Plate freezing in an ultra-low temperature (ULT) freezer is a method that achieves rapid cooling through direct physical contact. Unlike standard freezers that cool samples with cold air, a plate freezer uses two refrigerated plates that sandwich the specimen, pulling heat out directly and efficiently through conduction.

Plate freezing offers exceptionally fast and uniform temperature reduction by using direct conduction. However, this speed and efficiency come at the cost of versatility, making it a specialized tool for specific applications rather than a general-purpose storage solution.

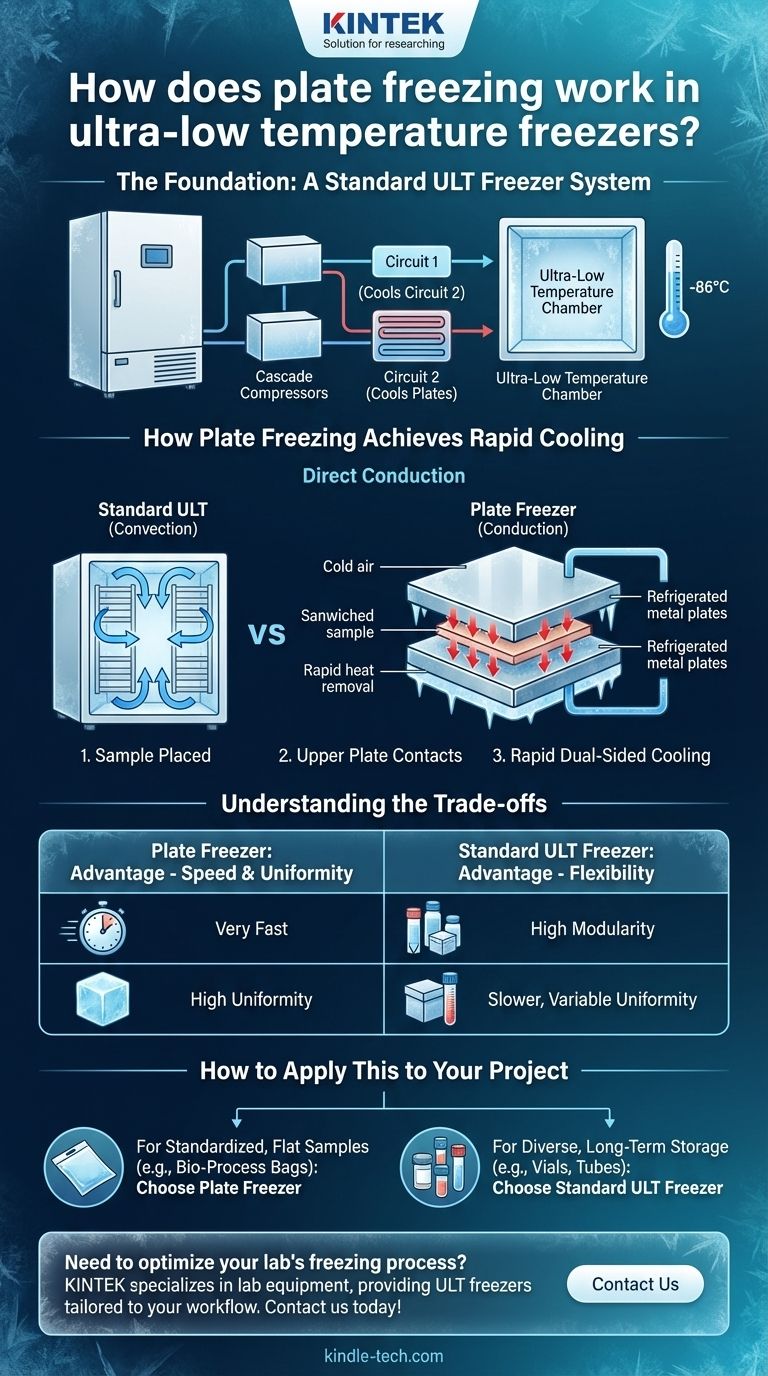

The Foundation: A Standard ULT Freezer System

Before understanding the specific plate mechanism, it's essential to recognize that it operates within the framework of a standard ULT freezer. These systems create the extreme cold necessary for any freezing method.

The Role of Cascade Compressors

Most ULT freezers reach temperatures of -80°C or lower using a cascade refrigeration system. This involves two separate cooling circuits.

The first circuit cools the second, allowing the refrigerant in the second circuit to condense at a much lower temperature than it otherwise could. This multi-stage process is what enables the system to achieve and maintain such extreme cold.

System Integrity and Temperature Control

The entire system is housed in a robust, heavily insulated cabinet with tightly sealed doors. This construction minimizes thermal leakage.

Precise temperature sensors and control algorithms constantly monitor the internal climate, activating the compressors as needed to hold the temperature steady, often within a single degree of the set point (e.g., -86°C).

How Plate Freezing Achieves Rapid Cooling

Plate freezing is a specific method of heat exchange inside the freezer chamber. The cascade system cools the plates, and the plates, in turn, freeze the sample.

The Principle of Direct Conduction

The core mechanism is conduction. Think of placing your hand on a block of ice versus standing in a cold room. The ice chills your hand instantly through direct contact (conduction), while the cold air in the room cools you more slowly (convection).

Plate freezers leverage this principle by bringing the samples into direct contact with metal plates that are actively refrigerated by the freezer's cooling system.

The Freezing Process in Action

A sample, typically in a flat format like a bio-process bag, is placed directly on the lower plate. The upper plate is then lowered to make contact with the top of the sample.

Heat is rapidly pulled from both sides of the sample into the cold plates, resulting in a much faster and more uniform freeze compared to relying on cold air circulation alone.

Understanding the Trade-offs

Choosing a plate freezer involves a clear trade-off between speed and flexibility. It is not a universally superior solution, but rather a specialized instrument for a specific job.

Advantage: Speed and Uniformity

Because conduction is a highly efficient mode of heat transfer, plate freezers can reduce sample temperature far more quickly than convection-based systems. This rapid, dual-sided cooling also promotes freezing uniformity throughout the sample, which is critical for preserving cell viability.

Disadvantage: Lack of Modularity

The primary drawback is a lack of flexibility. Standard ULT freezers use racks and boxes to accommodate a wide variety of sample formats, from small cryovials to microplates.

Plate freezers are designed for a specific geometry—typically flat items. They cannot accommodate the diverse inventory of a typical research lab without significant inefficiency or incompatibility.

Disadvantage: Specialized Application

This lack of modularity makes plate freezers a specialized tool. They excel in process-driven environments where the same type of sample (like bags of media or cell therapies) must be frozen consistently and quickly. They are less suitable for general, long-term archival storage of varied samples.

How to Apply This to Your Project

Your decision should be guided by your primary operational goal—speed and consistency for a specific format, or flexibility for a diverse inventory.

- If your primary focus is rapid, uniform freezing of standardized, flat samples (like bio-process bags): A plate freezer is the ideal choice, as its conductive heat transfer is purpose-built for this task.

- If your primary focus is versatile, long-term storage of diverse sample types (vials, boxes, tubes): A traditional convection or cold-wall ULT freezer provides the essential modularity and racking flexibility you need.

Ultimately, aligning the freezing technology with your specific sample type and workflow is the key to ensuring both operational efficiency and sample integrity.

Summary Table:

| Feature | Plate Freezer | Standard ULT Freezer |

|---|---|---|

| Cooling Method | Direct conduction via refrigerated plates | Convection (cold air circulation) |

| Freezing Speed | Very Fast | Slower |

| Sample Uniformity | High | Variable |

| Flexibility | Low (optimized for flat formats) | High (accommodates vials, tubes, boxes) |

| Ideal Use Case | Process-driven freezing of standardized samples (e.g., cell therapies) | General, long-term storage of diverse samples |

Need to optimize your lab's freezing process? KINTEK specializes in lab equipment and consumables, providing ultra-low temperature freezers tailored to your specific workflow. Whether you require the rapid, uniform freezing of a plate freezer or the flexible storage of a standard ULT model, our experts can help you select the right solution to ensure sample integrity and maximize efficiency. Contact us today to discuss your laboratory needs!

Visual Guide

Related Products

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 938L Vertical Ultra Low Temperature Freezer for Advanced Laboratory Storage

- 808L Precision Laboratory Vertical Ultra Low Temperature Freezer

People Also Ask

- How does fast temperature recovery benefit ultra-low freezers? Protect Sample Integrity and Lab Efficiency

- What features do ultra-low temperature freezers typically include? Ensuring Absolute Sample Security

- What are ultra-low temperature freezers designed for? Preserving Your Most Valuable Biological Samples

- What are the key features to look for in an ultra-low temperature freezer for mRNA vaccine storage? Essential Features for Absolute Vaccine Integrity

- How do ultra-low temperature freezers work? Unlocking the Secrets of -86°C Sample Preservation