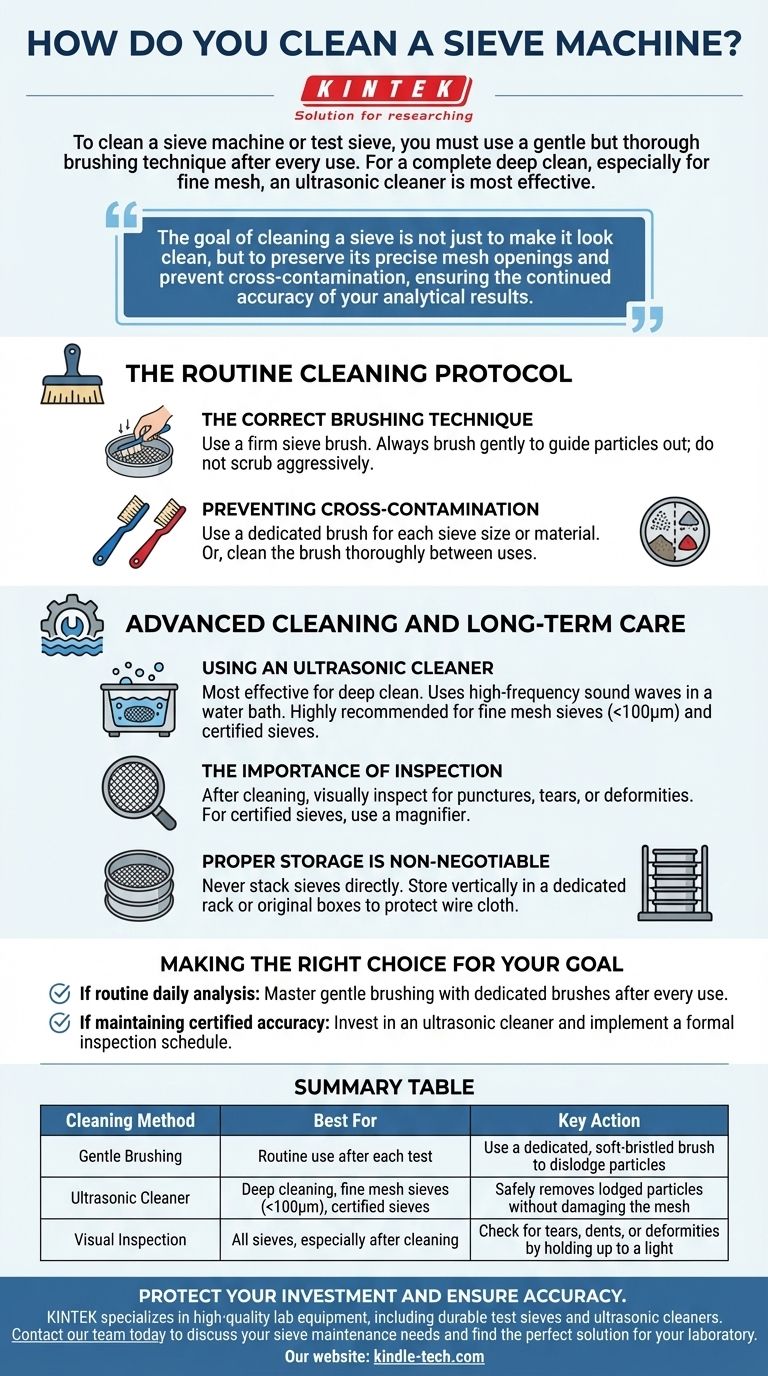

To clean a sieve machine or test sieve, you must use a gentle but thorough brushing technique after every use to recover retained particles and prevent them from lodging in the mesh. For a complete and deep clean, especially for fine mesh or certified sieves, an ultrasonic cleaner is the most effective method.

The goal of cleaning a sieve is not just to make it look clean, but to preserve its precise mesh openings and prevent cross-contamination, ensuring the continued accuracy of your analytical results.

The Routine Cleaning Protocol

Proper cleaning after each test is the foundation of sieve maintenance. This prevents particle buildup, known as blinding, and ensures the sieve is ready for the next analysis.

The Correct Brushing Technique

Your primary tool is a sieve brush. The bristles should be firm enough to dislodge particles but not so stiff that they damage the delicate mesh.

Always brush gently. The goal is to guide particles out of the mesh openings, not to scrub them aggressively, which can stretch or tear the wire cloth.

Preventing Cross-Contamination

Use a dedicated brush for each sieve size or for specific material types. This is the single best way to prevent fine particles from a previous sample from contaminating a new one.

If a dedicated brush isn't feasible, ensure the brush is thoroughly cleaned between uses.

Handling Lodged Particles

If gentle brushing does not remove a stubborn lodged particle, do not resort to using a sharp, pointed tool. This will almost certainly damage the mesh.

Instead, a slightly firmer brushing action or tapping the sieve frame may dislodge it. For persistent blinding, the sieve requires a deep clean.

Advanced Cleaning and Long-Term Care

For precision work or when routine cleaning is insufficient, more advanced methods are required. This is also part of a larger maintenance strategy to maximize the sieve's lifespan and reliability.

Using an Ultrasonic Cleaner

An ultrasonic cleaner is the most effective and safest way to perform a deep clean. It uses high-frequency sound waves in a water bath to gently and completely dislodge fine particles from the mesh without causing physical damage.

This method is highly recommended for fine mesh sieves (below 100μm) or any sieve used for certification or critical quality control, as it restores the effective open area.

The Importance of Inspection

After cleaning, and before storage, conduct a quick visual inspection. Hold the sieve up to a light to check for obvious punctures, tears, or deformities in the mesh.

For certified sieves, periodic inspection with a magnifier is necessary to identify any dents, sagging, or broken wires that would compromise its accuracy.

Proper Storage is Non-Negotiable

Never stack sieves directly on top of one another. The weight and movement can easily dent, sag, or puncture the mesh of the sieve below.

Always store sieves vertically in a dedicated rack or in their original boxes. This protects the critical wire cloth from contact and accidental damage.

Making the Right Choice for Your Goal

- If your primary focus is routine daily analysis: Master the gentle brushing technique with dedicated brushes after every single use to ensure consistency.

- If your primary focus is maintaining certified accuracy: Invest in an ultrasonic cleaner for periodic deep cleaning and implement a formal inspection schedule.

Properly cleaned and maintained sieves are not just tools; they are precise measurement instruments that produce reliable data.

Summary Table:

| Cleaning Method | Best For | Key Action |

|---|---|---|

| Gentle Brushing | Routine use after each test | Use a dedicated, soft-bristled brush to dislodge particles |

| Ultrasonic Cleaner | Deep cleaning, fine mesh sieves (<100μm), certified sieves | Safely removes lodged particles without damaging the mesh |

| Visual Inspection | All sieves, especially after cleaning | Check for tears, dents, or deformities by holding up to a light |

Protect your investment and ensure the accuracy of your particle analysis. Proper sieve maintenance is critical for reliable data. KINTEK specializes in high-quality lab equipment, including durable test sieves and ultrasonic cleaners designed for precision cleaning. Let our experts help you choose the right tools to extend the life of your sieves and maintain your quality standards.

Contact our team today to discuss your sieve maintenance needs and find the perfect solution for your laboratory.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Single Horizontal Jar Mill

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What are the factors affecting sieving performance and efficiency? Optimize Your Particle Separation Process

- Why is a precision vibrating sieve shaker essential for metal leaching research? Optimize Your Particle Size Analysis

- How are vibratory sieve shakers and standard sieves utilized to analyze the effects of biomass torrefaction? Optimize Grindability

- What are the specifications for test sieves? A Guide to ASTM & ISO Standards for Accurate Particle Analysis

- What is the primary function of a mechanical sieve shaker for biomass analysis? Optimize Particle Size Distribution