At its core, cleaning ball milling media involves a multi-stage process of mechanical removal, solvent washing, and thorough drying. The specific solvent and method depend entirely on the material you just milled and the material of your grinding media. For most common applications, a sequence of scraping, washing with a solvent like acetone or ethanol, sonicating, rinsing, and oven drying is the standard protocol.

The most significant risk in ball milling is not mechanical failure, but invisible cross-contamination. An inadequate cleaning process can invalidate your results by introducing impurities from a previous batch, making a rigorous and well-chosen cleaning protocol an essential part of the milling process itself.

The Principle: Why Meticulous Cleaning is Non-Negotiable

Ball milling is a process of intense, high-energy impacts. During milling, microscopic particles of the sample material become embedded and smeared onto the surfaces of the milling balls and the jar.

The Impact of Cross-Contamination

If not removed, this residue will be incorporated into your next batch. Even trace amounts can act as an unwanted dopant, catalyst, or structural defect, altering the chemical and physical properties of your new material.

For research in fields like pharmaceuticals, battery materials, or advanced ceramics, this level of contamination can render an entire experiment invalid.

More Than Just Purity

Proper cleaning also provides an opportunity to inspect your media. Regular handling allows you to spot chips, cracks, or significant wear, which can reduce milling efficiency and introduce contaminants from the media itself.

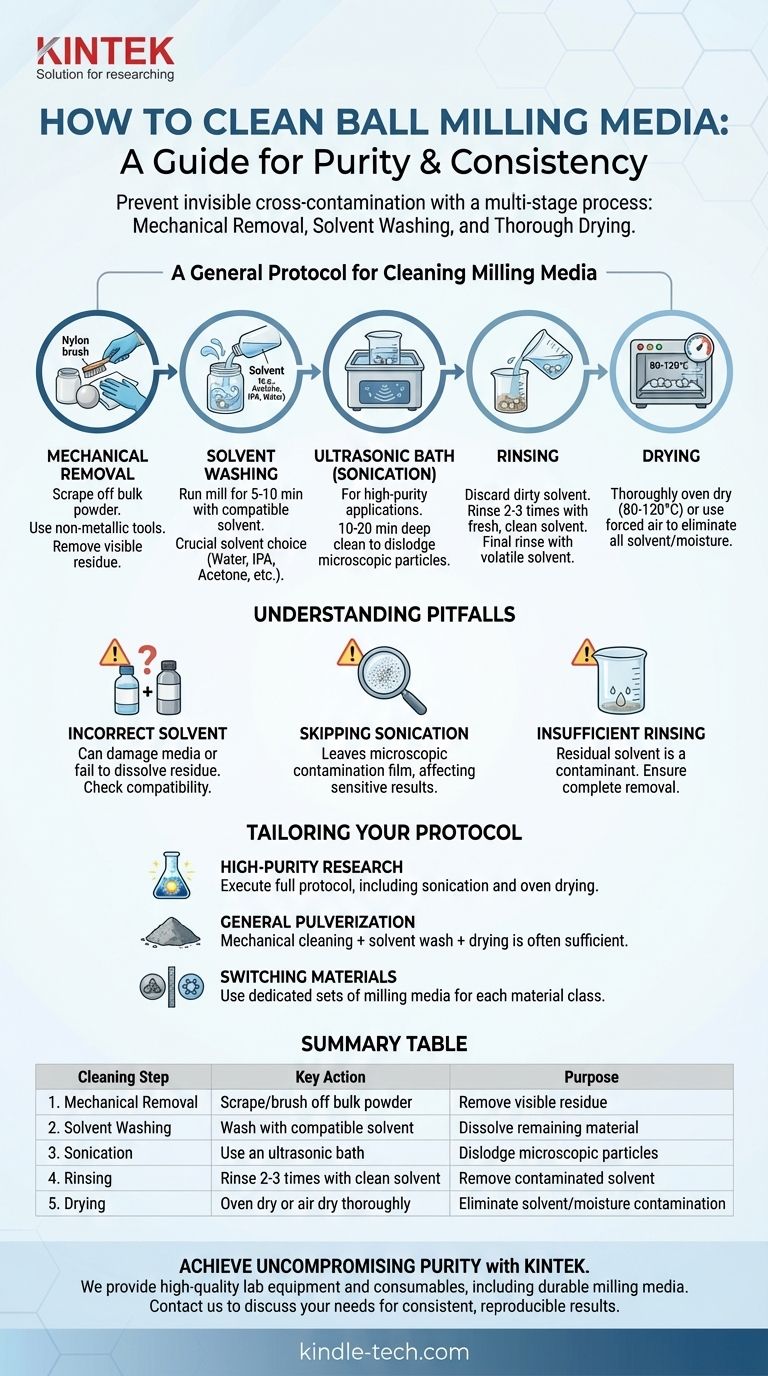

A General Protocol for Cleaning Milling Media

This step-by-step guide can be adapted for most situations. The critical decision is the choice of solvent in Step 2.

Step 1: Mechanical Removal

First, remove as much of the bulk powder as possible. Use a nylon brush, rubber spatula, or dry cloth to wipe the media and the inside of the jar. For stubborn, caked-on material, a plastic or wooden scraper can be effective. Avoid using metal tools that could scratch or damage the media.

Step 2: Solvent Washing

The goal is to dissolve the remaining residue. The choice of solvent is crucial.

- For water-soluble salts and ceramics, start with deionized water.

- For most organic compounds and polymers, isopropyl alcohol (IPA) or ethanol are excellent starting points.

- For polymers, greases, or oils, acetone is a powerful and effective solvent.

- For non-polar organics, you may need a stronger solvent like toluene or hexane. Use these only in a well-ventilated fume hood.

Fill the milling jar about one-third full with the chosen solvent and the media. Run the mill at a low speed for 5-10 minutes. This "blank" run uses mechanical action to help the solvent clean the surfaces.

Step 3: Ultrasonic Bath (Sonication)

For high-purity applications, this step is essential. After the initial solvent wash, transfer the media and solvent into a beaker and place it in an ultrasonic bath for 10-20 minutes.

The high-frequency sound waves create microscopic cavitation bubbles that dislodge fine particles from the tiny pits and pores on the media's surface, providing a much deeper clean than washing alone.

Step 4: Rinsing

After the primary wash, you must rinse away the contaminated solvent. Discard the dirty solvent and perform two to three subsequent rinses with fresh, clean solvent. A final rinse with a high-volatility solvent like clean IPA or acetone can help speed up drying.

Step 5: Drying

Residual solvent or moisture is also a contaminant. Media must be thoroughly dried before storage or reuse.

- Oven Drying: The most reliable method. Place the clean media in a glass beaker or on a tray in an oven at 80-120°C for at least an hour. Ensure your media (e.g., some plastics) can handle the temperature.

- Air Drying: If an oven is unavailable, spread the media on a clean, lint-free cloth inside a fume hood to air dry.

- Forced Air: A stream of compressed air or nitrogen can be used to speed up the drying process.

Understanding the Trade-offs and Pitfalls

Mistakes in cleaning are common and can have significant consequences.

Pitfall 1: Incorrect Solvent Choice

Using a solvent that does not dissolve your material is the most common error. It will simply suspend the particles, which will then resettle on the media as the solvent evaporates. Worse, using a solvent that chemically attacks your media (e.g., strong acid on stainless steel) will damage your equipment and contaminate future batches. Always verify solvent-media compatibility.

- Zirconia/Alumina Media: Very chemically inert. Safe with most solvents and mild acids/bases.

- Stainless Steel Media: Robust, but avoid strong acids and chloride-containing solutions, which cause corrosion. Dry immediately and thoroughly to prevent rust.

- Tungsten Carbide Media: Extremely hard and dense, but can be corroded by oxidizing acids.

Pitfall 2: Skipping Sonication

For routine grinding, a thorough wash may be sufficient. But for sensitive applications like nanoparticle synthesis or pharmaceutical formulation, skipping sonication leaves behind a microscopic film of contaminants that can skew your results.

Pitfall 3: Insufficient Rinsing

Leaving behind residual cleaning solvent is just another form of contamination. If you wash with acetone, but your next reaction is sensitive to it, any leftover acetone can inhibit or alter the process.

Making the Right Choice for Your Goal

Tailor your cleaning protocol to the required purity level of your work.

- If your primary focus is high-purity research (e.g., catalysts, quantum dots): You must execute the full protocol, including sonication, multiple rinses with high-purity solvent, and oven drying.

- If your primary focus is general material pulverization or alloying: A thorough mechanical cleaning followed by a solvent wash (e.g., with ethanol) and complete drying is often sufficient.

- If you are switching between chemically distinct materials (e.g., from a metal oxide to an organic polymer): Your best strategy is to maintain separate, dedicated sets of milling media for each material class to completely eliminate the risk of contamination.

A consistent and appropriate cleaning protocol is not a peripheral task; it is fundamental to producing reliable and reproducible results.

Summary Table:

| Cleaning Step | Key Action | Purpose |

|---|---|---|

| 1. Mechanical Removal | Scrape/brush off bulk powder | Remove visible residue |

| 2. Solvent Washing | Wash with compatible solvent (e.g., IPA, acetone) | Dissolve remaining material |

| 3. Sonication | Use an ultrasonic bath | Dislodge microscopic particles |

| 4. Rinsing | Rinse 2-3 times with clean solvent | Remove contaminated solvent |

| 5. Drying | Oven dry or air dry thoroughly | Eliminate solvent/moisture contamination |

Achieve Uncompromising Purity in Your Milling Processes

Cross-contamination from improperly cleaned media can invalidate your research and waste valuable materials. KINTEK understands the critical need for precision and reliability in laboratory workflows. We specialize in providing high-quality lab equipment and consumables, including durable milling media and cleaning supplies, to support your demanding applications—from pharmaceuticals to advanced ceramics.

Let us help you maintain the integrity of your work. Our experts can assist you in selecting the right media and establishing robust cleaning protocols tailored to your specific materials.

Contact KINTEK today to discuss your lab's needs and ensure your milling results are consistently pure and reproducible.

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- What are the effects of ball milling? A Deep Dive into Mechanical Alloying and Material Transformation

- What are the primary technical tasks of a planetary ball mill for Na3SbS4 synthesis? Optimize Your Electrolyte Production

- Why is it necessary to maintain an argon atmosphere for Cu-Zr-Ti ball milling? Ensure High-Purity Amorphous Alloys

- Why is the control of milling time in a planetary ball mill essential? Mastering Ultra-Fine WC-10Co Quality Control

- What is the primary function of a ball mill during the preparation of TiB2-SiC composite powders? Master Mixing Quality

- Why is the planetary ball mill the core equipment for UHTCs? Master High-Energy Material Refinement

- What is the role of a high-energy ball mill and zirconia grinding balls in NASICON electrolyte powder preparation?

- What is the function of a planetary ball milling system? Prepare CrFeAlTi Composite Powders for Ceramic Coatings