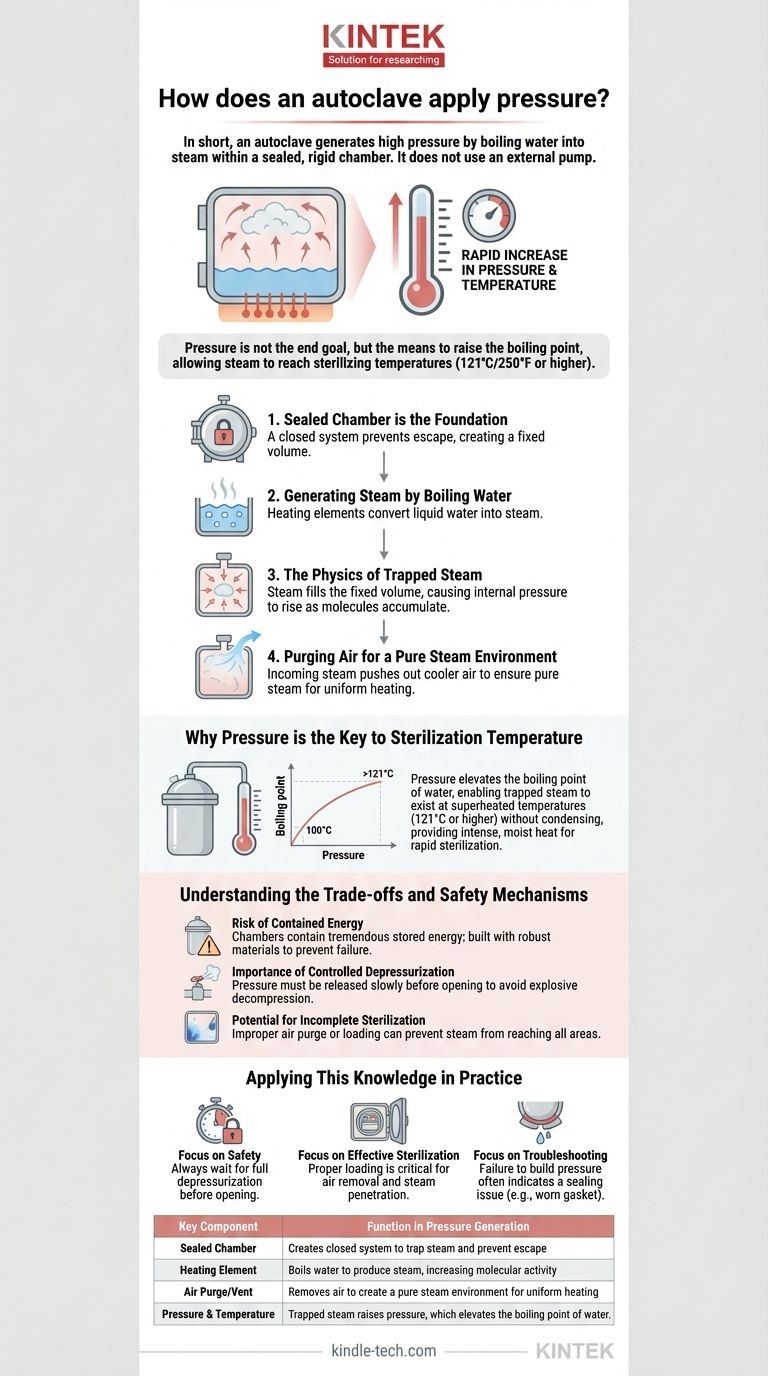

In short, an autoclave generates high pressure by boiling water into steam within a sealed, rigid chamber. It does not use an external pump to apply pressure. As the heating elements turn water into steam, the steam fills the chamber and, because it cannot escape, its accumulation causes a rapid and predictable increase in both internal pressure and temperature.

The central concept to understand is that pressure is not the end goal, but the means to an end. An autoclave traps steam to increase pressure, which in turn raises the boiling point of water. This allows the steam to achieve temperatures far above 100°C (212°F), enabling the rapid and complete sterilization of materials through intense, moist heat.

The Core Principle: From Water to High-Pressure Steam

To grasp how an autoclave works, think of it not as a pressure pump, but as a highly sophisticated, industrial-strength pressure cooker. The process relies on a direct relationship between temperature, pressure, and the state of water.

A Sealed Chamber is the Foundation

An autoclave's primary component is its pressure chamber, a vessel with a locking, gasket-sealed door. When this door is closed and locked, the chamber becomes a closed system, preventing anything from escaping.

Generating Steam by Boiling Water

At the start of a cycle, a built-in heating system boils a reservoir of water inside or connected to the chamber. This process converts the liquid water into gaseous water, or steam.

The Physics of Trapped Steam

As steam is generated, it fills the chamber's fixed volume. Because the steam molecules cannot escape the sealed chamber, they accumulate, leading to a constant increase in internal pressure. This is a fundamental principle of gas physics: adding more gas to a fixed volume inevitably raises the pressure.

Purging Air for a Pure Steam Environment

Early in the cycle, the incoming steam is used to push the cooler, less-dense air out of the chamber through a vent. This air removal step is critical. Air is a poor conductor of heat compared to steam, and any trapped air pockets can create "cold spots" that prevent proper sterilization. Once the air is purged, the chamber contains an environment of pure, saturated steam.

Why Pressure is the Key to Sterilization Temperature

The pressure itself does not sterilize. Rather, it creates the conditions necessary for the steam to reach sterilizing temperatures.

The Relationship Between Pressure and Boiling Point

At standard sea-level atmospheric pressure, water boils at 100°C (212°F). Above this temperature, it turns to steam. However, if you increase the pressure on water, you also increase its boiling point.

Reaching Sterilizing Temperatures

Inside the pressurized autoclave, the boiling point of water is significantly elevated. This allows the trapped steam to exist at temperatures of 121°C (250°F) or higher without condensing back into water. It is this superheated, high-pressure steam that serves as the sterilizing agent.

How High-Temperature Steam Sterilizes

The combination of high temperature and moisture is exceptionally lethal to microorganisms. This moist heat rapidly penetrates materials and denatures the essential proteins and enzymes within bacteria, viruses, and spores, rendering them inactive and non-reproducible.

Understanding the Trade-offs and Safety Mechanisms

The process of generating high-pressure steam is effective but comes with inherent risks that are managed through robust engineering and safety protocols.

The Risk of Contained Energy

A chamber containing high-pressure, high-temperature steam holds a tremendous amount of stored energy. This is why autoclave chambers are built from thick steel or gunmetal and are subject to stringent manufacturing and testing standards. A structural failure would result in a violent, explosive release of energy.

The Importance of Controlled Depressurization

At the end of a sterilization cycle, the pressure must be released slowly and safely through a dedicated vent valve. Opening the door while the chamber is still pressurized would cause an explosive decompression and could lead to severe burns from the escaping steam and boiling-over of any liquids inside.

The Potential for Incomplete Sterilization

The effectiveness of the entire process depends on achieving a pure steam environment. If the initial air purge is incomplete due to improper loading (e.g., packing items too densely) or a mechanical fault, the required sterilization temperature may not be reached in all areas of the load, leading to a failed cycle.

Applying This Knowledge in Practice

Understanding the mechanism of pressure generation allows you to operate an autoclave more effectively and safely.

- If your primary focus is safety: Always remember that the pressure is generated internally by steam, and you must wait for the machine to complete its cycle and fully depressurize before attempting to open the door.

- If your primary focus is effective sterilization: Understand that pressure's main role is to enable high temperatures, and proper loading is critical to ensure air is removed and steam can reach every surface.

- If your primary focus is troubleshooting: A failure to build pressure often points to a problem with the system's ability to remain sealed, such as a worn-out door gasket or a leaky valve.

Grasping that an autoclave creates its own pressure by trapping steam is the key to using it safely and achieving reliable sterilization.

Summary Table:

| Key Component | Function in Pressure Generation |

|---|---|

| Sealed Chamber | Creates a closed system to trap steam and prevent escape. |

| Heating Element | Boils water to produce steam, increasing molecular activity. |

| Air Purge/Vent | Removes air to create a pure steam environment for uniform heating. |

| Pressure & Temperature | Trapped steam raises pressure, which elevates the boiling point of water. |

Achieve Uncompromising Sterilization with KINTEK Autoclaves

Understanding the precise physics of steam and pressure is critical for effective sterilization. KINTEK specializes in high-performance laboratory autoclaves that deliver reliable, safe, and consistent results. Our equipment is engineered with robust safety mechanisms and precise controls to ensure optimal performance for your specific laboratory needs.

Let us help you enhance your lab's safety and efficiency. Contact our experts today to find the perfect autoclave solution for your application.

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What is the normal temperature of an autoclave? Achieve Sterile Confidence with Precise Control

- What critical environmental conditions does a laboratory autoclave provide for evaluating wear resistance? - KINTEK

- What role does an autoclave play in the acid treatment for microalgae disruption? Unlock High-Yield Cell Pretreatment

- What types of items and materials can be processed in a laboratory autoclave? Essential Guide for Lab Safety

- What is the life expectancy of an autoclave machine? Maximize Your Investment with Proper Care