Preventing vacuum leaks is not about a single action, but a systematic process. True prevention is rooted in a disciplined maintenance program focused on the integrity of sealing surfaces, regular system inspections, and continuous performance monitoring. While quick fixes exist, they are not a substitute for proper component care and a proactive mindset.

The core principle of vacuum leak prevention is that leaks are rarely sudden, catastrophic failures. Instead, they are the result of gradual degradation. Therefore, preventing them requires a shift from reactive repairs to a proactive maintenance strategy that preserves the integrity of every seal and connection in the system.

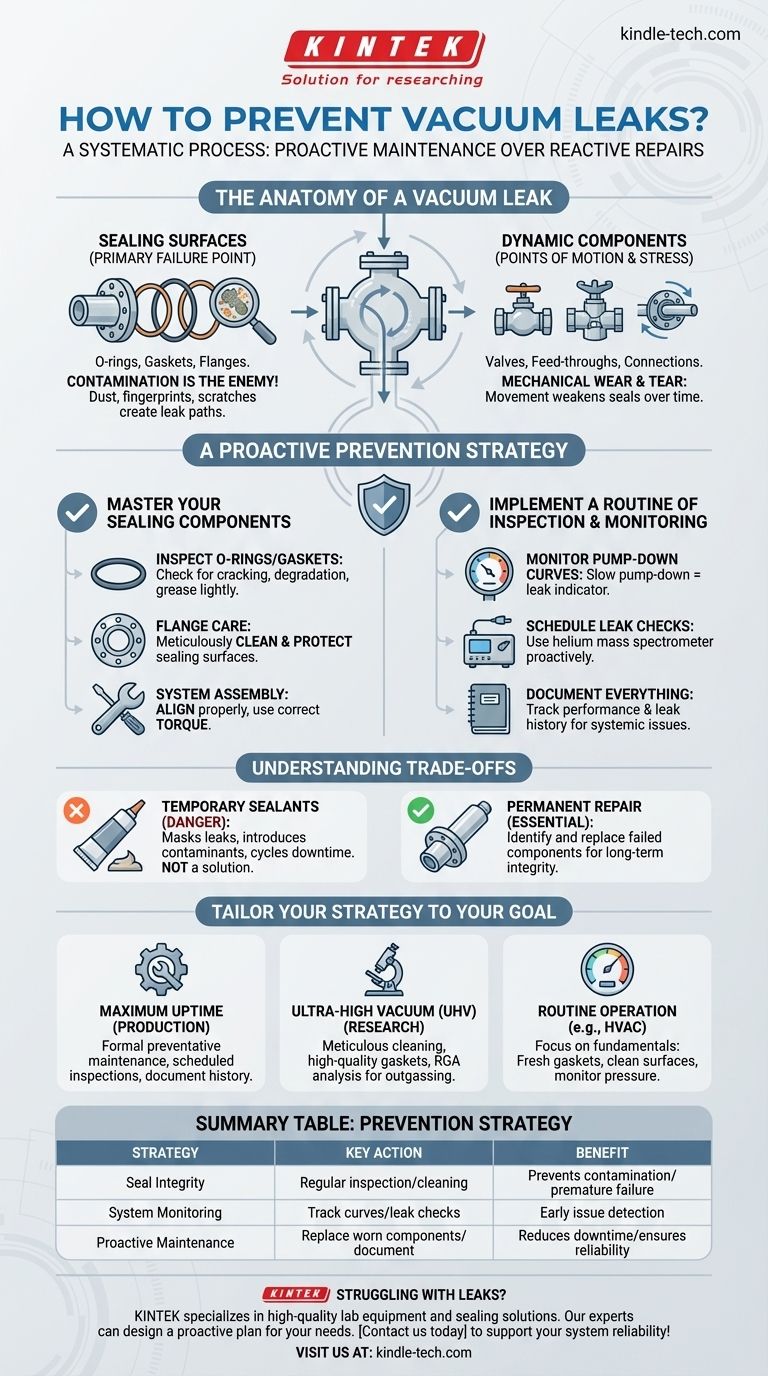

The Anatomy of a Vacuum Leak

To prevent leaks, you must first understand where they originate. Leaks are almost always a failure at a point of connection or sealing, not a flaw in a solid piece of material.

Sealing Surfaces: The Primary Failure Point

The vast majority of leaks occur where two components meet. This includes O-rings, gaskets, and metal-on-metal flanges.

Contamination is the enemy of a good seal. Even a microscopic particle of dust, a fingerprint, or a scratch on a flange can create a path for air to enter the system.

Dynamic Components: Points of Motion and Stress

Any part of the system that moves or passes through the vacuum wall is a potential weak point. This includes valves, rotational feed-throughs, and electrical connections.

These components are subject to mechanical wear and tear over their lifecycle, making them prime candidates for developing leaks over time.

A Proactive Prevention Strategy

A robust strategy is built on disciplined maintenance rather than emergency repairs. This involves care, inspection, and monitoring.

Master Your Sealing Components

The health of your seals determines the health of your vacuum.

- O-Rings and Gaskets: Regularly inspect O-rings for signs of flattening, cracking, or degradation. Ensure they are lightly and correctly greased (if required for your application) and never over-tightened, which can cause them to fail prematurely.

- Flange Surfaces: Always keep flange surfaces meticulously clean and protected from scratches. A smooth, clean surface is essential for creating an impermeable seal.

- System Assembly: When assembling the system, ensure all connections are properly aligned and tightened to the correct torque specification. Misalignment puts uneven stress on seals, creating a leak path.

Implement a Routine of Inspection and Monitoring

You cannot prevent what you cannot see. Regular checks are critical for catching problems early.

- Monitor Pump-Down Curves: During initial evacuation, watch your vacuum gauge. A system that is slow to pump down or cannot reach its expected base pressure is a clear indicator of a leak.

- Schedule Leak Checks: Do not wait for a problem to occur. Periodically perform a leak check on the entire system using a dedicated instrument, such as a helium mass spectrometer leak detector. This can identify minuscule leaks long before they impact your process.

- Document Everything: Keep a log of system performance and maintenance. Tracking the location of previous leaks is invaluable, as these areas often indicate a systemic stress point that may require attention again.

Understanding the Trade-offs: Temporary vs. Permanent Solutions

In an emergency, a quick fix can seem appealing. However, it's crucial to understand the significant downsides.

The Danger of Temporary Sealants

Applying external sealing compounds or "vacuum mud" over a suspected leak is a temporary patch, not a solution. It should only be used in an emergency to keep a process running until a proper repair can be scheduled.

These compounds can mask the true source of the leak, making it much harder to find and fix permanently later. They can also introduce contaminants into your system.

Why Permanent Repair is Non-Negotiable

A permanent repair involves identifying the failed component—the specific O-ring, gasket, or flange—and replacing or properly cleaning it.

Relying on temporary fixes creates a cycle of recurring problems and system downtime. Replacing temporary sealing compounds with permanent repairs must be a core part of any preventive maintenance program.

How to Apply This to Your Goal

Your prevention strategy should be tailored to your system's requirements and your operational goals.

- If your primary focus is maximum uptime in production: Implement a formal preventive maintenance program with scheduled inspections, O-ring replacement cycles, and documentation of all leak history.

- If your primary focus is achieving ultra-high vacuum (UHV) for research: Your process must be flawless. Focus on meticulous component cleaning, use of high-quality metal gaskets, and routine system analysis with a residual gas analyzer (RGA) to detect even the smallest outgassing or leak sources.

- If your primary focus is routine operation (e.g., HVAC service): Prioritize the fundamentals. Always use fresh gaskets, ensure all connection surfaces are clean before sealing, and monitor system pressure closely during evacuation to confirm integrity.

Ultimately, maintaining a leak-free vacuum system is about adopting a mindset of proactive discipline.

Summary Table:

| Prevention Strategy | Key Action | Benefit |

|---|---|---|

| Seal Integrity | Regular O-ring/gasket inspection and proper flange cleaning | Prevents contamination and premature seal failure |

| System Monitoring | Track pump-down curves and schedule periodic leak checks | Early detection of issues before they impact processes |

| Proactive Maintenance | Replace worn components and document all repairs | Reduces unplanned downtime and ensures long-term reliability |

Struggling with vacuum leaks or planning a new system? KINTEK specializes in high-quality lab equipment and consumables, including vacuum components and sealing solutions. Our experts can help you design a proactive maintenance plan tailored to your laboratory's specific needs, ensuring maximum uptime and process integrity. Contact us today to discuss how we can support your vacuum system reliability!

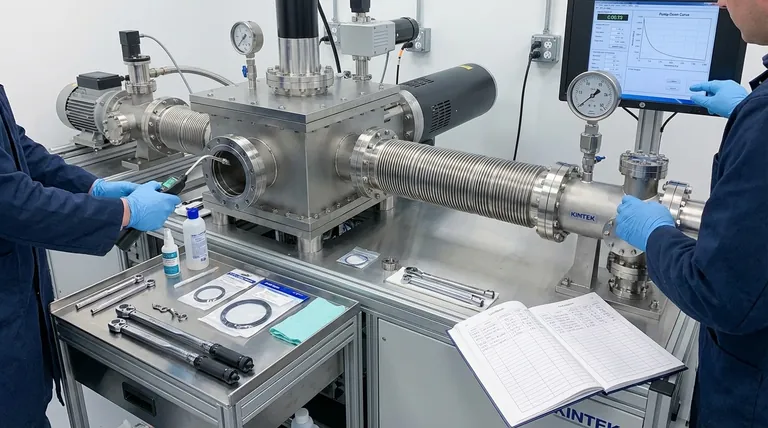

Visual Guide

Related Products

- Vacuum Bellows for Efficient Connection and Stable Vacuum in High-Performance Systems

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Vacuum Cold Mounting Machine for Sample Preparation

People Also Ask

- Which method of heat transfer occur in a vacuum? Unlocking the Power of Thermal Radiation

- What are the benefits of annealing metal? Enhance Ductility and Relieve Internal Stresses

- What is the primary function of a vacuum drying oven during MPCF pretreatment? Optimize Fiber Quality Today

- What is the function of a vacuum drying oven in the preparation of succinimide anion-based ionic liquids?

- What is a sintering furnace for powder metallurgy? Transform Powder into High-Strength Parts

- What is the temperature of a calcination furnace? Precise Control from 800°C to 1300°C

- What features are required in high-temperature furnace equipment for the large-scale pyrolysis of nano-packaging particles?

- What is thin film deposition thermal evaporation? A Simple Guide to High-Vacuum Coating