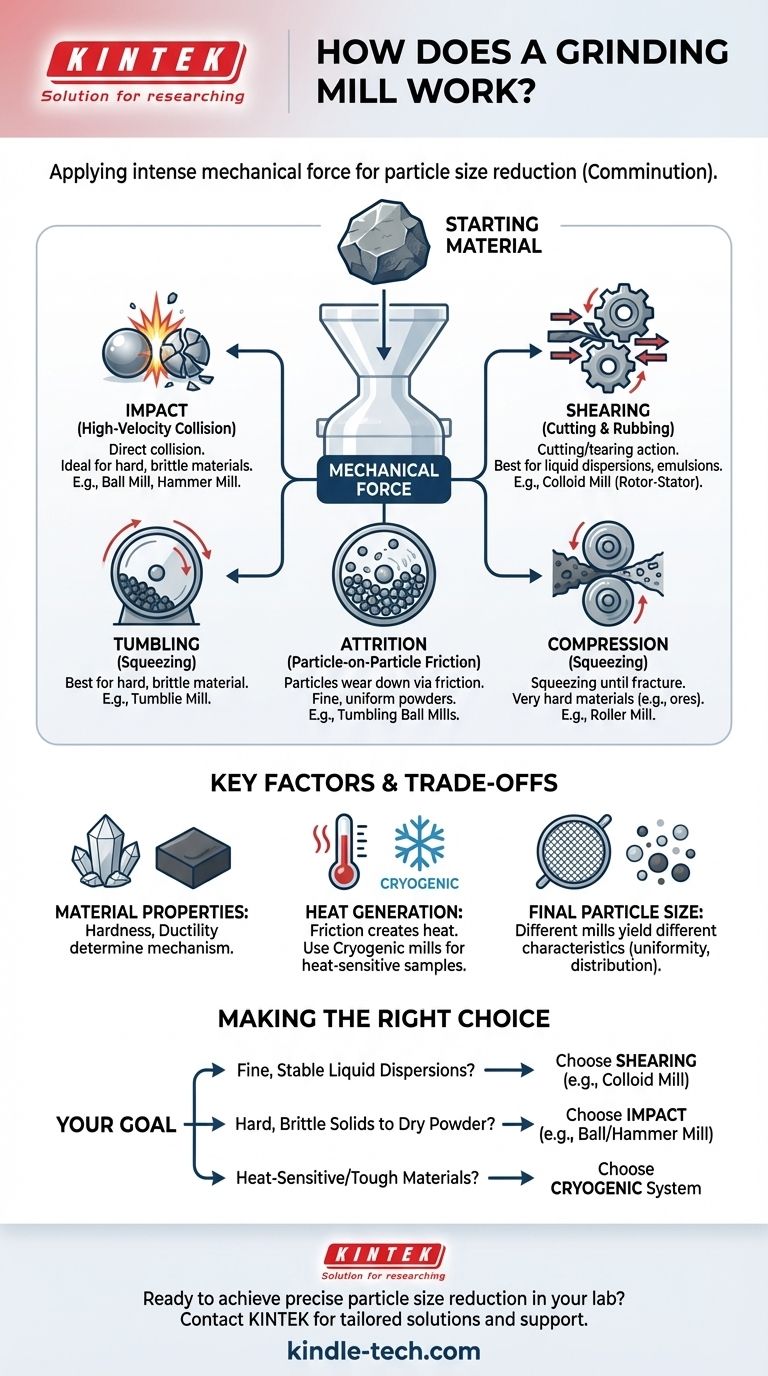

At their core, grinding mills work by applying intense mechanical force to break down solid materials into smaller particles. This process, known as comminution, is not based on a single mechanism but on a select few fundamental principles, primarily impact, compression, attrition, and shearing. The specific type of mill simply determines which of these forces is used to achieve the desired particle size and consistency.

The essential function of any grinding mill is to induce fractures in a material. The key is understanding that different mills are designed to apply different types of stress—such as high-speed collisions or intense shearing—making the choice of mill entirely dependent on the starting material and the desired final product.

The Goal: Achieving Comminution

Comminution is the engineering term for particle size reduction. Grinding is a specific form of comminution that reduces materials to a fine powder or slurry.

Why Reduce Particle Size?

Reducing particle size increases the surface area of a material. This is critical for improving reaction rates in chemical processes, enhancing the dissolution of pharmaceuticals, or creating stable mixtures and suspensions.

The Role of Mechanical Force

To break a particle, the applied force must exceed its internal strength, creating a fracture. Mills are sophisticated machines engineered to apply this force efficiently and repeatedly.

The Core Mechanisms of Grinding

Nearly all grinding mills rely on one or more of four primary mechanisms. The design of the mill is optimized to favor one mechanism over the others.

Shearing (Cutting and Rubbing)

Shearing involves forces moving in parallel but opposite directions, causing the material to be torn apart. This is highly effective for creating dispersions of solids in liquids.

A colloid mill is a perfect example of a shear-based system. It operates on a rotor-stator principle, where a high-speed rotor spins with extreme proximity to a static stator, creating intense shearing forces in the tiny gap between them.

Impact (High-Velocity Collision)

Impact involves a direct collision between the material and a grinding medium, or between the particles themselves. This method is ideal for hard and brittle materials.

Ball mills or hammer mills are common examples. In a ball mill, the material is placed in a rotating drum with hard media (like ceramic or steel balls) that repeatedly fall and strike the material, shattering it.

Attrition (Particle-on-Particle Friction)

Attrition is the process of particles rubbing against one another, gradually wearing each other down. This often occurs as a secondary effect in mills that also use impact forces.

While impact causes the initial large fractures, the subsequent tumbling and mixing action inside a mill causes particles to grind against each other, smoothing them and creating very fine powders.

Compression (Squeezing)

Compression involves squeezing the material between two surfaces until it fractures. This method is common in the initial stages of size reduction for very hard materials, like ores.

Roller mills are a classic example, passing material between two heavy rollers that crush it under immense pressure.

Understanding the Trade-offs and Key Factors

Selecting the right grinding method is a matter of balancing efficiency, cost, and the specific requirements of the material and the final product.

Material Properties Matter

The hardness and ductility of a material dictate the best grinding mechanism. Brittle materials like glass shatter well under impact, while softer, more pliable materials may require the tearing action of shearing.

Heat Generation is a Critical Side Effect

All grinding processes generate significant heat due to friction and mechanical energy transfer. This can be detrimental, potentially melting, degrading, or altering the chemical properties of the material.

This is why specialized systems like low-temperature (cryogenic) mills exist. By using a cooling system, such as a liquid nitrogen coil, the material is made extremely brittle before grinding, improving efficiency and protecting heat-sensitive components.

Final Particle Size and Distribution

Different mills produce different particle characteristics. Impact mills can produce a wider range of particle sizes, while shear-based mills are excellent for creating uniform, fine dispersions in a liquid.

Making the Right Choice for Your Goal

The optimal grinding mill is the one whose primary mechanism best matches your material and desired outcome.

- If your primary focus is creating fine, stable liquid dispersions (emulsions or suspensions): You need a mill that excels at shearing, such as a rotor-stator colloid mill.

- If your primary focus is breaking down hard, brittle solids into a dry powder: You should use an impact-based system like a ball mill or hammer mill.

- If your primary focus is processing heat-sensitive or tough, rubbery materials: You will likely need a specialized system, like a cryogenic mill, to alter the material's properties before grinding.

Ultimately, effective grinding is about applying the right type of force to overcome the internal bonds of your specific material.

Summary Table:

| Grinding Mechanism | Primary Force | Ideal For | Common Mill Types |

|---|---|---|---|

| Impact | High-velocity collision | Hard, brittle materials | Ball Mill, Hammer Mill |

| Shearing | Cutting, tearing, rubbing | Creating liquid dispersions, emulsions | Colloid Mill (Rotor-Stator) |

| Attrition | Particle-on-particle friction | Fine, uniform powders | Tumbling Ball Mills |

| Compression | Squeezing, crushing | Very hard materials (e.g., ores) | Roller Mill |

Ready to achieve precise particle size reduction in your lab?

The right grinding mill is critical for your research and production outcomes. KINTEK specializes in lab equipment and consumables, offering a range of mills tailored to your specific material and particle size goals. Our experts can help you select the ideal solution—whether you need impact for brittle materials, shearing for stable dispersions, or cryogenic grinding for heat-sensitive samples.

Contact us today to discuss your application and let KINTEK provide the reliable equipment and support your laboratory needs. Get in touch via our contact form!

Visual Guide

Related Products

- Laboratory Grinding Mill Mortar Grinder for Sample Preparation

- Laboratory Micro Tissue Grinding Mill Grinder

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Single Horizontal Jar Mill

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

People Also Ask

- What is the function of using an agate mortar during the precursor mixing stage of sulfide solid electrolyte synthesis?

- Why is an alumina mortar used for grinding dried Yttrium Oxide precursor materials? Ensure Maximum Purity and Quality

- Why is an agate mortar and pestle preferred for grinding MAX phase? Ensure Sample Purity & Zero Contamination

- What is the function of an Agate Mortar and Pestle in sodium battery preparation? Ensure Contaminant-Free Mixing

- What are the different types of laboratory mills? Choose the Right Grinder for Your Sample Material