In essence, a gold sputter coater works by creating a powerful plasma in a vacuum. This plasma, typically made of argon gas, is used to bombard a solid gold target with energetic ions. The force of these collisions physically knocks or "sputters" individual gold atoms off the target, which then travel through the vacuum and deposit onto your sample, building up a uniform, ultra-thin metallic film.

The process is not a chemical reaction but a physical one based on momentum transfer. It uses high-energy gas ions to physically chip atoms off a target material, allowing them to coat a substrate in a highly controlled vacuum environment.

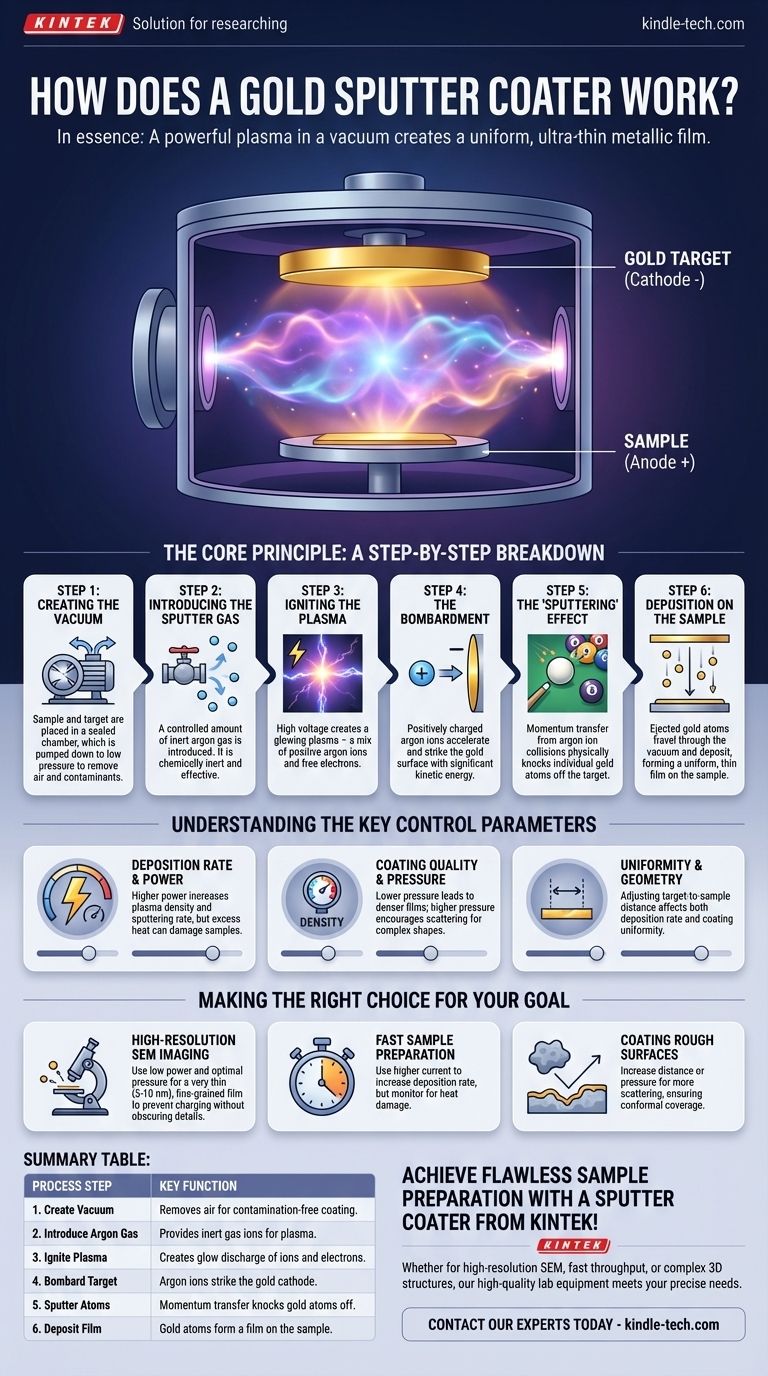

The Core Principle: A Step-by-Step Breakdown

A sputter coater is a type of Physical Vapor Deposition (PVD) system. To understand its operation, we can break it down into a sequence of distinct physical events.

Step 1: Creating the Vacuum

First, the sample and the gold target are placed inside a sealed chamber, which is then pumped down to a low pressure, creating a vacuum.

This vacuum is critical for two reasons. It removes air and other contaminant particles that could interfere with the coating, and it allows the sputtered gold atoms to travel freely from the target to the sample without colliding with air molecules.

Step 2: Introducing the Sputter Gas

A small, precisely controlled amount of an inert gas, almost always argon, is introduced into the chamber.

Argon is chosen because it is chemically inert, meaning it won't react with the target or sample. It also has sufficient mass to effectively dislodge gold atoms upon impact.

Step 3: Igniting the Plasma

A high voltage is applied between two electrodes inside the chamber. The gold target is configured as the cathode (negative electrode), and the sample stage often acts as or is near the anode (positive electrode).

This strong electric field energizes the argon gas, stripping electrons from the argon atoms and creating a glowing plasma—a mix of positively charged argon ions and free electrons.

From Gold Target to Sample Coating

Once the plasma is established, the coating process begins. The positive and negative charges create a powerful and directed mechanism for moving atoms.

Step 4: The Bombardment

The positively charged argon ions in the plasma are strongly attracted to and accelerate toward the negatively charged gold target.

They strike the surface of the gold target with significant kinetic energy, creating a process of atomic-scale bombardment.

Step 5: The "Sputtering" Effect

When an argon ion collides with the target, it transfers its momentum, physically knocking loose one or more gold atoms. This ejection of target atoms is the "sputtering" effect.

This is a purely mechanical process, similar to a cue ball breaking a rack of billiard balls, but on an atomic level.

Step 6: Deposition on the Sample

The ejected gold atoms travel in straight lines through the low-pressure chamber. When they encounter a surface—your sample—they stick to it.

Over a period of seconds to minutes, these atoms accumulate on the sample, forming a thin, continuous, and highly uniform layer of gold.

Understanding the Key Control Parameters

The quality and thickness of the sputtered film are not accidental. They are controlled by several key process variables, which you can adjust to achieve your desired result.

Deposition Rate and Power

The sputter current and voltage directly control the density and energy of the plasma. Higher power leads to more intense bombardment of the target, which increases the rate of sputtering and shortens the time needed to achieve a desired thickness. However, excessively high power can also heat and potentially damage sensitive samples.

Coating Quality and Pressure

The pressure of the argon gas inside the chamber is a critical parameter. Lower pressure means fewer gas collisions, leading to a more direct path for sputtered atoms and often a denser, more reflective film. Higher pressure can result in more gas scattering, which can be useful for coating complex, three-dimensional shapes but may lead to a less dense coating.

Uniformity and Geometry

The distance from the target to the sample affects both the deposition rate and the coating's uniformity. A shorter distance increases the coating speed but may reduce uniformity across a larger sample. A greater distance improves uniformity at the cost of a slower deposition rate.

Making the Right Choice for Your Goal

To properly use a sputter coater, you must tailor the process parameters to your specific application, most commonly preparing non-conductive samples for Scanning Electron Microscope (SEM) imaging.

- If your primary focus is high-resolution SEM imaging: Use a low power setting and optimal pressure to deposit a very thin (5-10 nm), fine-grained gold film that prevents sample charging without obscuring fine surface details.

- If your primary focus is fast sample preparation: Use a higher current to increase the deposition rate, but monitor the sample for any signs of heat damage.

- If your primary focus is coating a rough or complex surface: Consider increasing the target-to-sample distance or using a slightly higher argon pressure to encourage more scattering and ensure conformal coverage.

By understanding these core principles, you can precisely control the sputter coating process to achieve a perfect, functional film for your specific needs.

Summary Table:

| Process Step | Key Function |

|---|---|

| 1. Create Vacuum | Removes air for contamination-free coating and direct atom travel. |

| 2. Introduce Argon Gas | Provides inert gas ions for the plasma bombardment process. |

| 3. Ignite Plasma | Creates a glow discharge of argon ions and free electrons. |

| 4. Bombard Target | Argon ions accelerate and strike the gold cathode. |

| 5. Sputter Atoms | Momentum transfer knocks gold atoms off the target. |

| 6. Deposit Film | Ejected gold atoms travel and stick to the sample surface. |

Achieve flawless sample preparation with a sputter coater from KINTEK!

Whether your priority is high-resolution SEM imaging, fast throughput, or coating complex 3D structures, the right equipment is critical. KINTEK specializes in high-quality lab equipment, including reliable sputter coaters and consumables, designed to meet the precise needs of modern laboratories.

Contact our experts today to discuss how our solutions can enhance your coating process and improve your results.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- How do you prepare a sample for XRF? Achieve Accurate and Reliable Analysis

- How do activators function in SHS coating? Master Gas-Phase Transport for Rapid Coating Deposition

- What is the use of drying oven in laboratory? Achieve Uniform Heat for Drying, Sterilizing, and Curing

- What is brazing in safety? Managing Toxic Fumes, Fire, and Chemical Hazards

- Why do we do calcination? Unlock the Power of Thermal Transformation

- Why is a vacuum drying oven recommended for vanadium dioxide nanopowders? Preserve Phase Purity & Nano-Structure

- What types of sensitive medical articles can be stored in ULT freezers? Preserve Critical Samples at -80°C

- Why do we need magnetic field in magnetron sputtering? Boost Deposition Rates & Film Quality