply with ASTM E11 and ISO 3310-1 standards. Our team can help you build the perfect sieve stack for accurate and repeatable particle analysis. Contact our experts today to optimize your sieving process and achieve precise, meaningful results.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

People Also Ask

- How do high-precision sieving systems benefit zeolite preparation? Maximize Adsorption for Wastewater Treatment

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis

- Why use a vibratory sieve shaker for PET powder? Achieve Precise Particle Size Control for Chemical Research

- Why is powder classification using standard sieves essential for SHS reactions? Unlock Superior Nitriding Results

- Why is a laboratory electromagnetic vibratory sieve shaker used? Optimize Walnut Shell Chemical Pretreatment