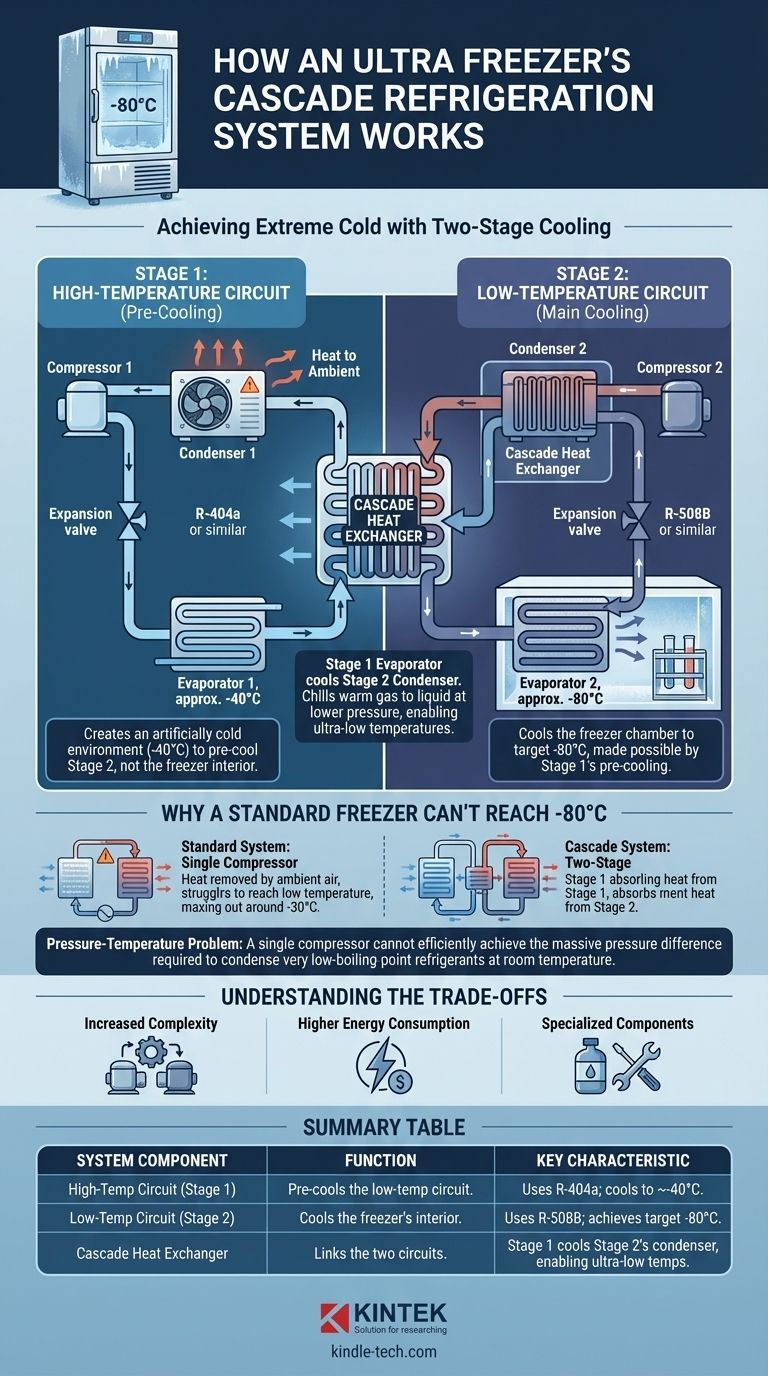

At its core, an ultra freezer achieves extreme cold by using a cascade refrigeration system. This is not a single, powerful cooling circuit like in a household refrigerator, but two distinct refrigeration circuits working together. One circuit's primary job is to pre-cool the other, allowing the second circuit to reach temperatures far lower than any single system could.

The fundamental challenge in reaching ultra-low temperatures isn't just making something cold; it's removing heat effectively when the ambient temperature is comparatively warm. A cascade system solves this by using a high-temperature circuit to create an artificially cold environment for a low-temperature circuit to operate in, overcoming the physical limits of a single compressor.

Why a Standard Freezer Can't Reach -80°C

A standard refrigeration system works by compressing a gas, which heats it up, then cooling it back down into a liquid in a condenser. This liquid then expands in an evaporator, becoming intensely cold and absorbing heat. To reach ultra-low temperatures, this cycle is pushed to its limits.

The Pressure-Temperature Problem

For a refrigerant gas to turn back into a liquid in the condenser, it must be cooled and pressurized. The colder you want the freezer to be, the lower the refrigerant's boiling point must be, which in turn means it requires extremely high pressure to force it to condense at room temperature.

A single compressor simply cannot generate this massive pressure difference efficiently or reliably.

The Cascade System: A Two-Stage Solution

The cascade system overcomes this limitation by splitting the work into two optimized stages, each with its own compressor and specialized refrigerant. Think of it as a relay race for heat removal.

Stage 1: The High-Temperature Circuit

The first circuit operates like a powerful, but relatively standard, freezer. It uses a refrigerant designed for higher temperatures (e.g., R-404a).

Its sole purpose is not to cool the freezer chamber. Instead, its evaporator gets extremely cold (perhaps -40°C) to absorb heat from the second circuit.

Stage 2: The Low-Temperature Circuit

This second circuit is what actually cools the ultra freezer's interior. It uses a specialized low-temperature refrigerant with a very low boiling point (e.g., R-508B).

This circuit's condenser, instead of being cooled by ambient air, is cooled by the evaporator from Stage 1.

The Critical Connection: The Heat Exchanger

The two circuits meet at a component called a cascade heat exchanger. Here, the cold evaporator from Stage 1 chills the warm, compressed gas in the condenser of Stage 2.

By exposing the Stage 2 condenser to a -40°C environment instead of room temperature, its refrigerant can easily turn back into a liquid at a much lower, more manageable pressure. This "super-cooled" liquid can then expand to achieve the target -80°C inside the freezer.

Understanding the Trade-offs

The performance of a cascade system comes with inherent costs that are important to recognize.

Increased Complexity

A cascade system has two compressors, two sets of refrigerants, and two independent cooling loops. This doubles the number of critical components that can fail compared to a standard freezer.

Higher Energy Consumption

Running two compressors consumes significantly more energy than running one. The system is engineered for maximum cooling power, not maximum efficiency.

Specialized Components

The refrigerants used are chosen for their specific thermodynamic properties at extreme temperatures. They require specialized handling and service procedures compared to those in common household appliances.

Making the Right Choice for Your Goal

Understanding the core design of an ultra freezer helps put its capabilities and requirements into perspective.

- If your primary focus is performance: The cascade system's two-stage process is the key technology that overcomes the physical limitations of single-stage cooling to achieve ultra-low temperatures.

- If your primary focus is maintenance or purchasing: Recognize that this performance comes from added complexity—two compressors and two circuits—which translates to higher energy use and more potential failure points.

By breaking the problem of extreme heat removal into two manageable stages, the cascade system provides a robust and effective engineering solution for ultra-low temperature storage.

Summary Table:

| System Component | Function | Key Characteristic |

|---|---|---|

| High-Temp Circuit (Stage 1) | Pre-cools the low-temp circuit. | Uses refrigerant like R-404a; cools to ~-40°C. |

| Low-Temp Circuit (Stage 2) | Cools the freezer's interior. | Uses refrigerant like R-508B; achieves target -80°C. |

| Cascade Heat Exchanger | Links the two circuits. | Stage 1 cools Stage 2's condenser, enabling ultra-low temperatures. |

Need reliable ultra-low temperature storage for your lab?

KINTEK specializes in high-performance lab equipment, including ultra-freezers with robust cascade refrigeration systems. We understand the critical need for precise temperature control in preserving sensitive samples, reagents, and vaccines.

Our experts can help you select the right equipment for your specific requirements, ensuring your research and storage goals are met with unwavering reliability. Let us provide a solution that protects your valuable work.

Contact KINTEK today to discuss your laboratory's ultra-freezer needs!

Visual Guide

Related Products

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 208L Advanced Precision Laboratory Ultra Low Temperature Freezer for Cold Storage

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 608L Essential Laboratory Ultra Low Temperature Freezer For Critical Sample Preservation

People Also Ask

- How do ultra-low temperature freezers achieve such low temperatures? The Science Behind -80°C Cooling

- What temperature ranges are typically associated with ultra-low temperature freezers? Preserve Samples from -40°C to -86°C

- What are the recommendations for storing mRNA vaccines in ultra-low temperature freezers? Ensure Absolute Stability at -80°C

- What is the role of an ultra-low temperature (ULT) freezer in the freeze-thaw synthesis of hydrogel nanocomposites?

- How does fast temperature recovery benefit ultra-low freezers? Protect Sample Integrity and Lab Efficiency