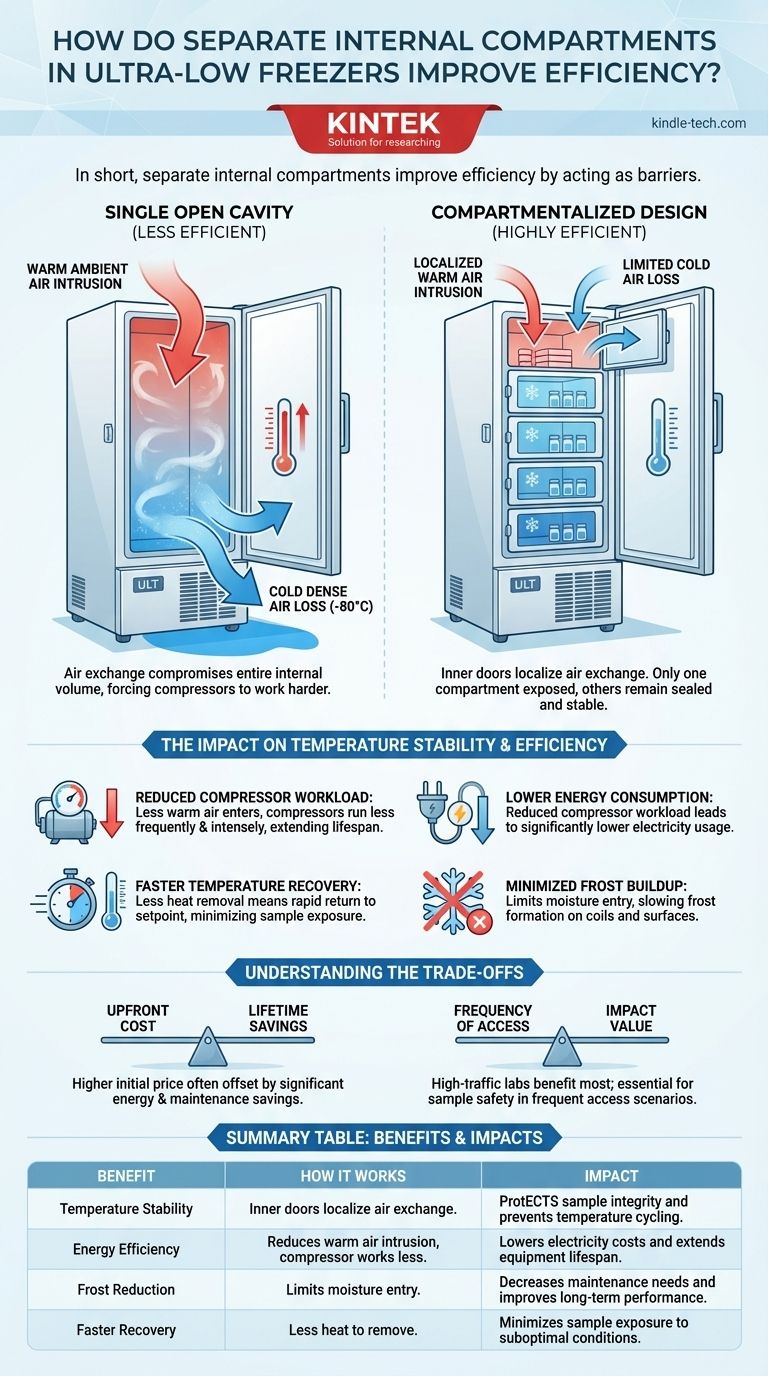

In short, separate internal compartments improve efficiency by acting as barriers. When you open the main freezer door, these inner doors prevent the cold, dense air inside from spilling out and being replaced by warm, moist ambient air. This localizes temperature changes, drastically reducing the energy required for the freezer to return to its ultra-low setpoint.

The core principle is simple: minimizing air exchange is the single most effective way to enhance both temperature stability and energy efficiency in an ultra-low freezer. Compartmentalization achieves this by turning a single large chamber into multiple, independently sealed micro-environments.

The Physics of Cold Loss in a ULT Freezer

To understand the benefit of compartments, we must first examine the problem they solve: warm air intrusion. This is the primary enemy of any ultra-low temperature (ULT) freezer.

The Problem with a Single, Open Cavity

When you open the door of a freezer without inner compartments, a cascade of events occurs. The extremely cold, dense air (e.g., -80°C) is heavier than the warm, ambient air of the lab.

This cold air literally pours out onto the floor, while warmer, more humid air rushes in to replace it. The entire internal volume is now compromised, forcing the refrigeration system to work incredibly hard to remove all that new heat and moisture.

How Compartments Mitigate Air Exchange

Separate inner doors fundamentally change this dynamic. They act as a secondary line of defense.

When the main external door is opened, only the outer surfaces of these sealed inner doors are exposed to the room's air. The vast majority of the freezer's cold air remains trapped within these compartments.

When you open just one inner door to retrieve a sample, the air exchange is confined to that single, small section. The other compartments remain sealed and stable, protecting the valuable samples inside.

The Impact on Temperature Stability

This localized air exchange is critical for temperature stability. Unopened compartments experience a negligible temperature change.

This prevents temperature cycling for samples that are not being accessed, which is crucial for preserving their long-term integrity. The freezer effectively quarantines the impact of every door opening.

Translating Stability into Operational Efficiency

The benefits of improved temperature stability directly translate into measurable gains in operational and energy efficiency.

Reduced Compressor Workload

Because less warm air enters the freezer, the internal temperature rises much less dramatically during an access event.

As a result, the freezer's cascade refrigeration system does not have to run as long or as hard to pull the temperature back down to the setpoint. This reduces wear and tear on the compressors, the heart of the freezer.

Lower Energy Consumption

A direct consequence of reduced compressor workload is lower electricity usage. A freezer that runs its compressors less frequently after door openings will consume significantly less power over its lifespan.

This is why modern, compartmentalized ULTs are often more energy-efficient than older models, even with identical cooling technology.

Faster Temperature Recovery

With less heat to remove, the freezer achieves rapid temperature recovery. A faster "pull-down" time means your samples are returned to their optimal storage temperature more quickly, minimizing their time spent in a compromised state.

This is a key performance metric for labs with frequent freezer access, as it directly impacts sample safety and workflow.

Minimized Frost Buildup

A significant, often overlooked benefit is the reduction of frost. Frost is formed when moisture from the air freezes onto cold surfaces.

By limiting the amount of warm, moist air that enters, compartments drastically reduce the rate of frost formation. Since frost is an insulator that forces the freezer to work harder, minimizing it improves long-term efficiency and reduces the need for manual defrosting.

Understanding the Trade-offs

While highly beneficial, it's important to view compartmentalization within the full context of freezer design.

Upfront Cost vs. Lifetime Savings

Freezers with more robust, well-insulated inner doors may have a higher initial purchase price. However, this cost is often offset over the freezer's lifetime through significant energy savings and reduced maintenance.

Frequency of Access

The value of compartmentalization is directly proportional to how often the freezer is opened. For a high-traffic lab, it is an essential feature. For a unit used purely for long-term, untouched archiving, its impact on daily energy use is lower, but its role in protecting against accidental, prolonged door openings remains critical.

Quality of Inner Doors

Not all compartments are created equal. Look for inner doors that latch securely and have gaskets to create a proper seal. A poorly sealed inner door offers a fraction of the benefit of a well-engineered one.

Making the Right Choice for Your Goal

Ultimately, this feature is about mitigating risk and managing operational costs.

- If your primary focus is frequent access and high throughput: A freezer with multiple, well-sealed inner compartments is non-negotiable for ensuring both sample safety and energy efficiency.

- If your primary focus is long-term preservation of critical samples: The superior temperature stability offered by compartmentalization provides the best possible protection against temperature excursions, safeguarding your most valuable assets.

- If your primary focus is minimizing your total cost of ownership: Look beyond the sticker price and factor in the long-term energy savings that a well-compartmentalized freezer provides.

Choosing a freezer with effective internal compartments is a foundational decision for protecting both your scientific work and your operational budget.

Summary Table:

| Benefit | How It Works | Impact |

|---|---|---|

| Temperature Stability | Inner doors localize air exchange to one compartment, keeping others stable. | Protects sample integrity and prevents temperature cycling. |

| Energy Efficiency | Reduces warm air intrusion, so the compressor works less to recover temperature. | Lowers electricity costs and extends equipment lifespan. |

| Frost Reduction | Limits moisture entry, slowing frost buildup on coils and surfaces. | Decreases maintenance needs and improves long-term performance. |

| Faster Recovery | Less heat to remove means the freezer returns to setpoint more quickly. | Minimizes sample exposure to suboptimal conditions. |

Optimize your lab's sample storage and energy usage with KINTEK. Our ultra-low freezers are engineered with advanced compartmentalization to ensure maximum temperature stability, reduce operational costs, and protect your valuable research. Whether you need reliable equipment for high-throughput labs or long-term archiving, KINTEK delivers solutions tailored to your laboratory needs. Contact us today to find the perfect freezer for your workflow!

Visual Guide

Related Products

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 28L Compact Upright Ultra Low Temperature Freezer for Laboratory

- 108L Vertical Ultra Low Temperature ULT Freezer

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 708L Ultra Low Temperature Freezer High Performance Laboratory Freezer

People Also Ask

- How are advancements in compressor technology and refrigerant fluids improving ULT freezers? Boost Efficiency & Cut Costs

- What temperature ranges are typically associated with ultra-low temperature freezers? Preserve Samples from -40°C to -86°C

- What is the temperature control capability of ultra-low freezers? Precise Stability Down to -86°C

- How does fast temperature recovery benefit ultra-low freezers? Protect Sample Integrity and Lab Efficiency

- What are the key features to look for in an ultra-low temperature freezer for mRNA vaccine storage? Essential Features for Absolute Vaccine Integrity