At its core, a hammermill shredder works by brute force. It uses a series of rotating hammers, spinning at high velocity inside a steel chamber, to repeatedly strike and shatter material. This violent process continues until the material is pulverized into particles small enough to pass through a sizing screen at the bottom of the chamber.

A hammermill does not cut or slice material; it pulverizes it through a series of high-energy impacts. Its effectiveness comes from shattering material against hardened surfaces until it is small enough to be discharged, making it a versatile workhorse for size reduction.

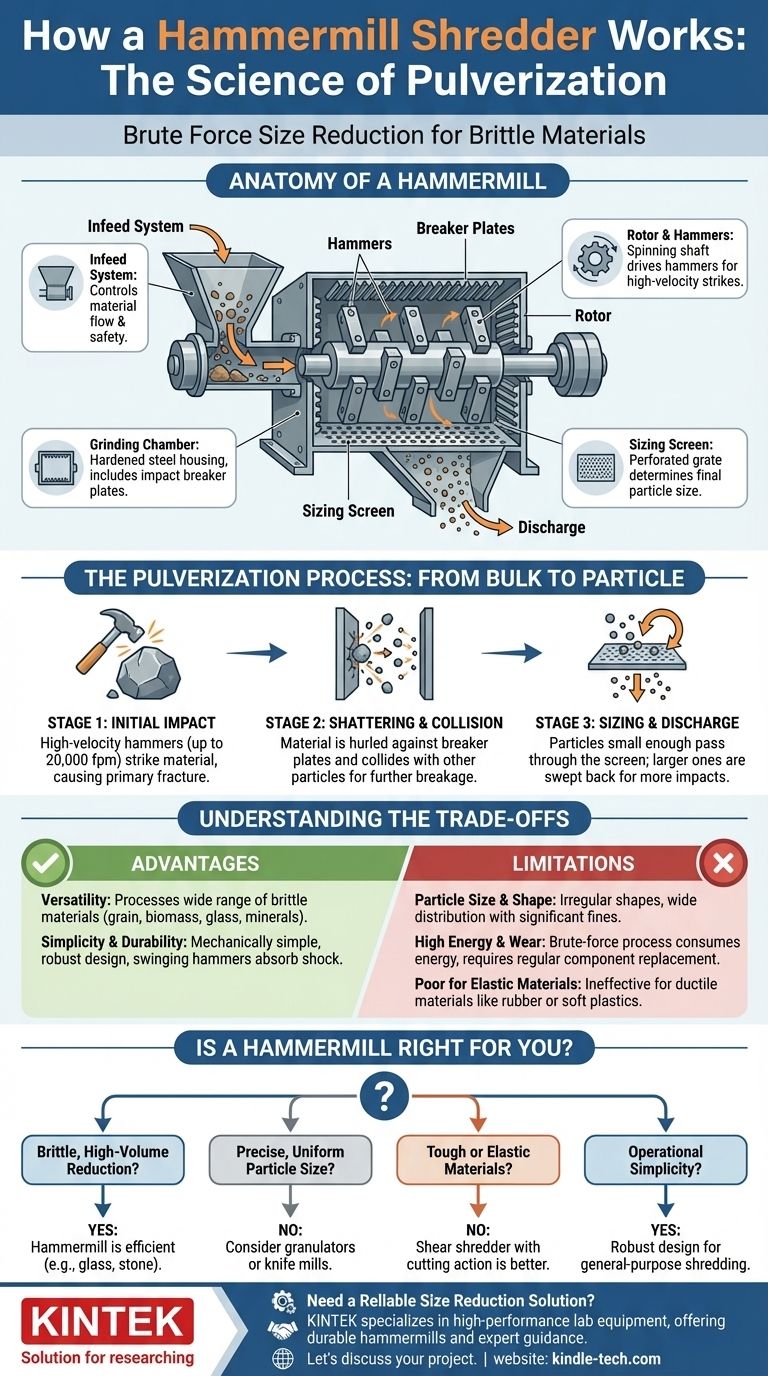

The Anatomy of a Hammermill

To truly understand the process, it's essential to understand the core components and the role each one plays.

The Infeed System

Material is introduced into the grinding chamber through an infeed chute or hopper. The design of this system is critical for controlling the flow of material and ensuring safe operation.

The Rotor and Hammers

The rotor is the central, spinning shaft that drives the entire operation. Attached to this rotor are multiple hammers—heavy-duty plates of hardened steel.

In most designs, these hammers are not rigidly fixed but are pinned to the rotor, allowing them to swing freely. This is a crucial design feature that allows the hammers to pivot back if they strike an un-crushable or overly dense object, protecting the rotor and motor from catastrophic shock damage.

The Grinding Chamber

This is the hardened steel housing where all the action takes place. The interior walls, often lined with ridged breaker plates, serve as a primary impact surface. As the hammers hurl material at high speed, it smashes against these plates, causing it to fracture and break apart.

The Sizing Screen

A perforated screen, or grate, forms the floor or a portion of the grinding chamber. The size of the holes in this screen dictates the maximum size of the finished product. Material remains in the chamber, subject to continuous impacts, until it is reduced to a size that allows it to pass through these perforations.

The Pulverization Process: From Bulk to Particle

The journey of material through a hammermill is a violent and rapid one, happening in a continuous cycle.

Stage 1: Initial Impact

As material enters the chamber, it is immediately struck by the tips of the hammers, which can be moving at speeds exceeding 20,000 feet per minute (100 m/s). This initial, high-velocity impact is responsible for the primary fracture.

Stage 2: Shattering and Collision

The material is then violently accelerated and thrown against the breaker plates lining the chamber, causing further shattering. It also collides with other particles suspended in the chaos, leading to even more size reduction in a process known as particle-on-particle attrition.

Stage 3: Sizing and Discharge

The hammers and the airflow they generate continuously sweep the pulverized material across the face of the sizing screen. Particles that are small enough fall through the screen and are discharged from the mill. Larger particles are swept back up into the path of the hammers for another round of impacts.

Understanding the Trade-offs

While powerful, the hammermill is not the perfect solution for every application. Understanding its inherent strengths and weaknesses is key to using it effectively.

Key Advantage: Versatility

A hammermill's primary strength is its ability to process a vast range of brittle or friable materials. This includes everything from grain, biomass, and wood waste to glass, minerals, and certain types of scrap metal.

Key Advantage: Simplicity and Durability

The design is mechanically simple and robust. With swinging hammers to absorb shock and only a few primary wear parts (hammers and screens), they are generally reliable and relatively easy to maintain.

Limitation: Particle Size and Shape

A hammermill produces material through fracture. This means the final product will have an irregular shape and a wider particle size distribution compared to a cutting mill. While the screen sets the maximum output size, a significant portion of "fines" (very small particles) is an expected byproduct.

Limitation: High Energy and Wear

This is a brute-force process that consumes significant energy and generates heat. The hammers, screens, and breaker plates are high-wear components that require regular inspection and replacement, representing the primary operational cost.

Limitation: Poor for Elastic Materials

Hammermills are often ineffective for ductile or elastic materials like rubber, textiles, or soft plastics. These materials tend to absorb the hammer impacts and deform rather than shatter, leading to poor processing efficiency.

Is a Hammermill Right for Your Application?

Choosing a size reduction technology depends entirely on your material and your final goal.

- If your primary focus is high-volume reduction of brittle materials: A hammermill is an exceptionally efficient and cost-effective choice for things like glass, stone, or dry biomass.

- If your primary focus is a precise, uniform particle size: You should consider alternative technologies like granulators or knife mills, as a hammermill inherently produces a wider range of particle sizes.

- If your primary focus is processing tough or elastic materials: A low-speed, high-torque shear shredder with a cutting action will be far more effective and energy-efficient than an impact-based hammermill.

- If your primary focus is operational simplicity for general-purpose shredding: The robust and straightforward design of a hammermill makes it a leading contender for many waste processing and recycling applications.

Understanding that the hammermill is a master of pulverization, not precision cutting, is the key to deploying it effectively.

Summary Table:

| Component | Function |

|---|---|

| Rotor & Hammers | Spins at high speed to strike and shatter material. |

| Grinding Chamber | Hardened steel housing with breaker plates for impact. |

| Sizing Screen | Perforated screen that controls final particle size. |

| Infeed System | Hopper or chute that safely introduces material. |

| Process Stage | Description |

|---|---|

| Initial Impact | High-velocity hammer strike causes primary fracture. |

| Shattering | Material is thrown against breaker plates for further reduction. |

| Sizing & Discharge | Particles small enough pass through the screen for discharge. |

| Pros & Cons | Details |

|---|---|

| Advantages | Highly versatile for brittle materials; simple, durable design. |

| Limitations | Wide particle size distribution; high energy use and wear; poor for elastic materials. |

Need a Reliable Solution for Your Size Reduction Challenges?

KINTEK specializes in high-performance lab equipment, including robust shredding and milling solutions. Whether you're processing brittle materials, biomass, or other substances, our expertise ensures you get the right equipment for efficient, reliable particle size reduction.

We provide:

- Durable hammermills designed for tough applications.

- Expert guidance to select the ideal technology for your specific material and output goals.

- Comprehensive support to maximize your operational efficiency and minimize downtime.

Let's discuss your project. Contact our experts today to find the perfect size reduction system for your laboratory needs.

Visual Guide

Related Products

- Laboratory Sealed Hammer Crusher for Efficient Sample Preparation

- Laboratory Single Horizontal Jar Mill

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Jar Mill with Agate Grinding Jar and Balls

People Also Ask

- What are the primary functions of using a ball mill for BZCY72 powder? Achieve High Purity and Enhanced Sintering

- What are the factors affecting the efficiency of milling operations? Optimize Your Grinding Process for Maximum Output

- Why is the grinding process essential for catalyst support pretreatment? Maximize Zirconia-Based Catalyst Efficiency

- What is the function of a vibratory ball mill in the synthesis of lithium-rich double perovskite precursors? Maximize Reactivity

- How can you improve the efficiency of a ball mill? Optimize Speed, Media, and Material Charge for Peak Performance

- Why is high-speed stirring equipment necessary in carbon nanotube adsorption experiments? Optimize Your Lab Results

- What is the advantage of using high-hardness Zirconia grinding balls for the milling of Na3SbS4-xSex electrolytes?

- What is the function of a ball mill in Reaction Bonded Boron Carbide? Achieve Optimal Powder Homogeneity for RBBC