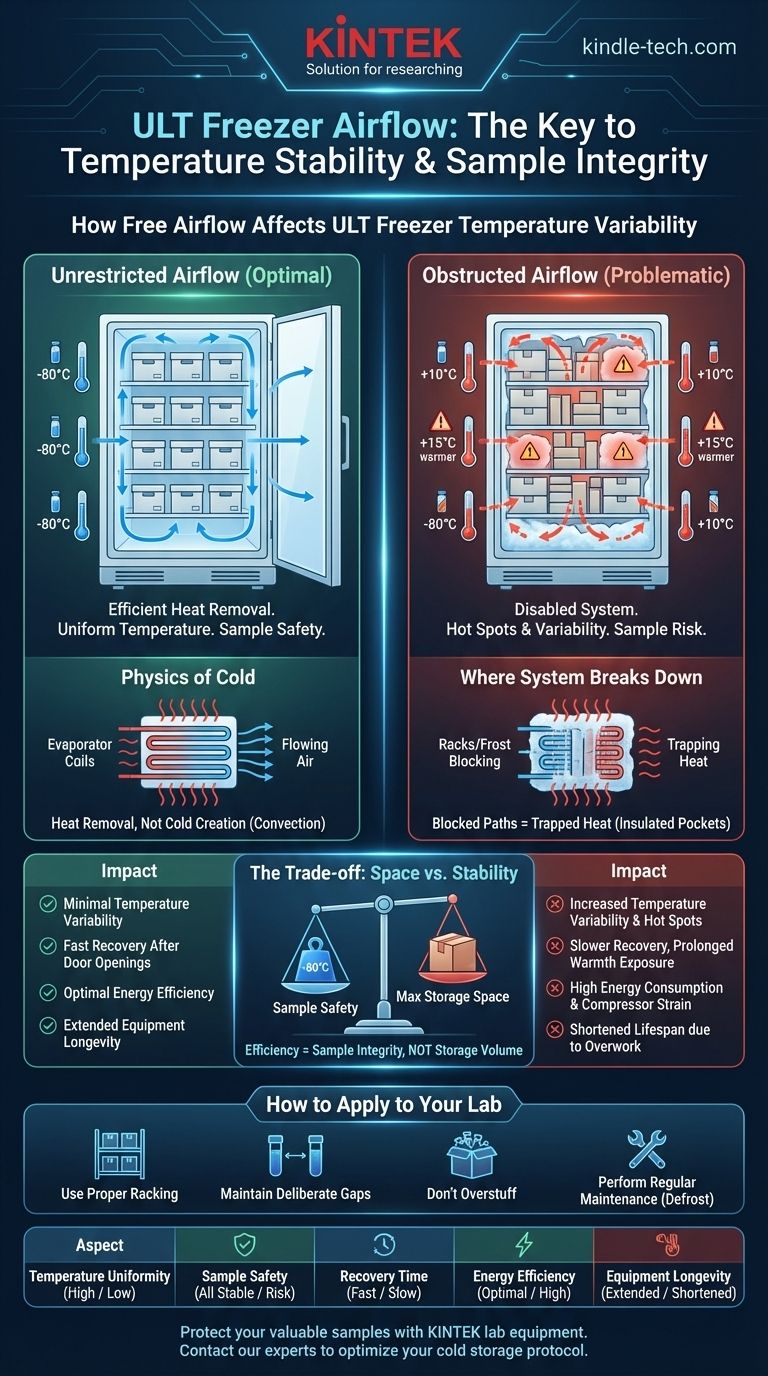

In short, unrestricted airflow is the single most important factor for minimizing temperature variability in a ULT freezer. When air circulates freely, the refrigeration system can efficiently remove heat from every corner of the chamber, preventing the formation of "hot spots." This ensures all your samples are maintained at a uniform, stable temperature, which is critical for their long-term integrity.

The core function of a ULT freezer is to actively remove heat, and it uses circulating air as the primary medium for this heat transfer. Obstructing airflow effectively disables this system in localized areas, creating a mosaic of different temperatures that puts samples at risk.

The Physics of Cold: How a ULT Freezer Manages Temperature

To understand the importance of airflow, you must first understand that freezers do not "create cold." Instead, they are heat pumps, working tirelessly to move thermal energy from inside the cabinet to the outside environment.

Heat Removal, Not Cold Creation

A refrigeration system circulates a refrigerant through a series of coils. The evaporator coils inside the freezer absorb heat from the air, and the condenser coils outside the freezer release that heat into the room.

The Critical Role of Convection

This heat transfer process relies entirely on convection. The air inside the freezer must be able to move freely, pick up heat from your samples and the interior walls, and carry that heat to the cold evaporator coils to be removed.

Where the System Breaks Down

If racks, boxes, or frost block the path between the samples and the evaporator coils, the air cannot circulate. Heat in that blocked-off zone becomes trapped, and the temperature begins to rise, regardless of the freezer's setpoint.

The Impact of Obstructed Airflow

Failing to manage airflow has direct and damaging consequences for both your samples and the freezer itself. It is the leading cause of temperature instability in a well-functioning unit.

The Creation of Hot Spots

When boxes are packed too tightly or pushed against the freezer's inner walls, they create insulated pockets. Air cannot penetrate these areas, so heat is not removed. While the freezer's main sensor may read -80°C, these hot spots can easily be 10-15°C warmer, rising above the critical -70°C threshold.

Increased Temperature Variability

The result is high temperature variability across the freezer. Samples near the evaporator coils might be perfectly stable, while those in a blocked-off corner are undergoing dangerous temperature fluctuations, compromising their integrity.

Slower Recovery After Door Openings

Every time the door is opened, warm, moist air floods the chamber. A freezer with good airflow can quickly circulate the cold air to absorb this new heat load and return to its setpoint. An obstructed freezer will struggle, significantly extending the time your samples are exposed to elevated temperatures.

Strain on the Compressor

The freezer's control system will detect that its target temperature isn't being met and force the compressor to run longer and harder. This constant overwork to cool down unresponsive hot spots leads to higher energy consumption and drastically shortens the lifespan of the freezer's most expensive components.

Understanding the Trade-offs: Space vs. Stability

In any lab, storage space is a precious commodity. This creates a natural tension between the desire to maximize storage capacity and the need to ensure sample safety.

The Temptation to "Fill Every Gap"

It is tempting to fit as many racks and boxes as possible into a freezer. On the surface, this seems like an efficient use of an expensive piece of equipment.

The Hidden Cost of Overpacking

However, this is a false economy. The short-term gain in storage density comes at the immense risk of sample loss. The cost of compromised research or irreplaceable biological specimens far exceeds the cost of purchasing an additional freezer.

The True Measure of Efficiency

A truly efficient ULT freezer is not one that is packed to its physical limit, but one that maintains a stable and uniform temperature for all its contents. Efficiency is measured by sample integrity, not storage volume.

How to Apply This to Your Lab

Implementing proper airflow management is a matter of disciplined lab practice. By treating the space inside your freezer as a critical component, you ensure its performance.

- Use Proper Racking Systems: Use racks designed for your freezer model. These inherently create organized channels for vertical and horizontal airflow.

- Maintain Deliberate Gaps: Always leave an inch or two of space between racks and between the racks and the freezer's walls, floor, and ceiling. Never place items directly on the freezer floor.

- Don't Overstuff Racks or Boxes: Just as you leave space between racks, you must also allow for air to circulate within them. Avoid cramming boxes so tightly that air cannot move around them.

- Perform Regular Maintenance: Frost buildup is a major impediment to airflow and also acts as an insulator. Regularly defrost your freezer and clear away any ice that could obstruct air paths.

Making the Right Choice for Your Samples

Your approach to freezer loading should be dictated by your ultimate goal: the preservation of your valuable samples.

- If your primary focus is sample integrity and reproducibility: You must prioritize airflow management over maximizing storage density.

- If your primary focus is long-term operational cost: Proper airflow reduces compressor strain and energy consumption, making it the most cost-effective strategy.

- If your primary focus is maximizing storage space: Re-evaluate your needs; overpacking is never the right solution and an additional storage unit is a far safer investment.

By treating airflow as an active and essential part of your cold storage protocol, you ensure your freezer provides the stable, reliable environment your work depends on.

Summary Table:

| Aspect | Unrestricted Airflow | Obstructed Airflow |

|---|---|---|

| Temperature Uniformity | High (stable across chamber) | Low (creates hot spots) |

| Sample Safety | All samples maintained at setpoint | Risk of temperatures rising above -70°C |

| Recovery Time | Fast after door openings | Slow, prolonged exposure to warmth |

| Energy Efficiency | Optimal, compressor runs normally | High consumption, compressor strain |

| Equipment Longevity | Extended lifespan | Shortened due to overwork |

Protect your valuable samples with the right lab equipment from KINTEK.

Proper airflow management is just one part of reliable sample storage. KINTEK specializes in high-performance lab equipment and consumables designed to meet the rigorous demands of modern laboratories. Whether you need a new ULT freezer, efficient racking systems, or expert advice on optimizing your cold storage setup, we have the solutions to ensure your samples remain stable and secure.

Let us help you enhance your lab's efficiency and sample integrity. Contact our experts today to discuss your specific needs and discover how KINTEK can support your research with reliable, precision equipment.

Visual Guide

Related Products

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 938L Vertical Ultra Low Temperature Freezer for Advanced Laboratory Storage

- 808L Precision Laboratory Vertical Ultra Low Temperature Freezer

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 108L Vertical Ultra Low Temperature ULT Freezer

People Also Ask

- Why are ULT freezers considered vital equipment in labs? Ensuring Uncompromised Sample Integrity for Critical Research

- How are advancements in compressor technology and refrigerant fluids improving ULT freezers? Boost Efficiency & Cut Costs

- How is temperature controlled in ultra low temperature freezers? A Guide to Stable -80°C Storage

- What is convection-based cooling in ultra-low temperature freezers? Achieve Superior Temperature Stability for Your Samples

- What are the different types of ultra-low temperature freezers available? Choose the Right ULT Freezer for Your Lab