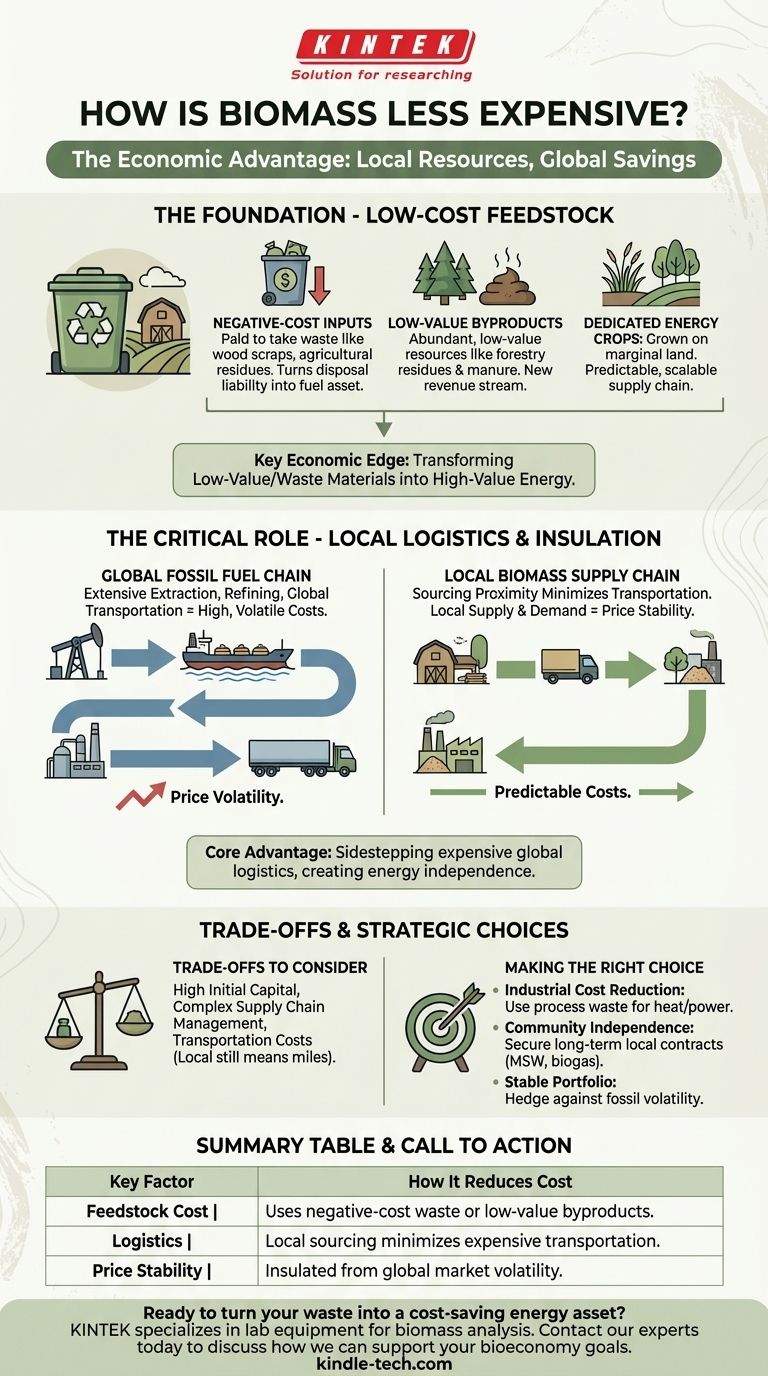

To be direct, biomass is less expensive primarily because its fuel source—the feedstock—is often a low-cost waste product or a locally abundant resource. Unlike fossil fuels, which require extensive extraction, refining, and global transportation, biomass can be sourced from agricultural residues, forestry byproducts, or even municipal solid waste, drastically cutting the raw material and logistics costs that dominate traditional energy pricing.

The core economic advantage of biomass is not inherent to the technology itself, but to its supply chain. Its cost-effectiveness hinges on transforming local, low-value materials or waste streams into high-value energy, sidestepping the volatile and expensive global logistics of fossil fuels.

The Foundation of Biomass Economics: Feedstock Cost

The single largest factor determining the price of biomass energy is the cost of its raw material, or "feedstock." This is where its main competitive edge lies.

Utilizing Negative-Cost Inputs

In many industries, waste disposal is a significant operational expense. Materials like wood scraps from furniture making, sawdust from lumber mills, or agricultural residues like corn stover and nut shells have a "negative cost."

This means businesses often have to pay to have this waste hauled to a landfill. A biomass facility can take this material for free or even be paid to take it, creating an incredibly low, or even negative, fuel cost.

Leveraging Low-Value Byproducts

Many materials aren't technically waste but have very little market value. Think of forestry thinnings (small trees removed to improve forest health) or manure from large-scale farms.

These resources are abundant and have few other economic uses. Converting them to energy provides a new revenue stream from a low-cost, readily available local supply.

Sourcing from Dedicated Energy Crops

A third model involves growing crops specifically for energy, such as switchgrass or poplar trees. While not as cheap as waste streams, these crops can be grown on marginal land that isn't suitable for food production.

This allows landowners to monetize underutilized assets and creates a predictable, though more expensive, feedstock supply.

The Critical Role of Logistics and Location

The cost of biomass is fundamentally tied to geography. Its low energy density compared to coal or oil means that transportation is a major economic constraint.

The Power of Local Sourcing

Biomass facilities are almost always built in close proximity to their feedstock source. A power plant might be located next to a major sawmill, or a biofuel refinery could be situated in the heart of a major agricultural region.

This drastically reduces transportation costs, which are a huge component of the price of globally traded commodities like oil and natural gas.

Insulation from Global Market Volatility

The price of oil is subject to geopolitical events, currency fluctuations, and decisions made by cartels. The price of local biomass, however, is determined by local supply and demand.

This creates price stability and predictability, allowing businesses and communities to better forecast and manage their energy expenses. It offers a powerful form of energy independence.

Understanding the Trade-offs and Nuances

While biomass offers compelling economic advantages, it is not a universally cheap or simple solution. Objectivity requires acknowledging its limitations.

High Initial Capital Investment

Building a biomass conversion plant—whether for heat, power, or biofuels—requires significant upfront capital. The technology for combustion and conversion can be more complex and costly than a standard natural gas furnace or boiler.

The Challenge of Supply Chain Management

Unlike a pipeline that delivers natural gas on demand, a biomass supply chain requires active management. Sourcing, collecting, storing, and processing feedstock is a complex logistical operation.

An inconsistent supply, whether due to seasonal availability or competing uses, can threaten the economic viability of a plant.

The Hidden Costs of Transportation

While local sourcing is key, "local" can still mean driving trucks over dozens of miles. The cost of fuel, vehicle maintenance, and labor for transportation can quickly add up and must be carefully factored into the economic model. The low density of biomass means more truckloads are needed to deliver the same amount of energy as coal or diesel.

Making the Right Choice for Your Goal

The cost-effectiveness of biomass is entirely dependent on your specific situation and objectives.

- If your primary focus is industrial cost reduction: Your best strategy is to utilize your own process waste streams (wood chips, agricultural husks, food waste) to generate heat or power, turning a disposal liability into an energy asset.

- If your primary focus is community energy independence: The economic success of your project will depend on securing long-term contracts for low-cost, local feedstocks like municipal solid waste, wastewater biogas, or forestry residues within a tight radius.

- If your primary focus is creating a stable, predictable energy portfolio: Biomass can serve as an excellent hedge against fossil fuel price volatility, but be prepared for higher upfront capital costs and the operational demands of managing a physical supply chain.

Ultimately, the economic strength of biomass lies in its ability to harness local resources efficiently, turning what others see as waste into a valuable and reliable source of energy.

Summary Table:

| Key Factor | How It Reduces Cost |

|---|---|

| Feedstock Cost | Uses negative-cost waste (e.g., sawdust) or low-value byproducts (e.g., manure). |

| Logistics | Local sourcing minimizes expensive transportation compared to global fossil fuels. |

| Price Stability | Insulated from global market volatility, offering predictable energy pricing. |

Ready to turn your waste into a cost-saving energy asset? KINTEK specializes in lab equipment and consumables for biomass analysis and conversion research. Whether you're developing new biofuels or optimizing feedstock processes, our precise, reliable equipment helps you validate the economic potential of biomass for your specific application. Contact our experts today to discuss how we can support your laboratory's role in the bioeconomy!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Wall Mounted Water Distillation Unit

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Carbon Graphite Plate Manufactured by Isostatic Pressing Method

- Evaporation Boat for Organic Matter

People Also Ask

- What are the advantages of a wiped film evaporator? Purify Heat-Sensitive Materials Without Degradation

- Why are specialized environmental control units necessary for micro-scale testing? Protect Your Data Integrity

- What role does the sintering process play in TiO2 photocatalysts? Optimize Adhesion and Phase Transition

- What is the standard for elemental analysis? A Guide to Accurate, Traceable Results

- How do precision dripping systems or syringes contribute to sodium alginate bead formation? Achieve Scientific Uniformity

- What is the history of spark plasma sintering? From 1930s Origins to Modern FAST Technology

- How does a constant temperature drying oven contribute to Bi2O3/GO thin films? Expert Curing for Superior Adhesion

- What is the importance of a temperature-controlled heating device? Master the Synthesis of 1,3,4-oxadiazole Derivatives