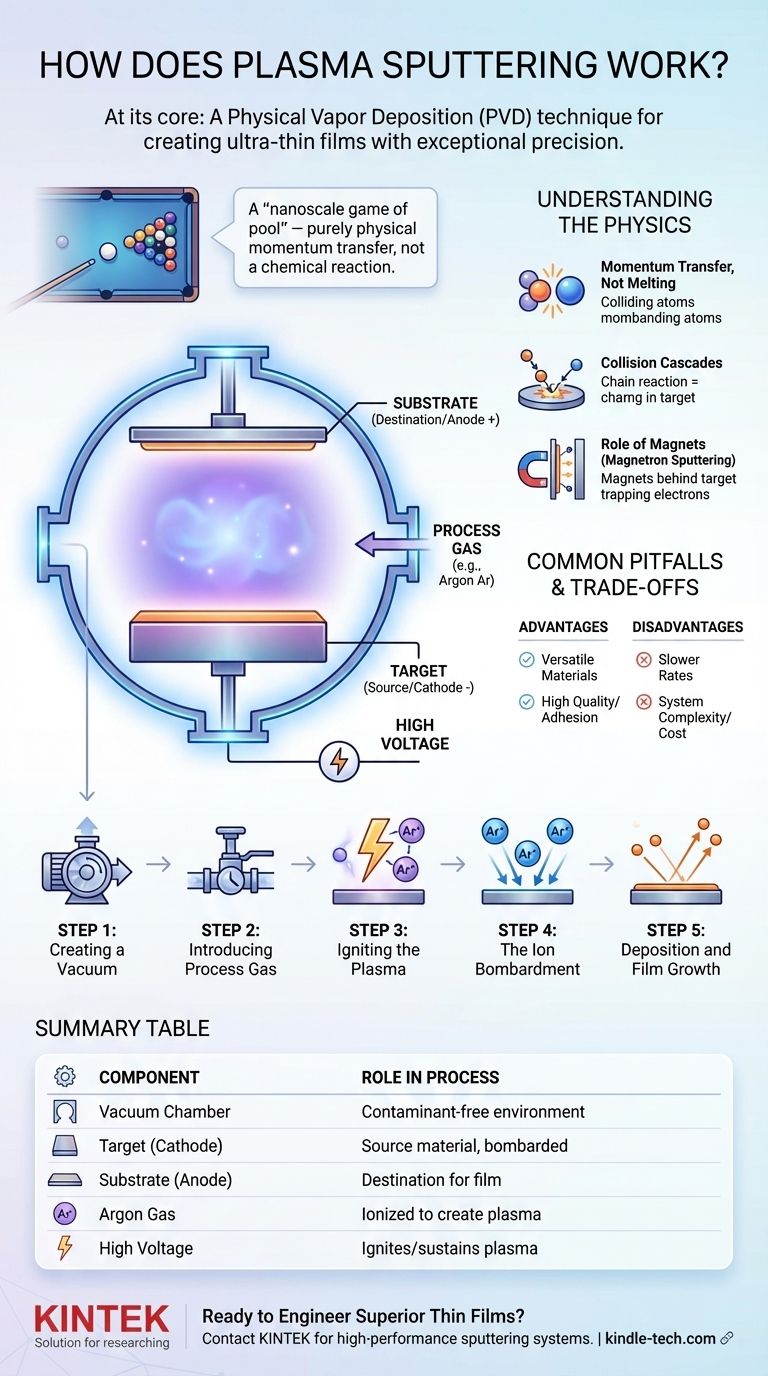

At its core, plasma sputtering is a physical vapor deposition (PVD) technique used to create ultra-thin films of material with exceptional precision. The process takes place in a vacuum and uses an energized plasma to bombard a source material, called a target. This bombardment physically knocks atoms off the target, which then travel and deposit onto a substrate, forming a uniform coating one atom at a time.

Sputtering is not a chemical reaction or a melting process. It is a purely physical mechanism of momentum transfer, best visualized as a nanoscale game of pool where energetic ions act as cue balls to eject atoms from a target material.

The Core Components of a Sputtering System

To understand how sputtering works, we must first identify the key players inside the vacuum chamber.

The Vacuum Chamber

The entire process occurs within a sealed chamber from which nearly all air has been removed. This vacuum is critical to prevent sputtered atoms from colliding with air molecules and to avoid contamination of the final film.

The Target Material (The Source)

This is a block of the pure material you wish to deposit as a thin film. It is connected to a negative voltage source, making it the cathode.

The Substrate (The Destination)

This is the object to be coated, such as a silicon wafer, glass pane, or medical implant. It is positioned to face the target and often acts as the anode in the electrical circuit.

The Process Gas (The "Ammunition")

An inert gas, most commonly Argon (Ar), is introduced into the vacuum chamber in small, controlled amounts. This gas is not part of the final film; its atoms are used as the projectiles for bombardment.

The Sputtering Process, Step-by-Step

The deposition of a thin film via sputtering follows a precise sequence of events.

Step 1: Creating a Vacuum

The chamber is sealed and pumps remove ambient air. This ensures the path from the target to the substrate is clear and that the resulting film remains uncontaminated.

Step 2: Introducing the Process Gas

A small amount of Argon gas is bled into the chamber. The pressure is low but sufficient to create the medium for the plasma.

Step 3: Igniting the Plasma

A high voltage is applied to the target material (the cathode). This powerful electric field rips electrons from the Argon atoms, creating a mixture of positively charged Argon ions (Ar+) and free electrons. This energized, ionized gas is the plasma.

Step 4: The Ion Bombardment

The positively charged Argon ions are forcefully accelerated by the electric field toward the negatively charged target. They collide with the target surface with tremendous kinetic energy.

Step 5: Deposition and Film Growth

This high-energy impact transfers momentum to the atoms of the target material, knocking them loose. These ejected atoms travel through the vacuum in a straight line and land on the substrate, where they condense and build up to form a thin, highly uniform film.

Understanding the Underlying Physics

The effectiveness of sputtering is governed by fundamental physical principles, not chemical reactions.

Momentum Transfer, Not Melting

The process is entirely mechanical at the atomic level. The Argon ions have enough energy to break the atomic bonds holding the target atoms in place, but not enough to melt the bulk material.

The Role of Collision Cascades

When an energetic ion strikes the target, it sets off a chain reaction. The ion collides with a target atom, which then collides with other target atoms in a collision cascade. When this cascade reaches the surface, atoms are ejected if the energy transferred is greater than their surface binding energy.

Key Factors Influencing Efficiency

The process is controlled by several variables. The energy of the bombarding ions, the relative masses of the ions and target atoms, and the binding energy of the target material all determine the sputter yield—the number of atoms ejected per incoming ion.

The Function of Magnets

Many modern systems are magnetron sputtering systems. Magnets are placed behind the target to create a magnetic field that traps the free electrons from the plasma near the target's surface. This dramatically increases the probability of these electrons striking and ionizing Argon atoms, creating a denser, more efficient plasma that increases deposition rates.

Common Pitfalls and Trade-offs

Sputtering is a powerful technique, but it involves clear trade-offs compared to other deposition methods.

Advantage: Material Versatility

Because it is a physical and not a thermal process, sputtering can be used to deposit almost any material, including metals, ceramics, and complex alloys, without altering their composition.

Advantage: Film Quality and Adhesion

The sputtered atoms arrive at the substrate with significant kinetic energy. This results in films that are very dense, well-adhered, and have excellent uniformity and purity.

Disadvantage: Slower Deposition Rates

Compared to thermal evaporation, sputtering is generally a slower process. This can make it less suitable for applications requiring very thick coatings on a mass-production scale.

Disadvantage: System Complexity and Cost

Sputtering systems require a high-vacuum environment, high-voltage power supplies, and precise gas flow control. This makes the equipment more complex and expensive than some alternative methods.

Applying Sputtering to Your Goal

Choosing sputtering depends entirely on the specific properties you need in your final thin film.

- If your primary focus is precision and control: Sputtering offers atomic-level control over film thickness and uniformity, making it ideal for optics and semiconductors.

- If your primary focus is film purity and density: The high-vacuum environment and energetic deposition ensure the creation of high-purity, dense films with strong adhesion.

- If your primary focus is depositing complex alloys: Sputtering transfers the target material's composition directly to the substrate, preserving the stoichiometry of complex materials.

Understanding this process of controlled, atomic-scale construction is the first step toward engineering materials with precisely tailored properties.

Summary Table:

| Key Component | Role in the Process |

|---|---|

| Vacuum Chamber | Creates a contaminant-free environment for deposition. |

| Target (Cathode) | The source material that is bombarded to release atoms. |

| Substrate (Anode) | The surface where the thin film is deposited. |

| Argon Gas | Ionized to create the plasma that bombards the target. |

| High Voltage | Ignites and sustains the plasma for the sputtering process. |

Ready to Engineer Superior Thin Films?

Plasma sputtering is key to creating high-purity, uniform coatings for demanding applications in R&D and manufacturing. KINTEK specializes in high-performance lab equipment, including sputtering systems, to meet your precise deposition needs.

Let's achieve your material science goals together. Contact our experts today to discuss your project and find the ideal solution.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is plasma activated chemical vapor deposition? Enable Low-Temperature Thin Film Deposition

- What is plasma CVD? Unlock Low-Temperature Thin Film Deposition for Sensitive Materials