The most effective method for cleaning ball milling equipment is a multi-step process that combines physical removal of bulk material, solvent washing to dissolve fine residue, and thorough drying. For applications requiring extreme purity, a final "sacrificial" grinding run with an inert material is performed to scrub the surfaces of any remaining trace contaminants from the grinding jar and media.

The goal of cleaning a ball mill is not just to make it look clean, but to systematically eliminate cross-contamination. The integrity of your next sample depends entirely on how well you remove the previous one.

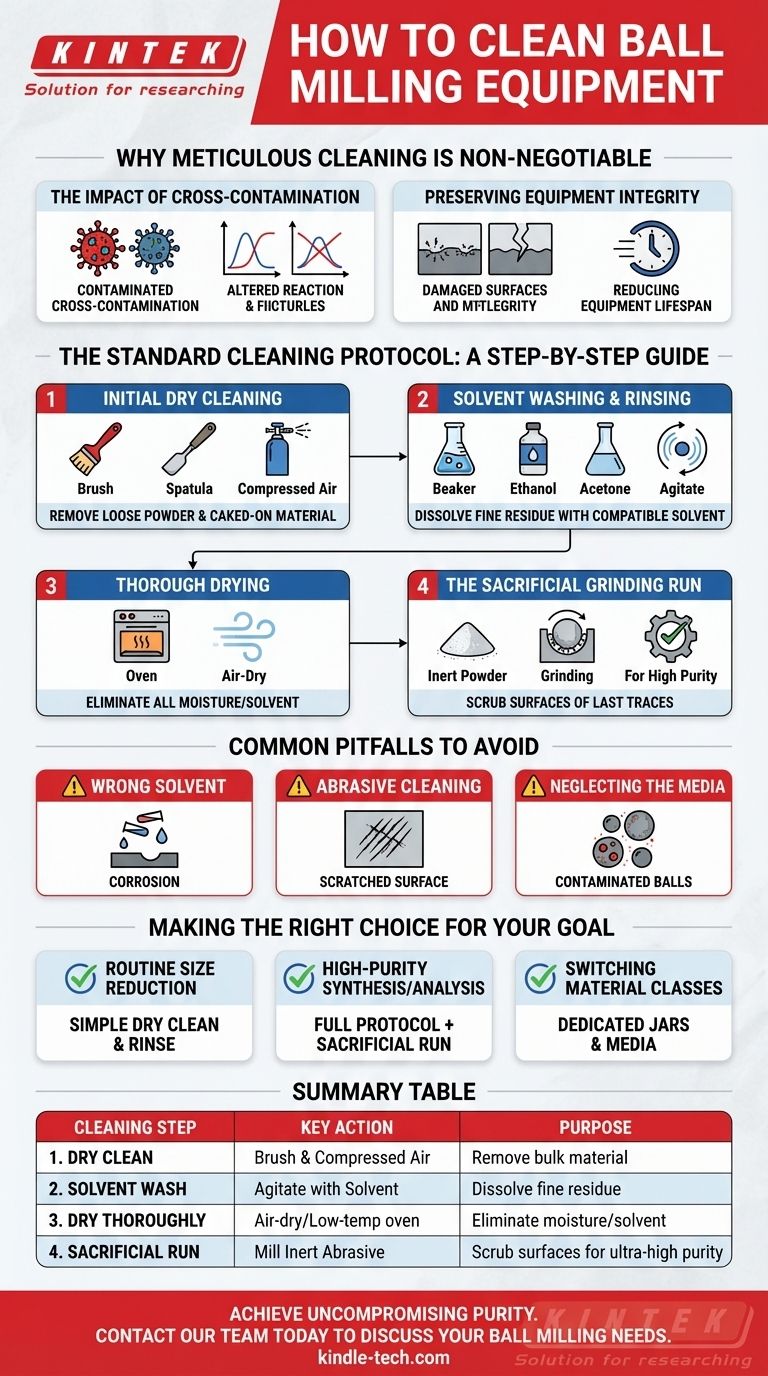

Why Meticulous Cleaning is Non-Negotiable

In materials science, pharmaceuticals, and chemical synthesis, even minute amounts of contamination can drastically alter the results of an experiment or the properties of a final product. A poorly cleaned mill is an uncontrolled variable.

The Impact of Cross-Contamination

Contamination introduces impurities that can inhibit chemical reactions, alter the physical characteristics of a new material, or skew analytical measurements. This leads to unreliable data and non-repeatable processes.

Preserving Equipment Integrity

Proper cleaning methods also preserve the lifespan of your grinding jars and media. Using incorrect solvents or overly abrasive techniques can damage the surfaces, making future cleaning more difficult and introducing contaminants from the equipment itself.

The Standard Cleaning Protocol: A Step-by-Step Guide

Follow this systematic process to ensure a thoroughly cleaned system, ready for the next batch. Always wear appropriate personal protective equipment (PPE), including gloves and safety glasses.

Step 1: Initial Dry Cleaning

The first objective is to remove all loose powder and cake-on material. Use a soft brush, a plastic or rubber spatula, and compressed air (in a well-ventilated area or fume hood) to physically dislodge and remove the bulk of the material from the jar and grinding media.

Step 2: Solvent Washing and Rinsing

Choose a solvent that effectively dissolves the material you just milled but does not damage the jar or media. Common choices include deionized water, ethanol, isopropanol, or acetone.

Add the solvent to the jar along with the grinding media, seal it, and agitate it—either by hand or by running it in the mill for a few minutes. Dispose of the contaminated solvent properly, then rinse thoroughly with fresh solvent.

Step 3: Thorough Drying

All components must be completely dry before reuse. Residual moisture or solvent can ruin your next batch. You can allow the components to air-dry or place them in a low-temperature oven, ensuring the temperature is safe for your specific jar material (especially for polymers like PTFE or nylon).

Step 4: The Sacrificial Grinding Run

For high-purity applications, this final step is critical. Add an inert, inexpensive abrasive powder like silica sand or quartz to the jar and run a short milling cycle. This powder will "scrub" the surfaces, trapping the last traces of the previous material. Discard the sacrificial powder afterward.

Common Pitfalls to Avoid

Even a good protocol can fail if common mistakes are made. Awareness of these pitfalls is key to achieving consistent, contamination-free results.

Pitfall 1: Using the Wrong Solvent

An ineffective solvent will fail to remove fine residue, leaving behind a thin film of contamination. Conversely, an overly aggressive solvent can damage polymer jars or cause corrosion in steel jars. Always verify solvent compatibility.

Pitfall 2: Abrasive Physical Cleaning

Never use metal wire brushes or scrapers on your jars or media, especially on softer materials like stainless steel or polymers. Scratches create microscopic crevices where material can become trapped, making future cleaning nearly impossible.

Pitfall 3: Neglecting the Grinding Media

The grinding media (the balls) have a massive collective surface area. They must be cleaned with the same diligence as the jar. It is often easiest to clean them inside the jar during the solvent wash stage.

Making the Right Choice for Your Goal

Your cleaning regimen should match the sensitivity of your work.

- If your primary focus is routine size reduction of the same material: A simple dry clean and solvent rinse between batches may be sufficient.

- If your primary focus is high-purity synthesis or analytical sampling: The full protocol, including a sacrificial grinding run, is essential to guarantee sample purity.

- If you are switching between vastly different material classes (e.g., a metal oxide to an organic compound): The safest approach is to use completely separate, dedicated jars and grinding media for each class.

Ultimately, a disciplined cleaning process is the foundation of reliable and repeatable ball milling.

Summary Table:

| Cleaning Step | Key Action | Purpose |

|---|---|---|

| 1. Dry Clean | Brush & use compressed air | Remove bulk powder & caked-on material |

| 2. Solvent Wash | Agitate with compatible solvent | Dissolve fine residue from jar & media |

| 3. Dry Thoroughly | Air-dry or use low-temperature oven | Eliminate moisture/solvent for next batch |

| 4. Sacrificial Run | Mill inert abrasive (e.g., sand) | Scrub surfaces for ultra-high purity applications |

Achieve Uncompromising Purity in Your Lab

Contamination-free ball milling is critical for reliable research and production. KINTEK specializes in high-quality lab equipment and consumables, including durable grinding jars and media designed for easy, effective cleaning. Our experts can help you select the right equipment for your specific materials and purity requirements.

Ensure the integrity of every sample. Contact our team today to discuss your ball milling needs and discover how KINTEK can support your laboratory's success.

Visual Guide

Related Products

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- Where are ball mills used? Essential Grinding Solutions for Mining, Cement, and Pharma

- What role do high-energy ball mills play in MPEA powders? Achieve Nanoscale Precision in Mechanical Alloying

- What role do high-energy ball mills and ultrasonic crushing equipment play in nano-scale biochar preparation? Explore!

- Why is a planetary ball mill preferred over manual grinding for LiZr2(PO4)3? Achieve High-Conductivity Powder Synthesis

- What is the primary function of a ball mill in the preparation of composite electrodes? Unlock Ion Transport Channels

- What role does high-energy ball milling equipment play in ODS steels? Powering Precision Mechanical Alloying

- What is the primary function of high-energy ball milling equipment? Unlock Nano-Scale Tungsten Alloy Synthesis

- What role does a planetary ball mill play in the preparation of LGVO powders? Precision Refinement for Aerosol Deposition