In sputtering, plasma is created by applying a strong electrical voltage to a target material within a low-pressure vacuum chamber that has been backfilled with an inert gas, typically Argon. This voltage accelerates free electrons, which then violently collide with the neutral gas atoms. These collisions are energetic enough to knock electrons off the gas atoms, transforming them into a self-sustaining mixture of positive ions and free electrons known as a plasma.

The core principle is not merely to create a glow discharge, but to use electrical energy to manufacture a controlled cloud of high-energy ions. This plasma then serves as the medium to bombard a target, effectively acting as an atomic-scale sandblaster to eject coating material onto a substrate.

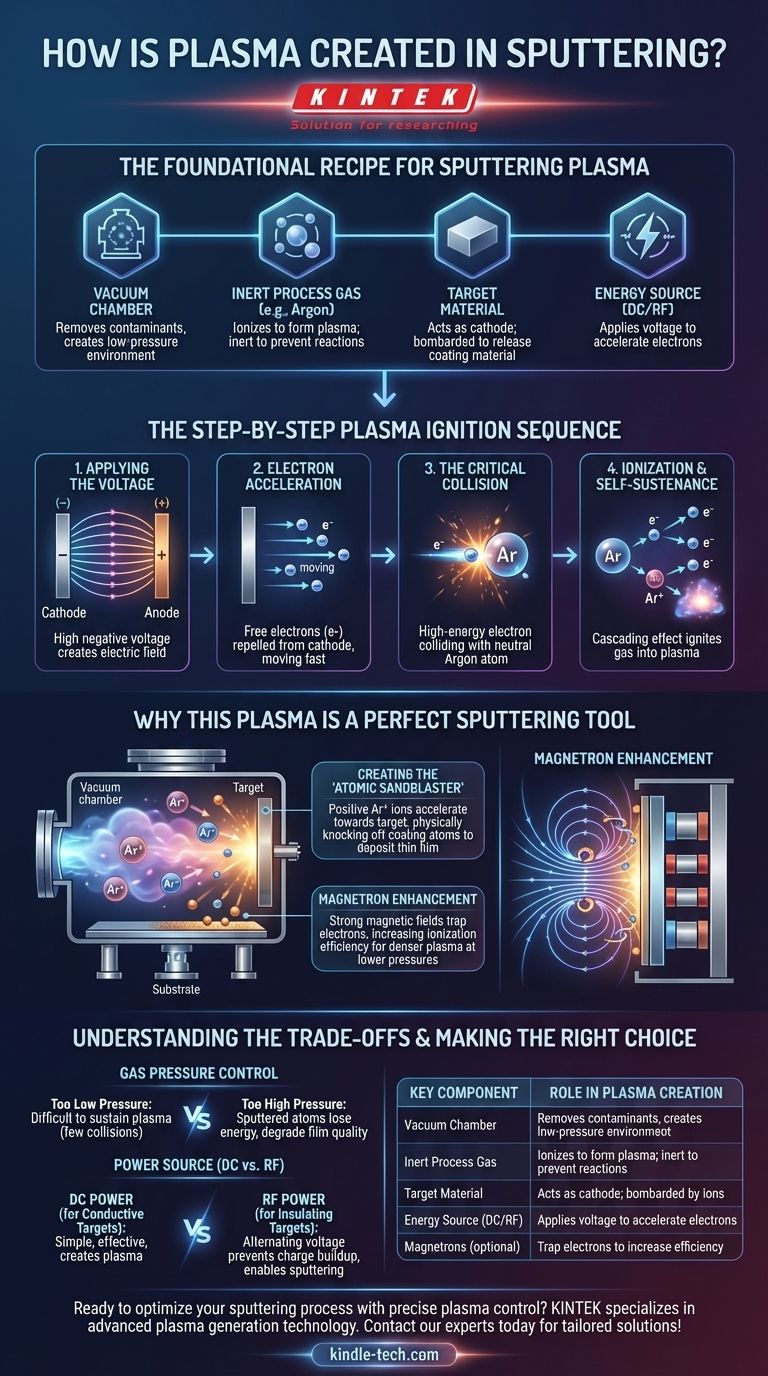

The Foundational Recipe for Sputtering Plasma

Creating a stable and effective plasma for sputtering requires a precise combination of four key ingredients. Each component plays a non-negotiable role in initiating and sustaining the process.

The Vacuum Chamber

The entire process begins by evacuating a sealed chamber to a high vacuum. This initial step is critical for removing atmospheric contaminants like oxygen and water vapor, which would otherwise interfere with the deposition and contaminate the resulting thin film.

The Inert Process Gas

Once a vacuum is established, the chamber is backfilled with a small, controlled amount of a process gas. Argon is the most common choice because it is chemically inert, preventing unwanted reactions, and has a relatively high atomic mass, making it effective at dislodging target atoms upon impact.

The Target Material

The target is a solid slab of the material intended for deposition (e.g., titanium, aluminum, silicon dioxide). It is what the plasma ions will ultimately bombard to create the coating.

The Energy Source

An external power supply, either Direct Current (DC) or Radio Frequency (RF), provides the necessary energy. This source creates a strong electrical potential, typically by making the target the negative electrode (cathode) and the chamber walls or a separate electrode the positive one (anode).

The Step-by-Step Plasma Ignition Sequence

With the foundational elements in place, the creation of the plasma follows a rapid, self-sustaining chain reaction.

Applying the Voltage

A high negative voltage is applied to the target material. This creates a powerful electric field within the chamber.

Electron Acceleration

Any free electrons naturally present in the gas are immediately and violently repelled by the negative target, accelerating across the chamber at high speeds.

The Critical Collision

As these high-energy electrons travel, they collide with the neutral, low-energy Argon atoms filling the chamber.

Ionization and Self-Sustenance

The collision transfers enough energy to knock an electron out of the Argon atom's outer shell. This event creates two new particles: a positively charged Argon ion (Ar+) and another free electron. This new electron is then accelerated by the electric field, leading to more collisions in a cascading effect that rapidly ignites the entire gas into a plasma.

Why This Plasma is a Perfect Sputtering Tool

The plasma is not the end product; it is the tool that makes sputtering possible. Its unique properties are harnessed to achieve atomic-level material transfer.

Creating the "Atomic Sandblaster"

The newly formed positive Argon ions (Ar+) are now strongly attracted to the negatively charged target. They accelerate towards it, striking its surface with significant kinetic energy. This bombardment physically knocks atoms off the target material, "sputtering" them into the chamber where they travel and deposit as a thin film onto a substrate.

The Role of Magnetrons

Modern systems, known as magnetron sputtering systems, place strong magnets behind the target. This magnetic field traps the highly mobile electrons close to the target's surface, forcing them into a spiral path. This greatly increases the probability that an electron will collide with an Argon atom, dramatically improving the ionization efficiency and allowing a dense, stable plasma to be maintained at much lower pressures.

Understanding the Trade-offs

Controlling the plasma is essential for controlling the final film. The process is a balance of competing factors.

Gas Pressure Control

The pressure of the process gas is a critical parameter. If the pressure is too low, there are too few gas atoms for the electrons to collide with, making it difficult to sustain the plasma. If the pressure is too high, the sputtered atoms will collide with too many gas atoms on their way to the substrate, losing energy and potentially degrading film quality.

Power Source (DC vs. RF)

The choice of power source is dictated by the target material. DC power is simple and effective for conductive (metal) targets. However, if the target is an insulating (dielectric) material, positive ions will build up on its surface, neutralizing the negative charge and extinguishing the plasma. RF power rapidly alternates the voltage, preventing this charge buildup and making it possible to sputter any type of material.

Making the Right Choice for Your Goal

Controlling the plasma's creation and properties is how you control the outcome of your coating process.

- If your primary focus is deposition rate: Maximize ion density near the target by using magnetron enhancement and optimizing both gas pressure and power input.

- If your primary focus is film quality: Prioritize a stable plasma by implementing precise control over gas pressure and power, as the plasma's stability directly impacts the energy and uniformity of sputtered atoms.

- If you are sputtering an insulating material: You must use an RF power source to prevent charge accumulation on the target, which is essential to create and sustain the plasma.

Ultimately, mastering the principles of plasma creation is the key to controlling the energy, density, and stability of the entire sputtering process.

Summary Table:

| Key Component | Role in Plasma Creation |

|---|---|

| Vacuum Chamber | Removes contaminants, creates low-pressure environment |

| Inert Process Gas (e.g., Argon) | Ionizes to form plasma; inert to prevent reactions |

| Target Material | Acts as cathode; bombarded by ions to release coating material |

| Energy Source (DC/RF) | Applies voltage to accelerate electrons and ignite plasma |

| Magnetrons (optional) | Trap electrons to increase ionization efficiency at lower pressures |

Ready to optimize your sputtering process with precise plasma control? KINTEK specializes in high-performance lab equipment, including sputtering systems with advanced plasma generation technology. Whether you need DC or RF power sources, magnetron enhancements, or tailored solutions for conductive or insulating materials, we provide the tools to achieve superior thin-film quality and deposition rates. Contact our experts today to discuss how our solutions can enhance your laboratory's capabilities!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- High Performance Laboratory Freeze Dryer

People Also Ask

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells