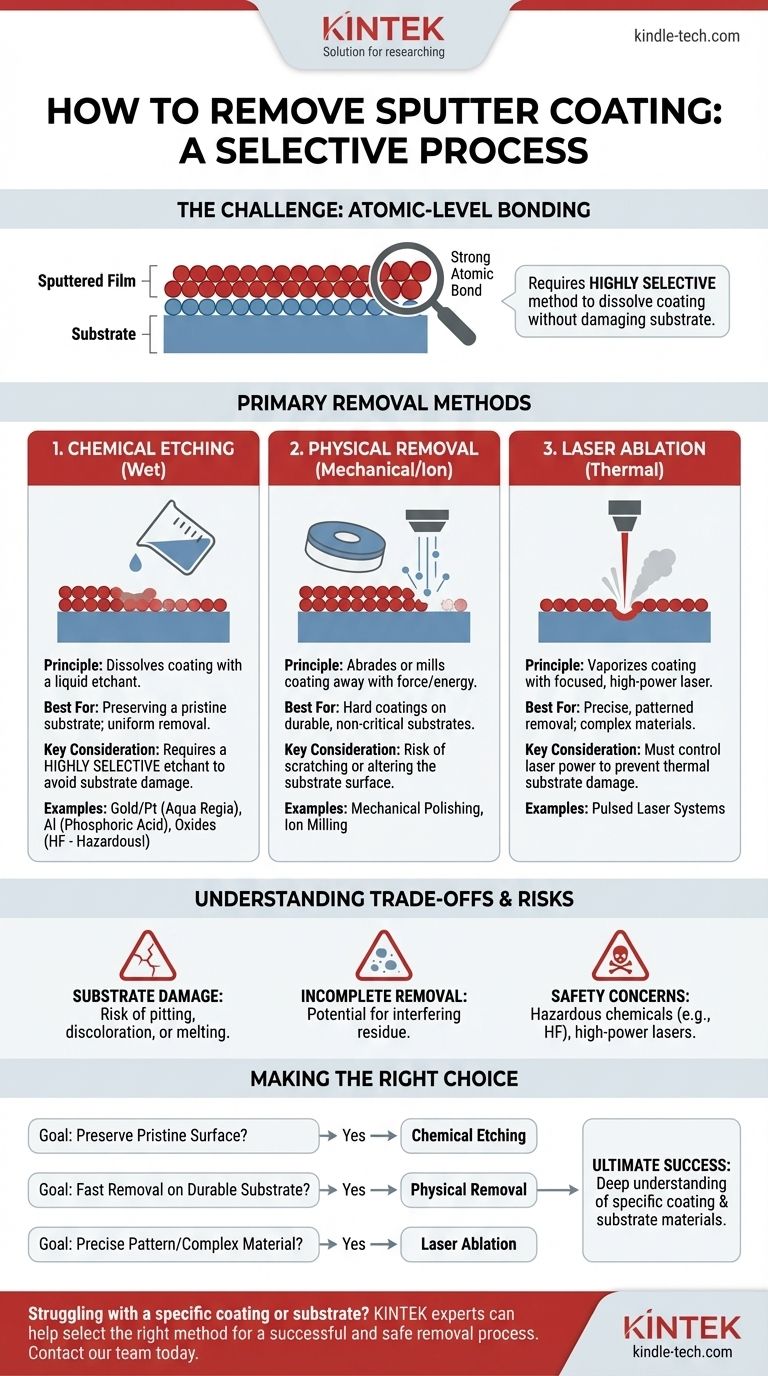

To remove a sputter coating, you must use a method that attacks the coating material while leaving the underlying substrate unharmed. The most common techniques are chemical etching, physical abrasion, or laser ablation. The ideal choice depends entirely on the specific materials of both the thin film and the substrate it is deposited on.

The core challenge of removing a sputter coating lies in its atomic-level bond with the substrate. Unlike paint, it cannot simply be peeled off. A successful removal requires a highly selective method that aggressively dissolves or ablates the coating without damaging the surface underneath.

Why Sputter Coating Removal is a Challenge

Sputter coating, as a physical vapor deposition (PVD) process, creates an extremely thin and durable film. Understanding the nature of this film is key to understanding the difficulty of its removal.

The Tenacious Atomic Bond

The sputtering process uses high-energy ions to bombard a target, ejecting atoms that then deposit onto your substrate. These atoms arrive with significant energy, forming a dense, well-adhered film that is atomically bonded to the surface. This creates a much stronger bond than simple mechanical adhesion.

The Need for Material Selectivity

Because the coating is so thin and well-bonded, the removal process must be highly selective. This means the chosen method must react strongly with the coating material (e.g., gold, titanium, aluminum oxide) but have little to no effect on the substrate material (e.g., silicon, glass, polymer).

Primary Methods for Sputter Coat Removal

There are three primary approaches to stripping a sputtered film. Each operates on a different principle and is suited for different material combinations.

Method 1: Chemical Etching

This technique, also known as wet etching, uses a liquid chemical solution (an etchant) to dissolve the sputtered film.

This is often the preferred method when a suitable etchant exists, as it can remove the entire film uniformly without introducing mechanical stress to the substrate. Success depends entirely on finding an etchant that rapidly dissolves the coating while being inert to the substrate.

Common examples include:

- Gold or Platinum films: Often removed with Aqua Regia (a mixture of nitric acid and hydrochloric acid).

- Aluminum films: Can be etched with solutions containing phosphoric acid or sodium hydroxide.

- Oxide films (e.g., SiO₂, ITO): Often require aggressive acids like hydrofluoric acid (HF), which is extremely hazardous and requires specialized handling.

Method 2: Physical Removal

These methods use mechanical force or energy to remove the coating from the surface.

Mechanical polishing or lapping involves using fine abrasive slurries to physically grind the coating away. This method is straightforward but is only suitable for hard, durable substrates where minor surface scratches or changes in flatness are acceptable.

Ion milling is essentially reverse sputtering. A broad-beam ion source is aimed at the coated surface, and the high-energy ions physically knock atoms off the film, slowly eroding it away. It offers high control but is a very slow process.

Method 3: Laser Ablation

This method uses a highly focused, high-power laser beam to deliver intense energy to the coating.

The energy rapidly heats and vaporizes the thin film material, effectively "blasting" it off the substrate. Laser ablation is extremely precise and can be used to selectively remove the coating in specific patterns. However, care must be taken to avoid thermal damage or melting of the underlying substrate.

Understanding the Trade-offs and Risks

Choosing the wrong method can irreversibly damage your part. It is critical to consider the potential downsides before proceeding.

Risk of Substrate Damage

This is the single greatest risk. An overly aggressive chemical etchant can pit, discolor, or completely dissolve the substrate. Likewise, mechanical polishing can introduce scratches and sub-surface damage, while excessive laser power can cause cracking or melting.

Incomplete Removal and Residue

Sometimes a removal process can leave behind small islands of the coating material or a thin layer of chemical residue. This can interfere with any subsequent analysis, processing, or re-coating steps.

Critical Safety Concerns

Chemical etching, in particular, often involves highly corrosive and toxic acids. Hydrofluoric acid (HF), for example, can cause severe, life-threatening burns. Always work in a certified fume hood with appropriate personal protective equipment (PPE) and have proper disposal protocols in place.

Making the Right Choice for Your Goal

Your optimal removal strategy is dictated by your materials and your objective.

- If your primary focus is preserving the substrate's pristine surface: Chemical etching with a highly selective etchant is often the best choice, provided one exists for your material combination.

- If you are removing a hard coating from a durable, non-critical substrate: Mechanical polishing can be a fast and effective physical method for complete removal.

- If you require precise, patterned removal or are working with complex materials: Laser ablation or focused ion beam milling offers the highest degree of control, but at a higher cost and complexity.

Ultimately, a successful removal process is defined by a deep understanding of your specific coating and substrate materials.

Summary Table:

| Method | Principle | Best For | Key Consideration |

|---|---|---|---|

| Chemical Etching | Dissolves coating with a liquid etchant. | Preserving a pristine substrate; uniform removal. | Requires a highly selective etchant to avoid substrate damage. |

| Physical Removal | Abrades or mills coating away with force/energy. | Hard coatings on durable, non-critical substrates. | Risk of scratching or altering the substrate surface. |

| Laser Ablation | Vaporizes coating with a focused, high-power laser. | Precise, patterned removal; complex materials. | Must control laser power to prevent thermal substrate damage. |

Struggling with a specific coating or substrate? Removing a sputter coating requires precision and expertise to avoid costly damage to your valuable samples and components. At KINTEK, we specialize in lab equipment and consumables, and our experts understand the intricacies of thin film processes. We can help you select the right method or equipment for your specific material combination, ensuring a successful and safe removal process. Contact our team today for a consultation and let us help you protect your substrates and achieve your project goals. Reach out via our contact form

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for PTFE Stirring Bar Recovery Rod

- Lab Internal Rubber Mixer Rubber Kneader Machine for Mixing and Kneading

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What is the function of adding trace CO2 in MW-SWP CVD? Control Planar Graphene Growth and Suppress Nanowalls

- What is the purpose of adding a boron source in CVD diamond growth? Master P-Type Semiconductor Conductivity

- What is a thin film technology? The Atomic-Scale Process Powering Modern Electronics

- What is the general process of sputtering for creating thin films? Master Precision PVD Coating Techniques

- What is the chemical composition of pyrolysis oil? A Complex Emulsion of Water and Oxygenated Organics

- What is the temperature range for CVD? It's Not a Single Number—It's Dictated by Your Materials

- Why is high-speed wafer rotation necessary for vertical CVD? Master Flow Engineering for 4H-SiC Thin Films

- Why is a high-precision MFC essential for CVD systems? Ensure Superior Membrane Separation Performance