At their core, ultra-low temperature (ULT) freezers achieve extreme cold not with a single, powerful cooling system, but with two distinct refrigeration circuits working in tandem. This specialized architecture, known as a cascade refrigeration system, allows the freezer to overcome the physical limitations of a standard single-compressor design and reliably maintain temperatures as low as -86°C.

A ULT freezer is essentially two freezers built into one cabinet. The first system's only job is to cool down the second system, enabling that second circuit to absorb heat from the storage chamber and reach ultra-low temperatures.

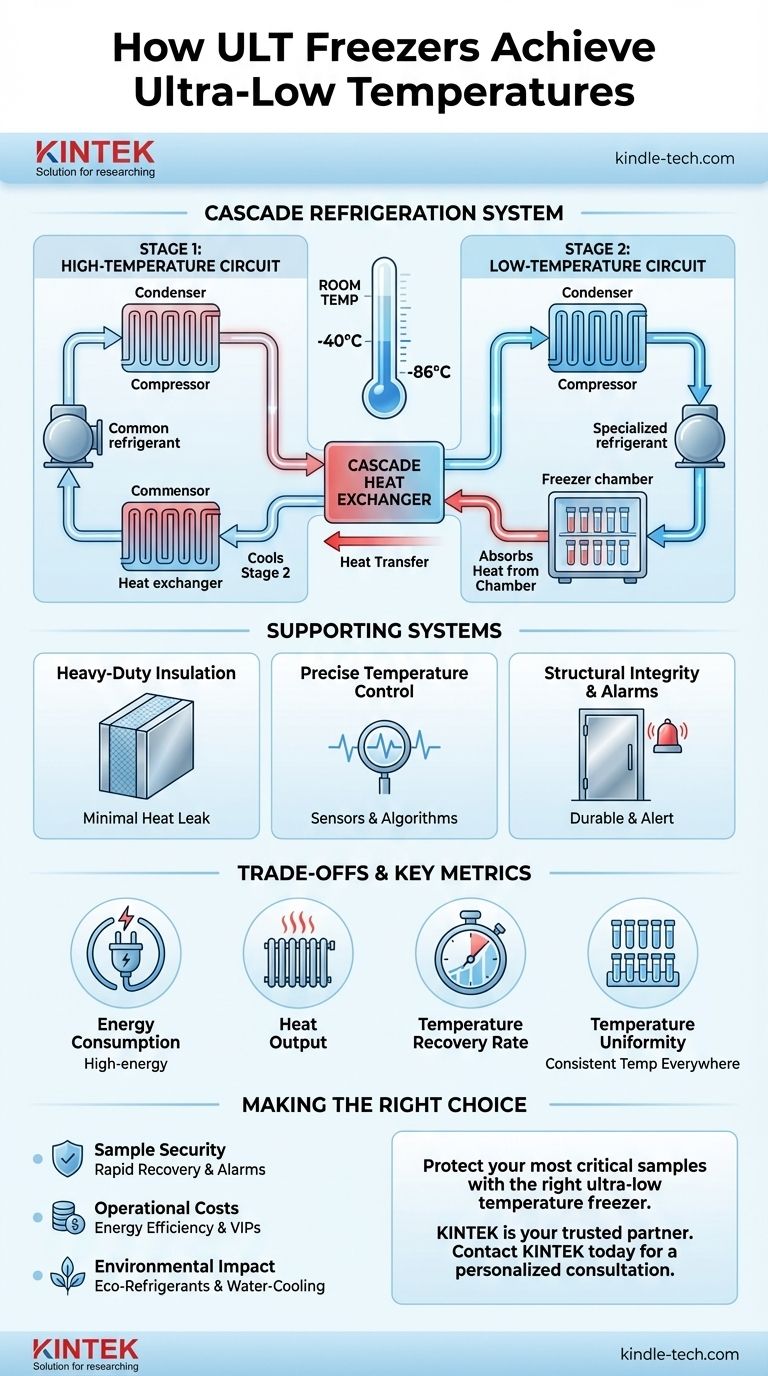

The Core Technology: The Cascade Refrigeration System

To understand how a ULT freezer works, it's best to visualize it as a two-stage process where heat is passed up a "temperature ladder" until it can be released into the room.

Stage Zero: How a Standard Freezer Works

A normal freezer uses a single vapor-compression circuit. A liquid refrigerant absorbs heat inside the cabinet and evaporates into a gas. This gas is then compressed, which makes it very hot, and pumped to coils on the outside, where it releases its heat into the room and condenses back into a liquid to repeat the cycle.

This single-stage process is highly effective but has a thermodynamic limit, typically around -40°C.

The First Stage: The High-Temperature Circuit

A ULT freezer’s first stage operates much like a standard freezer. It uses a common refrigerant to cool a specialized heat exchanger.

Its critical purpose is not to cool the sample chamber directly. Instead, it is dedicated solely to absorbing the heat released by the second refrigeration circuit.

The Second Stage: The Low-Temperature Circuit

The second stage is where the ultra-low temperatures are generated. This circuit uses a specialized refrigerant with a much lower boiling point, allowing it to absorb heat even at -80°C.

This circuit pulls heat from the freezer's interior chamber, turning its refrigerant into a gas. However, it cannot release this heat directly into the room because its condensation point is too low.

Putting It Together: The Cascade

The two systems meet at a component called a cascade heat exchanger. Here, the hot, gaseous refrigerant from the low-temperature (second) stage is cooled by the cold refrigerant from the high-temperature (first) stage.

This allows the second-stage refrigerant to turn back into a liquid, enabling it to continue pulling heat from the chamber. The heat it transferred is then carried away by the first stage and exhausted into the lab, completing the cascade.

The Supporting Systems That Ensure Performance

Achieving the temperature is only half the battle. Maintaining it reliably requires a robust supporting infrastructure.

Heavy-Duty Insulation

ULT freezers use thick, high-performance insulation in the walls and door. This minimizes the amount of ambient heat that "leaks" into the cabinet, which reduces the workload on the compressors and improves energy efficiency.

Precise Temperature Control

Modern ULTs use a network of sensors and sophisticated control algorithms. The system constantly monitors the internal temperature and makes micro-adjustments to the compressors' activity to hold the setpoint with extreme precision.

Structural Integrity and Alarms

Features like stainless steel interiors provide durability and are easy to clean. Tightly sealed doors with heated pressure release valves prevent both cold air loss and the formation of a vacuum that could seal the door shut.

Audible and visual alarms are critical safety features that immediately alert personnel to temperature deviations, ensuring sample integrity is never compromised.

Understanding the Trade-offs and Key Metrics

While effective, this technology comes with inherent trade-offs that are important to understand.

Energy Consumption

Running two independent refrigeration systems is highly energy-intensive. A ULT freezer is often one of the most power-hungry devices in a laboratory, contributing significantly to operational costs.

Heat Output

All the heat removed from the freezer's interior, plus waste heat generated by the compressors themselves, is exhausted directly into the surrounding room. This can place a substantial load on a building's HVAC system.

Temperature Recovery Rate

This is a critical performance metric. After a door is opened, the time it takes for the freezer to return to its setpoint is the recovery rate. A slow recovery can expose sensitive samples to damaging temperature fluctuations.

Temperature Uniformity

Uniformity refers to the temperature consistency throughout the entire storage chamber. Poor uniformity can create "hot spots" where samples are not maintained at the correct temperature, even if the central sensor reads correctly.

Making the Right Choice for Your Goal

When selecting or operating a ULT freezer, your specific priorities should guide your evaluation.

- If your primary focus is irreplaceable sample security: Prioritize models with rapid temperature recovery rates, proven temperature uniformity, and robust, multi-layered alarm systems.

- If your primary focus is managing operational costs: Look for units with advanced vacuum insulation panels (VIPs), energy-efficient compressors, and features that minimize frost build-up.

- If your primary focus is the impact on your lab's environment: Consider models with lower heat output, those that use more environmentally friendly refrigerants, or units that connect to building water-cooling systems.

Understanding the principles behind the technology empowers you to select and operate the right equipment to protect your critical work.

Summary Table:

| Key Component | Function |

|---|---|

| Cascade Refrigeration System | Two-stage process using two separate circuits to overcome thermodynamic limits. |

| High-Temperature Circuit (1st Stage) | Cools the second stage's refrigerant; acts like a standard freezer. |

| Low-Temperature Circuit (2nd Stage) | Uses a specialized refrigerant to absorb heat from the storage chamber, achieving ultra-low temps. |

| Cascade Heat Exchanger | Where the two stages meet; the 2nd stage releases heat to the 1st stage. |

| Heavy-Duty Insulation | Minimizes heat leakage, improving efficiency and temperature stability. |

Protect your most critical samples with the right ultra-low temperature freezer.

Understanding the complex technology behind ULT freezers is the first step. Selecting the ideal model for your lab's specific needs—whether prioritizing sample security, energy efficiency, or environmental impact—is the next.

KINTEK is your trusted partner for laboratory equipment. We specialize in providing reliable ULT freezers and expert guidance to ensure your valuable research samples are stored securely and efficiently. Let our specialists help you evaluate your requirements and find the perfect solution for your laboratory.

Contact KINTEK today for a personalized consultation and discover how we can support your lab's success.

Visual Guide

Related Products

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 608L Essential Laboratory Ultra Low Temperature Freezer For Critical Sample Preservation

- 708L Ultra Low Temperature Freezer High Performance Laboratory Freezer

- 28L Compact Upright Ultra Low Temperature Freezer for Laboratory

People Also Ask

- How are advancements in compressor technology and refrigerant fluids improving ULT freezers? Boost Efficiency & Cut Costs

- What is the temperature control capability of ultra-low freezers? Precise Stability Down to -86°C

- What are the recommendations for storing mRNA vaccines in ultra-low temperature freezers? Ensure Absolute Stability at -80°C

- What temperature ranges are typically associated with ultra-low temperature freezers? Preserve Samples from -40°C to -86°C

- How is temperature controlled in ultra low temperature freezers? A Guide to Stable -80°C Storage