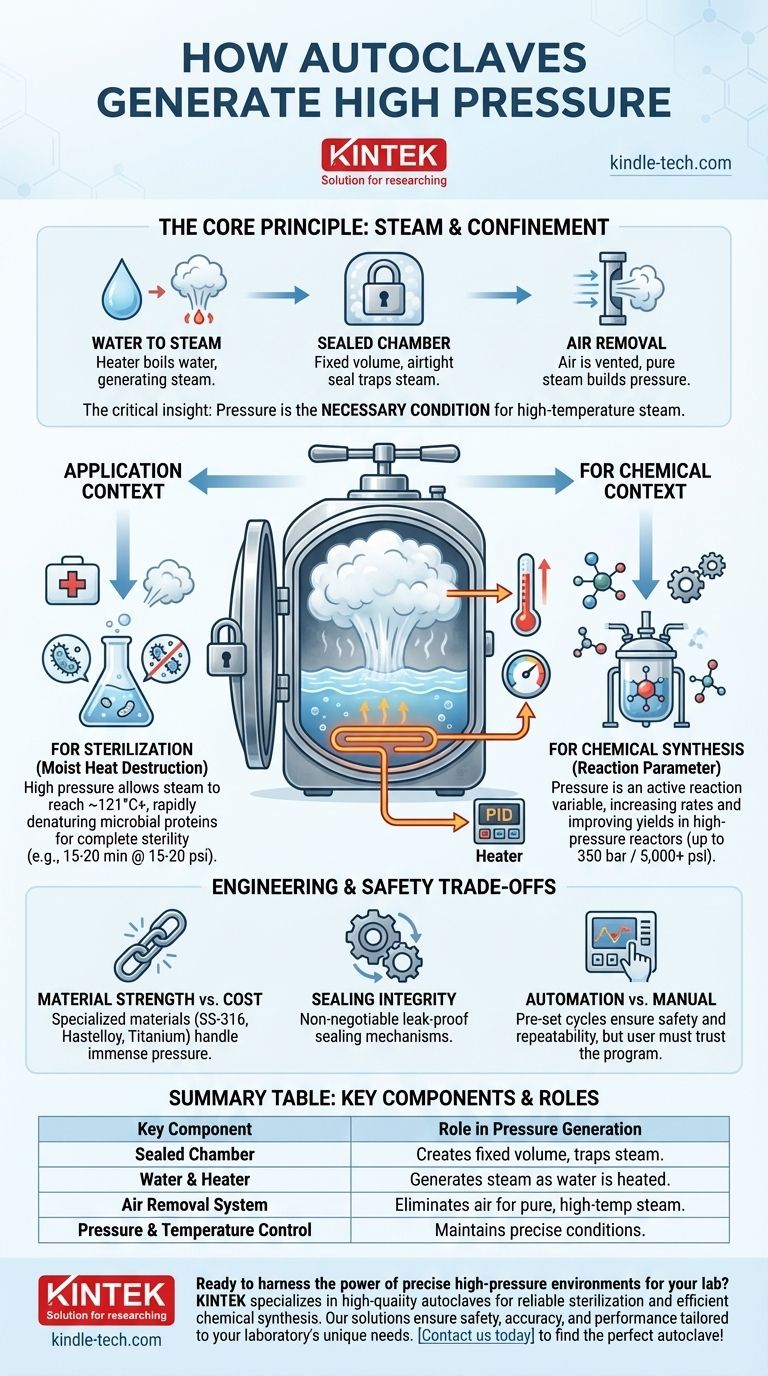

In an autoclave, high pressure is generated by heating water within a perfectly sealed chamber to create steam. Because the steam cannot escape the fixed-volume vessel, its continued generation and rising temperature cause a rapid and predictable increase in internal pressure, a principle governed by the relationship between temperature, volume, and pressure of a gas.

The critical insight is that high pressure is not the goal itself, but rather the necessary condition to achieve a high-temperature steam environment. By pressurizing the system, water can remain as steam at temperatures far exceeding its normal 100°C boiling point, enabling highly efficient heat transfer for sterilization or chemical reactions.

The Core Principle: How Steam Creates Pressure

From Water to Saturated Steam

The process begins with a source of water inside the autoclave's chamber. An electric heater, precisely managed by a PID controller, boils this water to generate steam.

The Sealed Chamber is Key

An autoclave is fundamentally a pressure vessel, engineered to be completely airtight when the door is locked. This sealed environment is the most critical factor in building pressure.

As steam is generated, it fills the chamber's fixed volume. Since the gas has nowhere to escape, any additional steam introduced or any increase in the steam's temperature directly translates into higher internal pressure.

The Role of Air Removal

For the process to be effective, nearly all air must be removed from the chamber. Trapped air acts as an insulator, creating "cold spots" and preventing the superheated steam from making direct contact with the surfaces of the items inside.

This air removal is typically achieved through gravity displacement, where incoming steam (which is less dense than air) pushes the heavier air down and out through a vent, or through a vacuum cycle that actively pumps the air out before steam is introduced.

Why This Pressure Matters: Application Context

For Sterilization: Moist Heat Destruction

In laboratory and medical settings, the goal is sterilization. The high pressure (often around 15-20 psi above atmospheric) allows the steam temperature to reach 121°C or higher.

This high-temperature, moisture-saturated environment is incredibly lethal to microorganisms. It rapidly denatures the essential proteins and enzymes that bacteria, viruses, and spores need to survive, ensuring complete sterility in as little as 15-20 minutes.

For Chemical Synthesis: A Reaction Parameter

In high-pressure reactors used for industrial chemistry, pressure serves a more complex role. It is not just for raising temperature but is often a fundamental parameter of the reaction itself.

For processes like hydrogenation or polymerization, high pressure increases reaction rates, improves yields, and can even determine the final products. The robust construction of these reactors (using materials like Hastelloy or Titanium) allows them to operate at extreme pressures (up to 350 bar or over 5,000 psi) and temperatures.

Understanding the Engineering and Safety Trade-offs

Material Strength vs. Cost

The ability to withstand immense pressure and high temperatures requires specialized materials like SS-316 stainless steel, Hastelloy, or even Titanium. These materials are expensive and difficult to machine, representing a primary cost driver in autoclave design.

Sealing Integrity is Non-Negotiable

A failure in the chamber's seal under pressure is catastrophic. Autoclaves employ sophisticated sealing mechanisms, such as automatically locking doors and advanced magnetic drive couplings on reactors, to ensure a perfect, leak-proof seal throughout the entire operational cycle.

Automation vs. Manual Control

Modern autoclaves rely on automated programs controlled via a simple user interface. While this ensures safety and repeatability, it abstracts the underlying physics. Users must trust that the pre-set cycles for pressure, temperature, and time are appropriate for their specific load, as incorrect programming can lead to incomplete sterilization or damaged goods.

Making the Right Choice for Your Goal

Understanding how pressure is generated clarifies its purpose. Whether for a lab, clinic, or industrial plant, the principles remain the same, but the objective differs.

- If your primary focus is sterilization: The goal is to use pressure simply to create a 121°C saturated steam environment, ensuring complete heat penetration and microbial destruction.

- If your primary focus is chemical synthesis: The goal is to use pressure as an active variable to control reaction kinetics, manage reactants, and achieve a desired chemical outcome at elevated temperatures.

Ultimately, generating pressure in an autoclave is about creating a precisely controlled physical environment that is impossible to achieve under normal atmospheric conditions.

Summary Table:

| Key Component | Role in Pressure Generation |

|---|---|

| Sealed Chamber | Creates a fixed volume, trapping steam to build pressure. |

| Water & Heater | Generates steam as water is heated. |

| Air Removal System | Eliminates air to ensure pure, high-temperature steam. |

| Pressure & Temperature Control | Maintains precise conditions for effective sterilization or reactions. |

Ready to harness the power of precise high-pressure environments for your lab? KINTEK specializes in high-quality autoclaves and lab equipment designed for reliable sterilization and efficient chemical synthesis. Our solutions ensure safety, accuracy, and performance tailored to your laboratory's unique needs. Contact us today to find the perfect autoclave for your application!

Visual Guide

Related Products

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Customizable Laboratory High Temperature High Pressure Reactors for Diverse Scientific Applications

People Also Ask

- What environment does a PTFE-lined autoclave provide for TiO2-GQD synthesis? Achieve Superior Nanocomposite Results

- How does a high-pressure hydrothermal autoclave facilitate the synthesis of BiVO4@PANI nanocomposites? Unlock Precision.

- Which critical experimental conditions does a high-pressure autoclave provide? Optimize Mixed Sulfide Leaching

- What is the function of a high-pressure static autoclave in biomass HTL? Optimize Your Biomass Conversion Research

- What is the role of a high-pressure reactor in h-BN magnetic nanocomposite synthesis? Master Precision Deposition