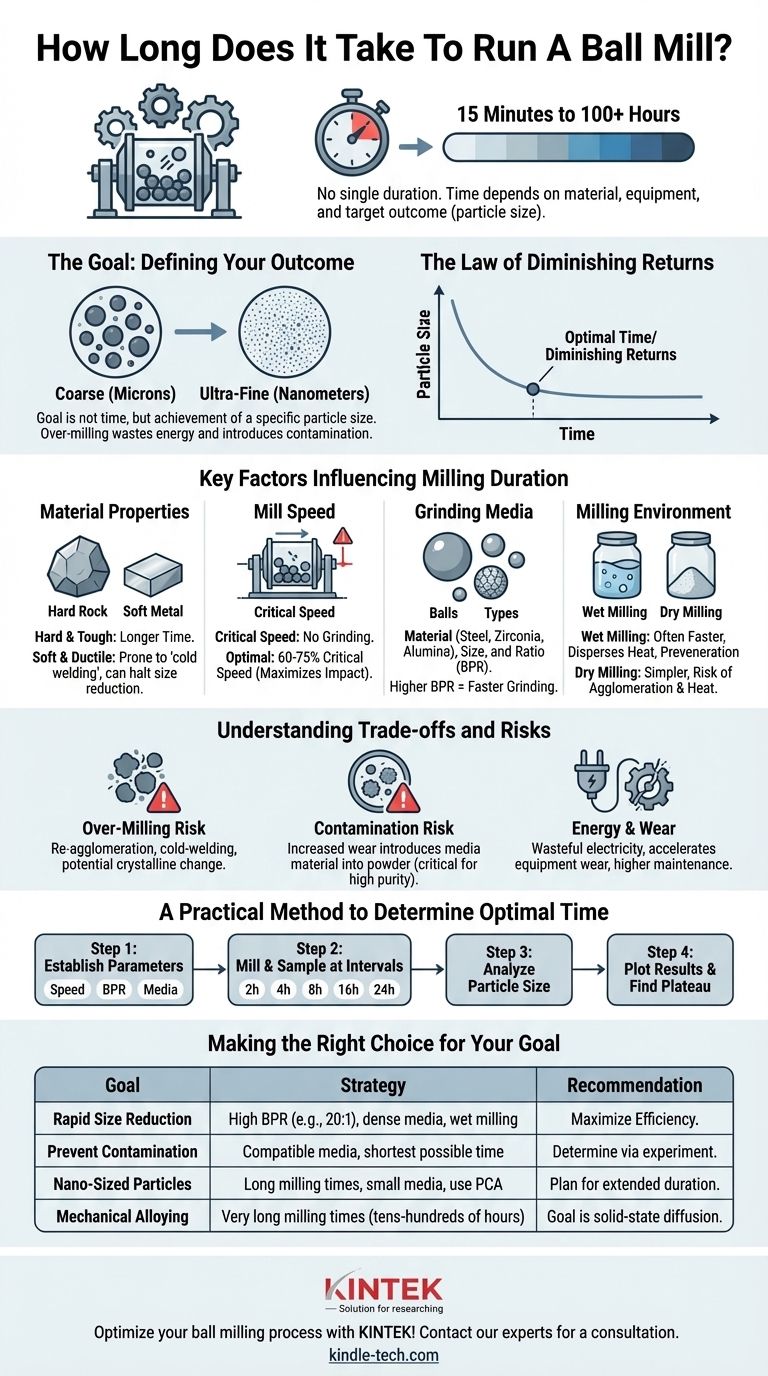

The short answer is this: there is no single duration for running a ball mill. The process can take anywhere from 15 minutes for simple mixing to over 100 hours for creating nano-scale particles or mechanical alloys. The correct time is dictated entirely by your material, your equipment, and most importantly, your desired final particle size.

The goal of ball milling is not to run the mill for a specific time, but to run it just long enough to achieve a specific outcome—usually a target particle size. Extending the time beyond this point yields diminishing returns, introduces contamination, and wastes energy.

The Goal: Defining Your Target Outcome

Before you can determine the milling time, you must first define what you are trying to achieve. The entire process is goal-oriented.

Why Particle Size is the Critical Metric

The duration of milling is almost always determined by the pursuit of a specific particle size. Smaller particles offer a higher surface area, which can increase reaction rates, improve sintering behavior, or create stable suspensions.

Your target might be coarse (microns) or ultra-fine (nanometers), and this single factor will have the largest impact on your milling time.

The Law of Diminishing Returns

The milling process is not linear. Grinding a 1 mm particle down to 100 microns is far faster than grinding a 10-micron particle down to 1 micron.

As particles become smaller, the energy required to fracture them further increases dramatically. At the same time, the tendency for fine particles to clump back together (agglomerate) begins to work against the grinding process.

Key Factors Influencing Milling Duration

Milling time is a function of several interacting variables. Optimizing these factors is the key to reducing your milling time efficiently.

Material Properties: Hardness & Brittleness

Hard, tough materials like tungsten carbide require significantly more energy and time to break down than brittle materials like silicon.

Softer, ductile materials (like aluminum or copper) are prone to "cold welding," where particles flatten and weld together instead of fracturing. This can dramatically increase milling time or even halt size reduction altogether.

Mill Speed: The Concept of Critical Speed

Every mill has a "critical speed"—the rotational speed at which the grinding media are pinned to the wall by centrifugal force and no grinding occurs.

The most effective grinding happens at 60-75% of the critical speed. This maximizes the impact energy as the balls cascade from the top of the jar to the bottom. Running too slow reduces impact force; running too fast prevents it.

Grinding Media: Material, Size, and Ratio

The balls themselves are a critical tool.

- Material: Steel balls are dense and effective but can introduce iron contamination. Zirconia or alumina balls are harder and more inert but less dense, requiring longer times.

- Size: Larger balls are better for breaking down large initial particles. Smaller balls are more efficient for producing very fine final powders.

- Ball-to-Powder Ratio (BPR): This is the weight ratio of the grinding media to your powder. A higher BPR (e.g., 10:1 or 20:1) means more frequent and energetic impacts, leading to faster grinding.

Milling Environment: Wet vs. Dry

Dry milling is simpler but can lead to particle agglomeration and excessive heat.

Wet milling, where a liquid (like ethanol or water) is added, is often more efficient. The liquid disperses heat, prevents particles from clumping together, and can significantly speed up the process of achieving ultra-fine particles.

Understanding the Trade-offs and Risks

Longer is not always better. Understanding the downsides of excessive milling is crucial for process control and quality.

The Risk of Over-Milling

Beyond a certain point, further milling can be counterproductive. Fine particles may begin to re-agglomerate or cold-weld, effectively increasing the particle size. For certain materials, excessive milling can also change the crystalline structure, a process known as amorphization.

The Danger of Contamination

The grinding process is inherently abrasive. The balls and the jar slowly wear down, introducing small amounts of their own material into your powder. The longer you mill, the higher the level of contamination. This is a critical concern in applications requiring high purity, such as pharmaceuticals or electronics.

Energy and Equipment Wear

Ball milling is an energy-intensive process. Running a mill for 100 hours when 20 would have sufficed is a significant waste of electricity and money. It also accelerates the wear and tear on your mill and grinding media, increasing maintenance costs.

A Practical Method to Determine Your Milling Time

The most reliable way to find your optimal time is through a simple, systematic experiment.

Step 1: Establish Your Parameters

Choose your mill speed, ball-to-powder ratio, and media type based on your material and goal. If you are unsure, start with a conservative BPR like 10:1 and a speed of ~70% critical speed.

Step 2: Mill and Sample at Intervals

Run the mill and stop it at predetermined intervals to take a small sample of the powder. A good starting schedule might be to sample at 2, 4, 8, 16, and 24 hours.

Step 3: Analyze Particle Size

Use a particle size analyzer (e.g., laser diffraction) or microscopy (e.g., SEM) to measure the average particle size of each sample.

Step 4: Plot Your Results and Find the Plateau

Create a simple graph with milling time on the x-axis and particle size on the y-axis. You will see a curve where the particle size drops quickly at first and then begins to level off. This "plateau" is your point of diminishing returns. The optimal milling time is typically at the "knee" of this curve, just before it flattens out completely.

Making the Right Choice for Your Goal

Use your target outcome to guide your process development.

- If your primary focus is rapid size reduction: Use a high ball-to-powder ratio (e.g., 20:1), high-density media like steel, and consider wet milling to maximize efficiency.

- If your primary focus is preventing contamination: Select media made of a compatible material (or the same material as your powder) and use the particle size vs. time curve to determine the shortest possible time to reach your goal.

- If your primary focus is achieving nano-sized particles: Plan for long milling times, use small-diameter grinding media, and employ a Process Control Agent (PCA) like stearic acid or a liquid solvent to prevent particle agglomeration.

- If your primary focus is mechanical alloying: Prepare for very long milling times (tens to hundreds of hours) as the goal is to induce solid-state diffusion, not just reduce particle size.

Ultimately, determining the correct milling time is a process of controlled experimentation, not a simple lookup in a table.

Summary Table:

| Key Factor | Influence on Milling Time |

|---|---|

| Target Particle Size | Largest impact; nano-particles require significantly longer times. |

| Material Hardness | Harder, tougher materials (e.g., tungsten carbide) require more time. |

| Ball-to-Powder Ratio (BPR) | Higher BPR (e.g., 20:1) means faster grinding. |

| Milling Environment | Wet milling can speed up the process for ultra-fine particles. |

| Risk of Contamination | Longer times increase contamination from media and jar wear. |

Optimize your ball milling process with KINTEK!

Determining the precise milling time for your specific material and target particle size is critical for efficiency and purity. Whether you are reducing particles to the nano-scale, mechanical alloying, or simply mixing, the right equipment and expert advice make all the difference.

KINTEK specializes in high-quality lab mills, grinding media, and consumables tailored to your laboratory's unique needs. Our experts can help you select the perfect setup to achieve your goals faster and with less contamination.

Don't waste energy and time—Contact our team today for a consultation and let us help you pinpoint your optimal milling parameters!

Visual Guide

Related Products

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- What is the difference between a ball mill and a planetary mill? Choose the Right Grinding Tool for Your Lab

- What is the principle of planetary ball mill? Achieve Rapid, High-Energy Grinding for Your Materials

- What is the difference between a ball mill and a planetary ball mill? Unlock the Right Grinding Technology for Your Lab

- What are the disadvantages of planetary ball mill? Key Drawbacks in Energy, Noise, and Wear

- What are the advantages of planetary ball milling? Achieve High-Energy Grinding and Material Synthesis