Particle size is the central variable that dictates the entire strategy of a ball milling operation. In essence, the size of your starting material determines the ideal size of your grinding media, and the target final particle size dictates the type of force—impact versus attrition—you need to prioritize. Failing to align these factors results in inefficiency, long processing times, and poor outcomes.

The core challenge of ball milling is not just making particles smaller, but continuously matching the energy of the grinding system to the evolving fracture requirements of the material. Effective size reduction depends on a dynamic balance between the size of the grinding media and the size of the particles being milled.

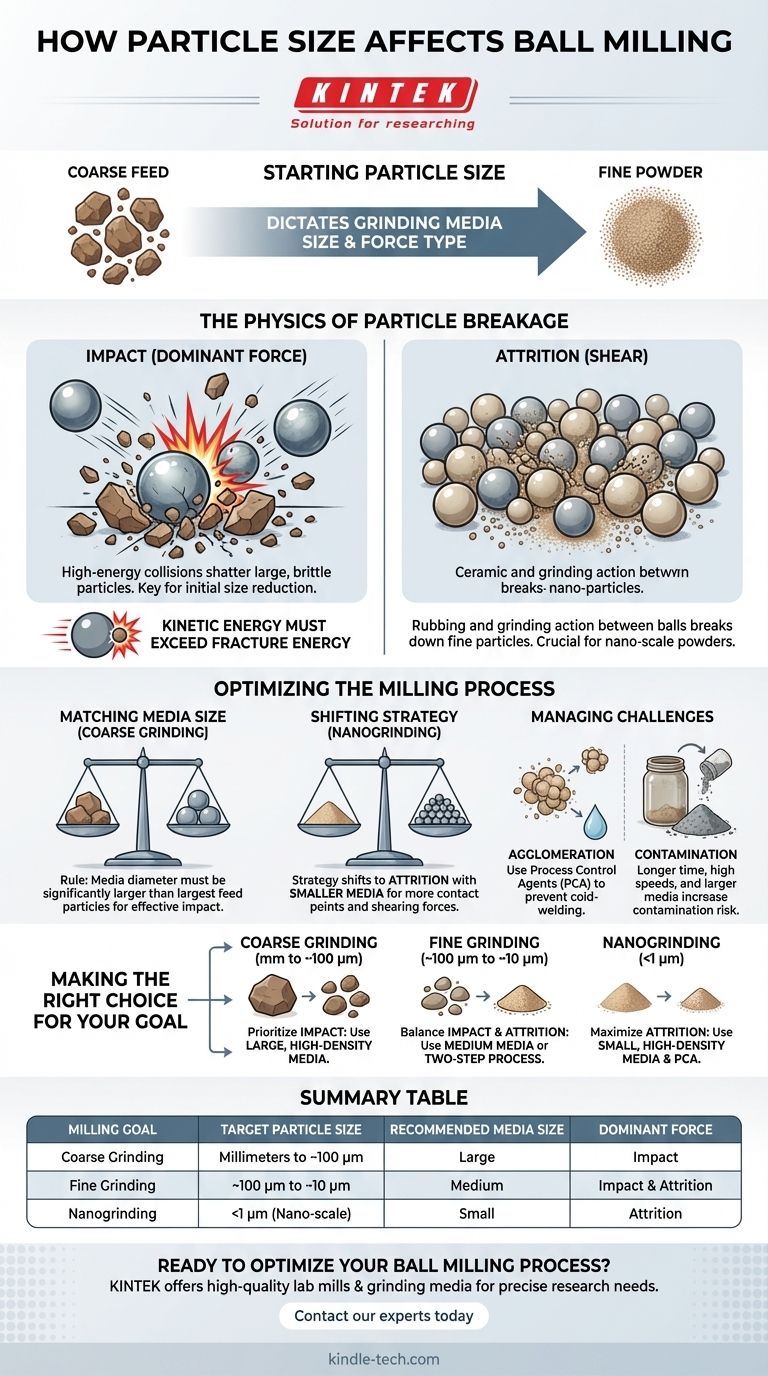

The Physics of Particle Breakage

To control a ball milling process, you must first understand the two primary mechanisms responsible for breaking particles down.

Impact vs. Attrition

Impact is the dominant force at the beginning of the milling process. It involves high-energy collisions where large, heavy balls strike and shatter coarse feed material. This is a process of brittle fracture.

Attrition (or shear) becomes critical as particles get finer. This is a rubbing and grinding action that occurs as balls slide past one another, breaking down small particles caught between them. This is the key to achieving very fine or nano-scale powders.

The Role of Kinetic Energy

The grinding media—the balls—do the work. The energy they deliver in a collision must be greater than the energy required to fracture the particle.

If the balls are too small for the feed material, their impacts will lack the necessary kinetic energy to cause a fracture. The energy will be absorbed, and no size reduction will occur.

Conversely, using very large balls to grind already fine powder is inefficient. The number of collision events is low, and the massive energy is wasted, often converting to heat or causing particles to embed into the media instead of fracturing.

Optimizing the Milling Process

Success in ball milling comes from adapting your parameters—primarily media size—as the material's particle size changes.

Matching Media Size to Feed Particles

A crucial rule of thumb is that the diameter of the grinding media should be significantly larger than the largest particles in your starting material.

This ensures the balls have sufficient mass and momentum to create high-impact fracture events, rapidly breaking down the bulk of the coarse feed. Too small a media choice at this stage will dramatically increase milling time or fail entirely.

Shifting Strategy for Nanogrinding

As particles shrink into the micron and sub-micron range, their behavior changes. High-impact events become less effective.

To achieve nano-scale particles, the strategy must shift to promoting attrition. This is accomplished by using much smaller grinding media. Smaller balls create vastly more contact points and promote the shearing forces needed to break down fine powders.

The Problem of Agglomeration

As particles become smaller, their surface area to volume ratio increases exponentially. This high surface energy makes them prone to re-agglomerating or "cold-welding" back together, especially during dry milling.

This effect can create a practical limit on the final achievable particle size. Often, a Process Control Agent (PCA), like a surfactant or alcohol, is added to coat the particles and prevent them from sticking together.

Understanding the Trade-offs

Optimizing for one factor, like speed, often comes at the cost of another, like purity. A successful process requires balancing these competing factors.

Grinding Efficiency and Time

The rate of particle size reduction is not linear. It is typically rapid at the start when breaking large, brittle particles.

The process slows down considerably as the particles get smaller. More energy is required to fracture fine particles, and the chances of agglomeration increase, leading to diminishing returns on milling time.

The Risk of Contamination

Milling is an abrasive process. The constant collision and grinding wears down both the media and the inner walls of the milling jar.

This wear introduces material from the jar or balls into your powder, causing contamination. Longer milling times, higher rotational speeds, and using larger, heavier media all accelerate this process.

Wet vs. Dry Milling

Particle size also affects the bulk properties of the powder. In dry milling, very fine particles can cake and coat the media, cushioning impacts and halting the process.

In wet milling, the particle size distribution affects the viscosity of the slurry. An overly viscous slurry can impede the motion of the balls, dramatically reducing grinding efficiency.

Making the Right Choice for Your Goal

Your specific objective determines your milling parameters. Use these guidelines to create a logical starting point for your process development.

- If your primary focus is coarse grinding (e.g., from millimeters down to ~100 microns): Prioritize impact forces by using large, high-density grinding media relative to your feed size.

- If your primary focus is fine grinding (e.g., from ~100 microns down to ~10 microns): Use a medium-sized media to balance impact and attrition, or consider a two-step process starting with larger media and finishing with smaller media.

- If your primary focus is achieving nano-scale particles (<1 micron): Use small, high-density media to maximize attrition, operate at optimal speeds to avoid inefficient collisions, and strongly consider using a process control agent to prevent agglomeration.

By understanding these relationships, you can transform your ball milling from a trial-and-error exercise into a predictable and controlled engineering task.

Summary Table:

| Milling Goal | Target Particle Size | Recommended Media Size | Dominant Force |

|---|---|---|---|

| Coarse Grinding | Millimeters to ~100 µm | Large | Impact |

| Fine Grinding | ~100 µm to ~10 µm | Medium | Impact & Attrition |

| Nanogrinding | <1 µm (Nano-scale) | Small | Attrition |

Ready to optimize your ball milling process? Whether you're working on coarse grinding or achieving nano-scale powders, KINTEK has the expertise and equipment to help. Our range of high-quality lab mills and grinding media is designed to meet the precise needs of your research and development. Contact our experts today to discuss your specific application and ensure efficient, contamination-free results.

Visual Guide

Related Products

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- What is the primary function of a planetary ball mill in LAGP synthesis? Achieve High-Purity Solid-State Electrolytes

- What is the primary function of a planetary ball mill in the synthesis of nano-Mg2Si powders? Master Nanoscale Synthesis

- Why are ball milling and grinding systems essential in the physical pretreatment of cellulosic textile waste?

- What role does a planetary ball mill play in the synthesis of LZTC solid-state electrolytes? Enhancing Ionic Conductivity

- What is the function of a planetary ball mill for B4C/Al composites? Achieving Superior Material Homogenization

- How do you calculate ball mill residence time? Master Throughput and Product Fineness

- Why is ball milling used for LiFePO4 electrode powder pretreatment? Optimize Your Cold Sintering Success

- What is the function of a ball mill in LATP preparation? Optimize Precursors for High-Performance Solid Electrolytes