The seal of an ultra-low temperature (ULT) freezer is a critical line of defense for your samples. It is a gasket positioned along the perimeter of the cabinet that creates a physical barrier when the door is closed. By preventing the exchange of air between the freezer's interior and the outside room, a high-quality seal directly maintains temperature stability, reduces frost buildup, and lowers the operational strain on the entire system.

The effectiveness of a ULT freezer's seal isn't just about keeping the door shut; it's about creating a near-perfect barrier against the outside environment. A superior seal directly translates to greater temperature stability, lower energy consumption, and ultimately, better protection for irreplaceable biological samples.

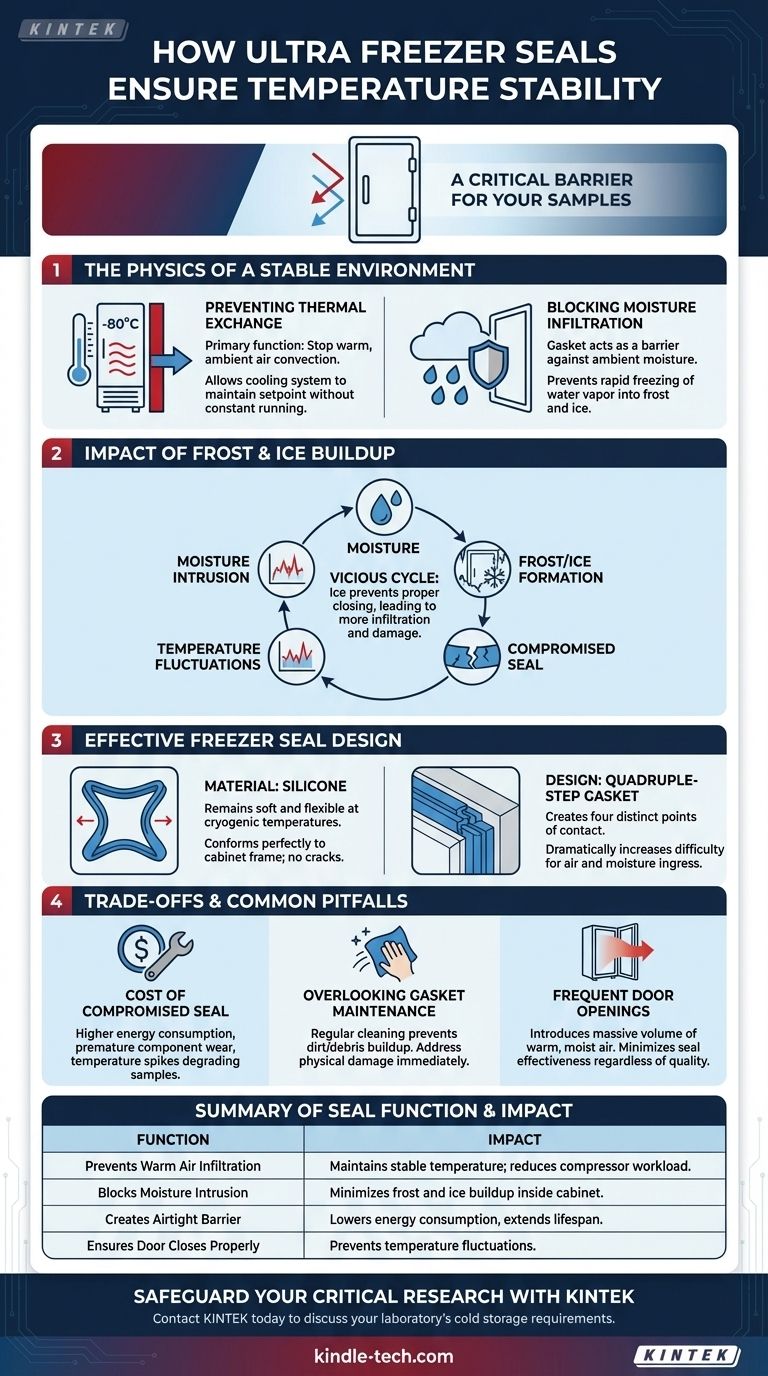

The Physics of a Stable Ultra-Low Environment

To appreciate the seal's role, you must understand the constant battle a ULT freezer fights against its surroundings. The extreme temperature differential creates immense pressure for thermal and atmospheric exchange.

Preventing Thermal Exchange

The primary function of the seal is to prevent warm, ambient air from entering the freezer cabinet. This process, known as convection, is the most significant source of heat gain.

A tight seal stops this infiltration, allowing the cooling system to maintain its setpoint (e.g., -80°C) without constantly running to combat incoming warmth.

Blocking Moisture Infiltration

Ambient air contains moisture. When this moist air enters a ULT freezer, the water vapor rapidly freezes, forming frost and ice on interior surfaces.

The gasket acts as the first and most important barrier against this moisture intrusion, which is a persistent threat to freezer performance.

The Impact of Frost and Ice Buildup

Frost and ice are highly detrimental. Ice buildup on or around the gasket can prevent the door from closing properly, compromising the seal itself.

This creates a vicious cycle: a poor seal allows more moist air in, which creates more ice, which further damages the seal's integrity and causes significant temperature fluctuations.

What Defines an Effective Freezer Seal?

Not all seals are created equal. The most effective designs are a result of careful material science and engineering that account for the extreme conditions inside a ULT freezer.

Material: The Role of Silicone

Silicone is the material of choice for high-performance gaskets. Unlike rubber or other plastics, it remains soft and flexible even at cryogenic temperatures.

This flexibility is essential for the gasket to conform perfectly to the cabinet frame every time the door is closed, preventing cracks or brittleness that would create air leaks.

Design: The Quadruple-Step Gasket

The most efficient models often feature a quadruple-step gasket. This design creates four distinct points of contact between the door and the cabinet.

Think of it as having four seals in one. Each "step" creates an additional barrier, dramatically increasing the difficulty for air and moisture to find a path into the freezer.

Understanding the Trade-offs and Common Pitfalls

A freezer's seal is a common point of failure, and overlooking its importance has direct consequences for both your samples and your budget.

The Cost of a Compromised Seal

A damaged or ineffective seal forces the freezer's compressors to work much harder and more frequently to maintain temperature.

This leads to significantly higher energy consumption and premature wear on critical components, shortening the freezer's operational lifespan. Most importantly, it causes temperature spikes that can degrade sensitive biological samples.

Overlooking Gasket Maintenance

Gaskets are not "set and forget" components. Over time, they can accumulate dirt, debris, or residue that prevents a tight seal.

Regularly wiping down the gasket with a soft cloth and an appropriate cleaning agent is a simple but critical maintenance step that is often overlooked. Physical damage, like rips or tears, must be addressed immediately.

The Problem with Frequent Door Openings

Even the world's best seal is rendered useless when the door is open. Each opening introduces a massive volume of warm, moist air that the system must then work to remove.

Poor inventory management that requires long or frequent door openings is a major contributor to temperature instability and ice buildup, regardless of seal quality.

Making the Right Choice for Your Goal

The integrity of your freezer seal is directly tied to the integrity of your samples. Applying this understanding is key to reliable cold storage.

- If your primary focus is purchasing a new freezer: Prioritize models with multi-step silicone gaskets and heated door frames to ensure maximum temperature stability and efficiency from day one.

- If your primary focus is maintaining an existing freezer: Regularly inspect the gasket for cracks, dirt, or ice, and clean it according to the manufacturer's guidelines to ensure a perfect seal.

- If your primary focus is preserving sensitive samples: Minimize door opening times and always ensure the door is securely latched after every use to prevent preventable thermal fluctuations.

Ultimately, treating the freezer seal as an active component of your cold storage strategy is fundamental to safeguarding your research.

Summary Table:

| Function of the Seal | Impact on Freezer Performance |

|---|---|

| Prevents Warm Air Infiltration | Maintains stable temperature; reduces compressor workload |

| Blocks Moisture Intrusion | Minimizes frost and ice buildup inside the cabinet |

| Creates an Airtight Barrier | Lowers energy consumption and extends equipment lifespan |

| Ensures Door Closes Properly | Prevents temperature fluctuations that can damage samples |

Safeguard your critical research with reliable cold storage solutions from KINTEK.

Your samples are irreplaceable. A high-performance ultra-low temperature freezer with a superior seal is essential for maintaining temperature stability, ensuring sample integrity, and reducing operational costs. KINTEK specializes in providing high-quality lab equipment, including ULT freezers, to meet the precise needs of research laboratories.

Let our experts help you select the right equipment to protect your work. Contact KINTEK today to discuss your laboratory's cold storage requirements.

Visual Guide

Related Products

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 28L Compact Upright Ultra Low Temperature Freezer for Laboratory

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 808L Precision Laboratory Vertical Ultra Low Temperature Freezer

- 208L Advanced Precision Laboratory Ultra Low Temperature Freezer for Cold Storage

People Also Ask

- How do ultra-low temperature freezers work? Unlocking the Secrets of -86°C Sample Preservation

- How should frost be removed from Ultra-Low Temperature Freezers? Protect Your Samples and Equipment

- Why are ultra-low temperature freezers important in scientific research? Ensure Sample Integrity and Reproducibility

- What types of materials are commonly stored in ultra low temperature freezers? Preserving Cells, Vaccines & Biomolecules

- Why are ULT freezers considered vital equipment in labs? Ensuring Uncompromised Sample Integrity for Critical Research