To check if a diamond is a CVD lab-grown diamond, you must rely on third-party verification, not visual inspection. The most reliable method is to examine the diamond's official grading report or certificate from a reputable gemological lab, which will explicitly state its origin as "Laboratory-Grown" and may specify the "CVD" method. Many of these diamonds also have a microscopic laser inscription on their edge that matches the report number and confirms their lab-grown status.

Because CVD diamonds are chemically, physically, and optically identical to natural diamonds, they cannot be distinguished by sight alone. Verification is a matter of documentation and disclosure, not observation.

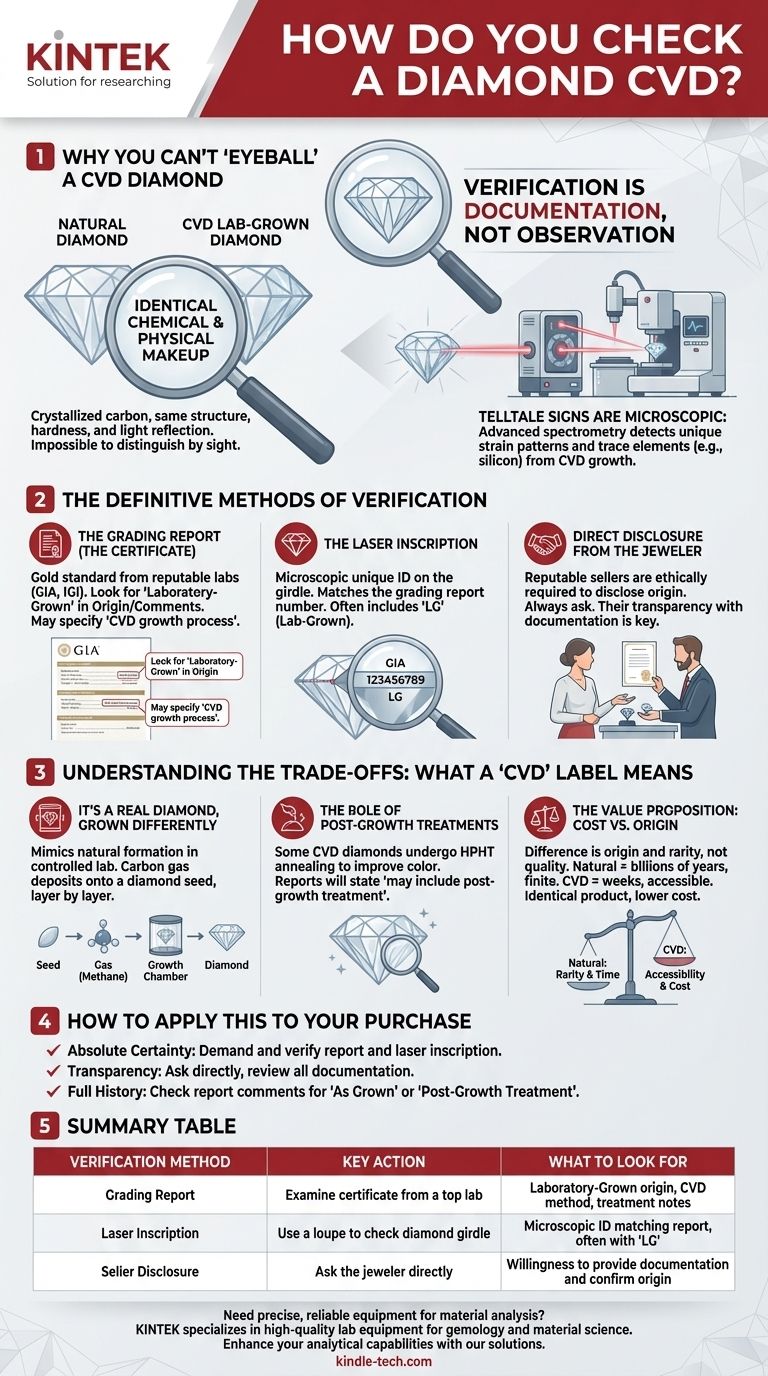

Why You Can't "Eyeball" a CVD Diamond

The fundamental challenge in identifying a CVD diamond is that it is a real diamond. The distinction lies in its origin, not its essential properties.

Identical Chemical and Physical Makeup

Both natural and CVD diamonds are crystallized carbon. They have the same atomic structure, the same hardness, and the same way of reflecting light, making them appear identical to the naked eye and even to a trained jeweler using a standard loupe.

Telltale Signs Are Microscopic

Laboratories use advanced spectrometric equipment to identify a diamond's origin. They look for microscopic clues that are impossible for a consumer or retailer to detect without specialized tools.

These clues can include specific strain patterns visible under high magnification or the presence of minute trace elements, such as silicon, which can be residuals from the CVD growth process.

The Definitive Methods of Verification

Since visual inspection is unreliable, you must depend on the systems of traceability and disclosure established by the gemological industry.

The Grading Report (The Certificate)

This is your single most important tool. A report from a respected laboratory like the GIA (Gemological Institute of America) or IGI (International Gemological Institute) is the gold standard for verification.

Look for explicit language in the "Origin" or "Comments" section. It will clearly state "Laboratory-Grown". The report may further specify that the diamond was created by the Chemical Vapor Deposition (CVD) growth process.

The Laser Inscription

Reputable labs laser-inscribe a unique identification number onto the diamond's girdle (its thin outer edge). This number is microscopic and can be viewed with a jeweler's loupe.

This inscription matches the number on the grading report, creating a direct physical link between the diamond and its documentation. Often, the inscription will also include letters like "LG" to denote "Lab-Grown."

Direct Disclosure from the Jeweler

A reputable jeweler or dealer is ethically and often legally required to disclose whether a diamond is natural or lab-grown. Always ask directly. Their willingness to provide a corresponding grading report is a key indicator of their transparency and trustworthiness.

Understanding the Trade-offs: What a "CVD" Label Means

Knowing a diamond's origin is crucial because it directly impacts its market value and informs your purchase.

It's a Real Diamond, Grown Differently

The CVD process mimics natural diamond formation, but in a highly controlled, accelerated environment. It starts with a small diamond "seed" placed in a vacuum chamber, which is then filled with carbon-rich gas (like methane). When energized, these gases break down, and carbon atoms deposit onto the seed, growing a diamond layer by layer.

The Role of Post-Growth Treatments

Some CVD diamonds undergo treatments after they are grown, most commonly HPHT (High Pressure/High Temperature) annealing, to improve their color. A grading report will disclose this. Look for phrases like "may include post-growth treatment" to understand the diamond's full history.

The Value Proposition: Cost vs. Origin

The primary difference between a CVD and a natural diamond is its origin and rarity. Natural diamonds are a finite resource formed over billions of years, which accounts for their higher price. CVD diamonds can be produced in weeks, making them a more accessible and affordable option. Their value proposition is based on providing the identical physical product at a lower cost.

How to Apply This to Your Purchase

Your verification strategy depends on your primary goal.

- If your primary focus is absolute certainty: You must demand the original grading report from a top-tier lab (like GIA or IGI) and personally verify that the laser inscription on the diamond matches the report number.

- If your primary focus is transparency from a seller: Ask directly if the diamond is lab-grown and request to see all accompanying documentation before any money changes hands.

- If your primary focus is understanding the diamond's full history: Carefully read the comments on the certificate to see if it is "As Grown" or if it has undergone any "post-growth treatment."

Ultimately, verification empowers you to buy with confidence, fully understanding the nature and value of the diamond you have chosen.

Summary Table:

| Verification Method | Key Action | What to Look For |

|---|---|---|

| Grading Report | Examine the certificate from a top lab (e.g., GIA, IGI). | "Laboratory-Grown" origin, "CVD" method, post-growth treatment notes. |

| Laser Inscription | Use a loupe to check the diamond's girdle. | Microscopic ID number matching the report, often with "LG" for Lab-Grown. |

| Seller Disclosure | Ask the jeweler directly for full transparency. | Willingness to provide documentation and confirm the diamond's origin. |

Need precise, reliable equipment for material analysis? The process of verifying a CVD diamond relies on advanced laboratory technology. At KINTEK, we specialize in high-quality lab equipment and consumables that support the precise analysis and research needed in gemology and material science. Whether you're a research lab, a gemological institute, or a quality control facility, our solutions can enhance your analytical capabilities. Contact our experts today to find the right tools for your laboratory's needs!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory CVD Boron Doped Diamond Materials

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What is the role of the HF-CVD system in preparing BDD electrodes? Scalable Solutions for Boron-Doped Diamond Production

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth

- How are reactants introduced into the reaction chamber during a CVD process? Mastering Precursor Delivery Systems

- How does a Hot Filament Chemical Vapor Deposition (HFCVD) reactor function? Expert Guide to Diamond Film Fabrication

- What machine is used to make lab-grown diamonds? Discover the HPHT & CVD Technologies