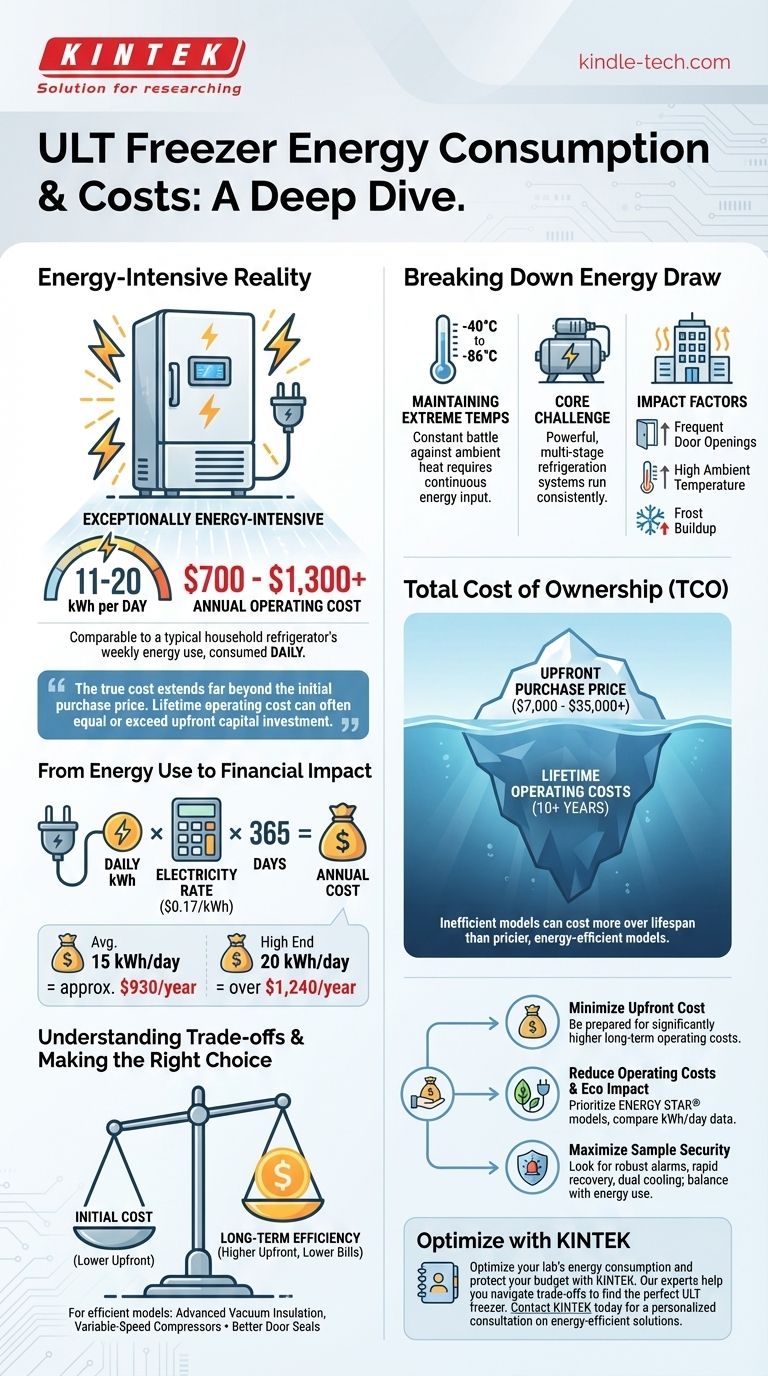

Ultra-low temperature (ULT) freezers are exceptionally energy-intensive, making them one of the most significant sources of electricity consumption in a laboratory. A single ULT freezer typically consumes between 11 and 20 kilowatt-hours (kWh) per day. This translates to an annual operating cost that can easily range from $700 to over $1,300 per unit, based on average electricity rates and usage patterns.

The true cost of a ULT freezer extends far beyond its initial purchase price. Due to high, continuous energy consumption, the lifetime operating cost can often equal or exceed the upfront capital investment, making energy efficiency a critical factor in your purchasing decision.

Breaking Down the Energy Consumption

ULT freezers are designed for a single, demanding task: maintaining extremely low temperatures, often between -40°C and -86°C. This constant battle against ambient room temperature requires a significant and continuous input of energy.

The Core Challenge: Maintaining Extreme Temperatures

The primary driver of energy use is the refrigeration system, which must run consistently to remove heat that inevitably leaks into the insulated cabinet. A powerful cascade refrigeration system, often involving multiple compressors, is required to achieve and hold these ultra-low setpoints.

Quantifying the Daily Draw

As noted, a standard ULT freezer consumes between 11 and 20 kWh per day. To put this in perspective, this is comparable to the energy used by a typical household refrigerator over an entire week, consumed every single day.

A large-scale example from Stanford University in 2010 found that its 2,000+ ULT freezers consumed approximately 40 billion BTUs of energy annually, costing the institution $5.6 million in electricity.

The Impact of Usage and Environment

Real-world energy use is heavily influenced by lab conditions and practices. Factors that increase consumption include:

- Frequent door openings: Allows warm, moist air to enter, forcing the system to work harder.

- High ambient temperature: The warmer the lab, the more energy the freezer needs to reject heat.

- Frost buildup: Ice acts as an insulator, reducing cooling efficiency and forcing the compressor to run longer.

From Energy Use to Total Operating Cost

Understanding the energy draw is the first step; translating it into a financial figure reveals the true long-term impact on your budget.

Calculating Annual Electricity Costs

The operating cost is a simple calculation: daily energy consumption multiplied by your local electricity rate.

Assuming an average electricity rate of $0.17 per kWh, a freezer using 15 kWh/day would cost approximately $930 per year to operate (15 kWh/day x 365 days x $0.17/kWh). For a freezer at the higher end (20 kWh/day), this cost rises to over $1,240 per year.

Factoring in the Upfront Purchase Price

The initial capital investment for a ULT freezer is also substantial, with prices ranging from $7,000 to over $35,000. This price depends on size, features, and brand reputation.

The Total Cost of Ownership (TCO)

When you combine the purchase price with a decade or more of high electricity costs, the total cost of ownership becomes clear. A less expensive, inefficient model could easily cost more over its lifespan than a pricier, energy-efficient model.

Understanding the Trade-offs

Selecting a ULT freezer involves balancing initial cost, long-term performance, and operational efficiency. There is no single "best" choice for every lab.

Initial Cost vs. Long-Term Efficiency

The most significant trade-off is upfront price versus energy consumption. Modern, energy-efficient models may cost more initially but offer substantial savings over the freezer's lifetime through lower electricity bills. Features like advanced vacuum insulation, variable-speed compressors, and better door seals contribute to this efficiency.

Performance vs. Energy Savings

Some units feature an "ECO mode" that reduces energy use by slightly widening the temperature tolerance or adjusting compressor cycles. While this saves energy, it may result in slower temperature recovery after a door opening. For labs with highly sensitive or irreplaceable samples, maximum performance and rapid temperature recovery might be non-negotiable.

Conventional vs. Alternative Cooling

Newer technologies, such as those using liquid nitrogen as a supplemental cooling source instead of relying solely on compressors, claim to reduce energy consumption by as much as 90%. While incredibly efficient, these systems may have different infrastructure requirements and maintenance protocols that must be considered.

Making the Right Choice for Your Lab

Your final decision should be guided by your lab's specific priorities, from budget constraints to scientific needs.

- If your primary focus is minimizing upfront capital expenditure: Be prepared for significantly higher long-term operating costs that may negate the initial savings over the freezer's lifespan.

- If your primary focus is reducing long-term operating costs and environmental impact: Prioritize ENERGY STAR® certified models and carefully compare the manufacturers' published kWh/day consumption data.

- If your primary focus is maximizing sample security: Look for models with robust alarm systems, rapid temperature recovery rates, and dual cooling systems, but balance these features against their documented energy consumption.

By evaluating both the purchase price and the long-term energy consumption, you can make a strategic investment that serves your scientific goals and your budget.

Summary Table:

| Factor | Typical Range/Impact |

|---|---|

| Daily Energy Consumption | 11 - 20 kWh/day |

| Annual Operating Cost | $700 - $1,300+ |

| Upfront Purchase Price | $7,000 - $35,000+ |

| Key Cost Driver | Continuous refrigeration to maintain -40°C to -86°C |

| Factors Increasing Cost | Frequent door openings, high ambient temperature, frost buildup |

Optimize your lab's energy consumption and protect your budget with KINTEK.

Choosing the right ultra-low temperature freezer is a critical decision that impacts your operational costs for years. Our experts at KINTEK specialize in lab equipment and consumables, and we can help you navigate the trade-offs between upfront cost and long-term efficiency to find the perfect ULT freezer for your specific laboratory needs and sample security requirements.

Contact KINTEK today for a personalized consultation to discuss energy-efficient solutions that will reduce your operating expenses and ensure the integrity of your valuable samples.

Visual Guide

Related Products

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 608L Essential Laboratory Ultra Low Temperature Freezer For Critical Sample Preservation

- 708L Ultra Low Temperature Freezer High Performance Laboratory Freezer

- 28L Compact Upright Ultra Low Temperature Freezer for Laboratory

People Also Ask

- What is the purpose of ultra-low temperature (ULT) freezers? Preserve Critical Biological Samples

- What are the key features to look for in an ultra-low temperature freezer for mRNA vaccine storage? Essential Features for Absolute Vaccine Integrity

- What are the recommendations for storing mRNA vaccines in ultra-low temperature freezers? Ensure Absolute Stability at -80°C

- What is the temperature control capability of ultra-low freezers? Precise Stability Down to -86°C

- What temperature ranges are typically associated with ultra-low temperature freezers? Preserve Samples from -40°C to -86°C