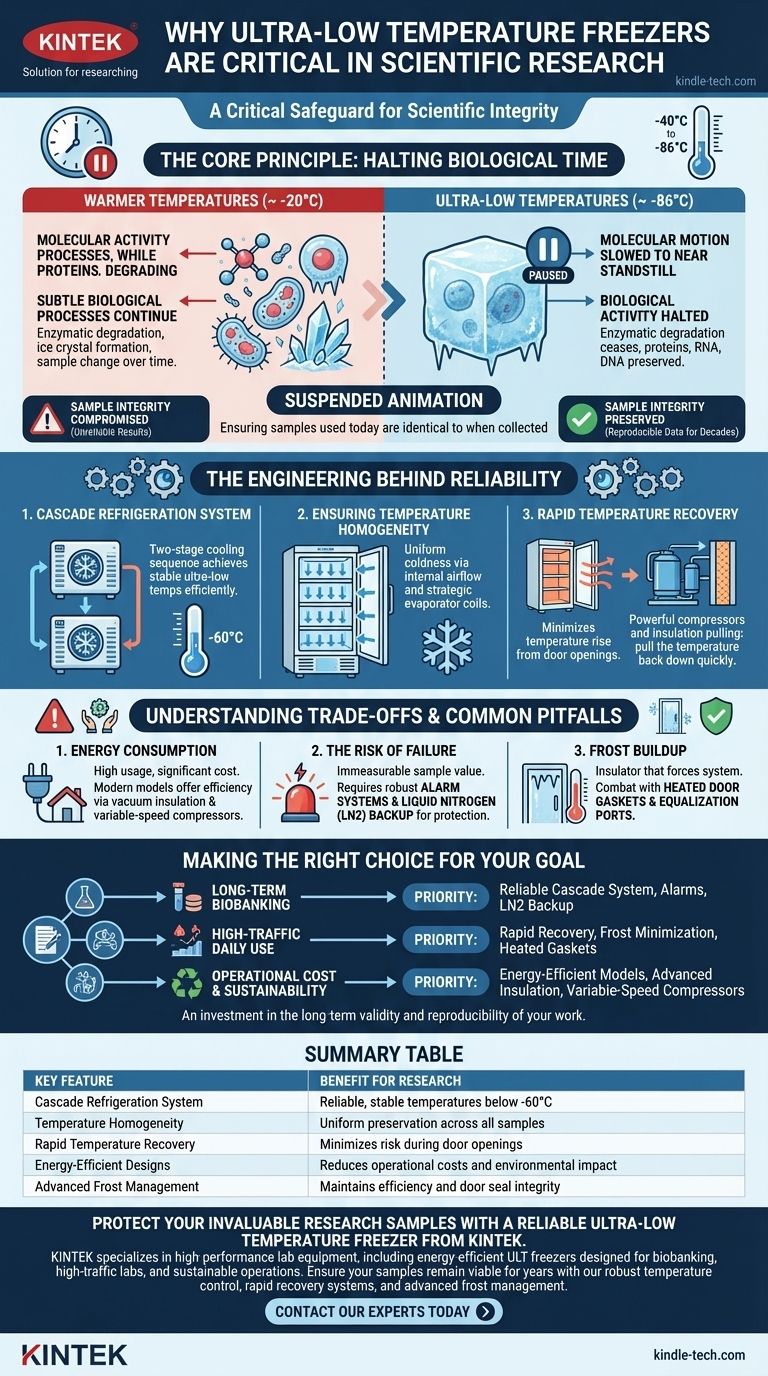

At its core, an ultra-low temperature (ULT) freezer is a critical safeguard for scientific integrity. It provides an extremely cold, stable environment, typically -40°C to -86°C, that effectively halts biological and chemical activity. This preserves the original state of invaluable samples like DNA, vaccines, and tissues, ensuring they remain viable and unchanged for long-term research.

The central challenge in modern research is ensuring that samples used for discovery today are identical to how they were when first collected, sometimes years or decades earlier. A ULT freezer is not merely a storage unit; it is a precision instrument designed to create a state of suspended animation, guaranteeing the reproducibility and validity of scientific work over time.

The Core Principle: Halting Biological Time

To understand the importance of a ULT freezer, you must first understand what happens to biological materials when they are not kept at ultra-low temperatures. Time is the enemy of sample integrity.

What Happens at Warmer Temperatures?

Even at standard freezer temperatures (around -20°C), subtle biological processes continue. Enzymes can slowly degrade key molecules, ice crystals can form and damage cellular structures, and delicate chemical bonds can break down.

Over weeks, months, or years, these changes accumulate. A sample stored improperly is no longer the same sample that was collected, rendering any experimental results based on it unreliable or invalid.

How Ultra-Low Temperatures Create Stability

At temperatures approaching -86°C, molecular motion is slowed to a near standstill. This effectively pauses the clock on biological activity.

Enzymatic degradation ceases, preventing the breakdown of proteins, RNA, and DNA. This state of stasis ensures that a sample analyzed a decade from now will yield the same data as it would have on the day it was stored, which is the foundation of longitudinal studies and biobanking.

The Engineering Behind Reliability

A ULT freezer is a highly engineered device designed for one purpose: unwavering stability. Several key technologies work in concert to achieve and maintain these extreme temperatures reliably.

The Cascade Refrigeration System

Most high-performance ULT freezers use a cascade refrigeration system. This is essentially two refrigeration systems working in a sequence.

The first system cools a heat exchanger to an intermediate temperature. The second system uses this pre-chilled exchanger to cool its own refrigerant, allowing it to achieve the final, ultra-low temperature inside the chamber. This two-stage approach is far more efficient and reliable for reaching temperatures below -60°C than a single, high-power compressor.

Ensuring Temperature Homogeneity

It is not enough for the freezer to be cold; it must be uniformly cold. Temperature variations between the top and bottom shelves can lead to inconsistent sample preservation.

ULT freezers achieve temperature homogeneity through features like internal shelving that promotes airflow and the strategic placement of evaporator coils within the walls. This ensures all samples experience the same stable environment, regardless of their position.

Rapid Temperature Recovery

Every time the freezer door is opened, warm, moist air enters, causing the internal temperature to rise. A critical performance metric is temperature recovery—the time it takes to return to the setpoint.

Powerful compressors, robust insulation, and inner doors for individual compartments work together to minimize the impact of door openings and pull the temperature back down quickly, protecting all samples within.

Understanding the Trade-offs and Common Pitfalls

While essential, ULT freezers are complex instruments with operational considerations that must be managed. Understanding these trade-offs is key to their successful deployment.

Energy Consumption

ULT freezers are energy-intensive devices, often consuming as much electricity as a small house. This is a significant operational cost and environmental consideration. Modern models have made great strides in efficiency with vacuum-insulated panels and variable-speed compressors that adjust to demand.

The Risk of Failure

The value of the samples stored in a single ULT freezer can be immeasurable, representing decades of work. A mechanical or power failure can be catastrophic.

For this reason, robust alarm systems that monitor temperature, power, and door status are non-negotiable. Many labs also implement 24/7 remote monitoring and have liquid nitrogen (LN2) backup systems that can maintain temperature during an extended outage.

Frost Buildup: The Silent Threat

Frost is the enemy of efficiency and stability. It acts as an insulator, forcing the refrigeration system to work harder to maintain temperature. It can also create a poor seal around the door, leading to further temperature fluctuations.

High-quality ULT freezers combat this with features like heated door gaskets and heated pressure equalization ports that prevent ice from forming and ensure the door remains easy to open and seals tightly.

Making the Right Choice for Your Goal

Selecting a ULT freezer requires matching the unit’s features to the specific demands of your research.

- If your primary focus is long-term biobanking: Prioritize a reliable cascade refrigeration system, comprehensive alarm capabilities, and compatibility with a backup system like LN2.

- If your primary focus is high-traffic daily use: Emphasize rapid temperature recovery rates and features that minimize frost, such as heated gaskets and inner doors.

- If your primary focus is operational cost and sustainability: Seek out modern, energy-efficient models with advanced vacuum insulation and variable-speed compressors to reduce electricity usage.

Ultimately, a ULT freezer is an investment in the long-term validity and reproducibility of your scientific work.

Summary Table:

| Key Feature | Benefit for Research |

|---|---|

| Cascade Refrigeration System | Reliable, stable temperatures below -60°C |

| Temperature Homogeneity | Uniform preservation across all samples |

| Rapid Temperature Recovery | Minimizes risk during door openings |

| Energy-Efficient Designs | Reduces operational costs and environmental impact |

| Advanced Frost Management | Maintains efficiency and door seal integrity |

Protect your invaluable research samples with a reliable ultra-low temperature freezer from KINTEK.

KINTEK specializes in high-performance lab equipment, including energy-efficient ULT freezers designed for biobanking, high-traffic labs, and sustainable operations. Ensure your samples remain viable for years with our robust temperature control, rapid recovery systems, and advanced frost management.

Contact our experts today to find the perfect ULT freezer for your laboratory's needs!

Visual Guide

Related Products

- 108L Vertical Ultra Low Temperature ULT Freezer

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 708L Ultra Low Temperature Freezer High Performance Laboratory Freezer

- 208L Advanced Precision Laboratory Ultra Low Temperature Freezer for Cold Storage

People Also Ask

- How are advancements in compressor technology and refrigerant fluids improving ULT freezers? Boost Efficiency & Cut Costs

- What are ultra-low temperature freezers designed for? Preserving Your Most Valuable Biological Samples

- How is temperature controlled in ultra low temperature freezers? A Guide to Stable -80°C Storage

- How does fast temperature recovery benefit ultra-low freezers? Protect Sample Integrity and Lab Efficiency

- What is the purpose of ultra-low temperature (ULT) freezers? Preserve Critical Biological Samples