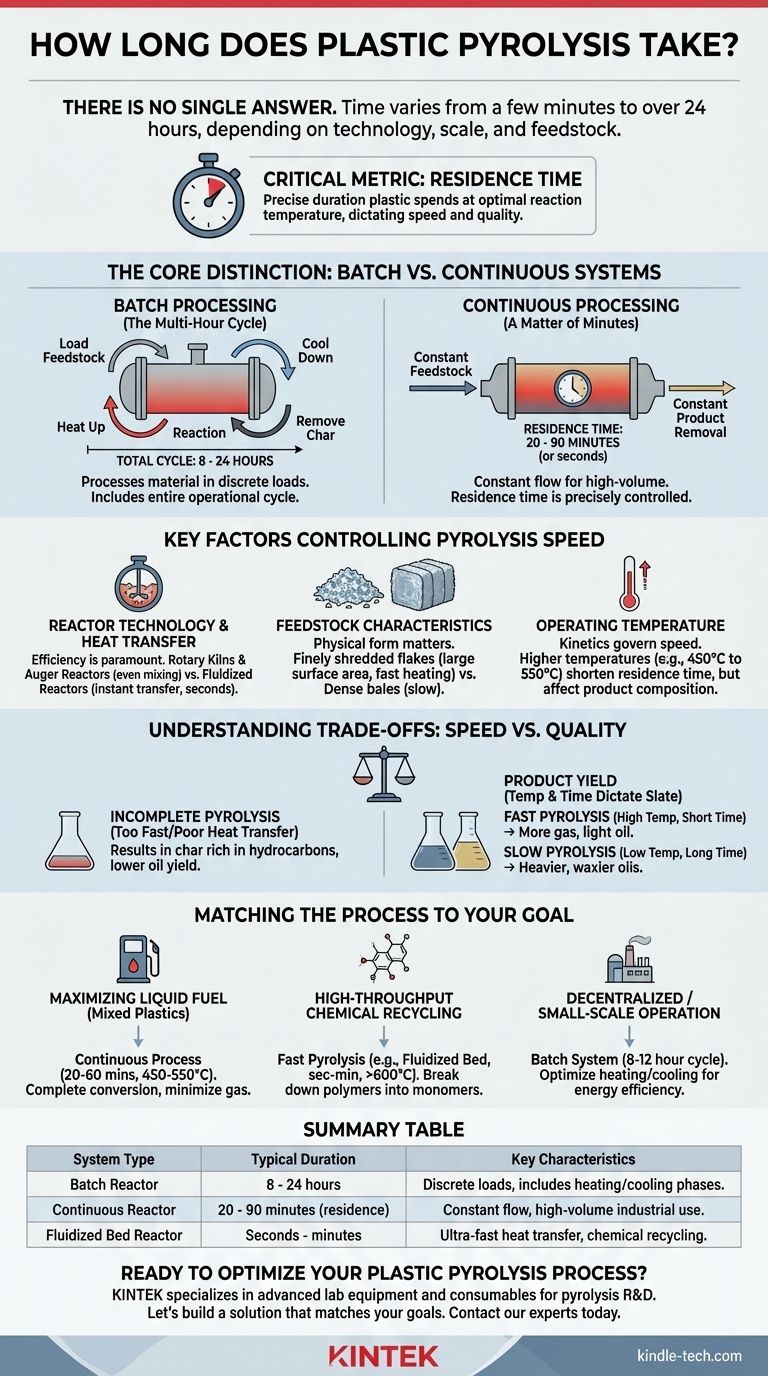

There is no single answer to how long plastic pyrolysis takes, as the time can range from a few minutes to over 24 hours. The duration is not a fixed number but a variable determined entirely by the technology used, the scale of the operation, and the specific characteristics of the plastic being processed. A continuous industrial plant might process plastic in under 30 minutes, while a simpler batch-style reactor will take 8-12 hours to complete a full cycle.

The critical metric is not the total operational time, but the residence time—the precise duration the plastic spends at the optimal reaction temperature. This is dictated by the reactor design and is the key factor that determines both the speed and the quality of the final products.

The Core Distinction: Batch vs. Continuous Systems

The most significant factor influencing pyrolysis duration is the fundamental design of the system: whether it processes material in discrete loads (batch) or in a constant flow (continuous).

Batch Processing: The Multi-Hour Cycle

Batch reactors are loaded with feedstock, sealed, and then heated to the target temperature. The entire volume of plastic is processed at once.

The total operational cycle for a batch system is long, often between 8 to 24 hours. This includes loading, the initial heat-up period, the actual pyrolysis reaction time, a cool-down phase, and finally, the removal of solid residue (char). While the chemical reaction itself might only take a few hours, the entire operational cycle defines the plant's throughput.

Continuous Processing: A Matter of Minutes

Continuous reactors are designed for large-scale industrial applications where feedstock is constantly fed into the system and products are continuously removed.

Here, the critical metric is residence time, which can be precisely controlled. For most continuous plastic pyrolysis systems, this residence time is between 20 and 90 minutes. In highly advanced systems like fluidized bed reactors, it can be as short as a few seconds to a couple of minutes due to exceptionally efficient heat transfer.

Key Factors Controlling Pyrolysis Speed

Beyond the system type, several variables directly control the rate of the pyrolysis reaction. Understanding these is crucial for designing or evaluating a system.

Reactor Technology and Heat Transfer

The efficiency of heat transfer is the most important technical variable. The plastic must be heated uniformly to the core to pyrolyze effectively.

Different reactor designs achieve this with varying success. Rotary kilns and auger reactors tumble or mix the material to ensure even heating, while fluidized bed reactors suspend fine plastic particles in a hot gas, enabling almost instantaneous heat transfer and thus, very short residence times.

Feedstock Characteristics

The type and preparation of the plastic feedstock dramatically affect processing time.

Plastics like Polyethylene (PE) and Polypropylene (PP) pyrolyze cleanly at specific temperatures. Materials like PET require different conditions and can be more complex. More importantly, the physical form matters: finely shredded plastic flakes have a much larger surface area and heat up far faster than dense, un-shredded bales.

Operating Temperature

Pyrolysis reactions are governed by kinetics, meaning higher temperatures lead to faster reactions. Increasing the temperature from 450°C to 550°C can significantly shorten the required residence time.

However, simply raising the temperature is not always better, as it also changes the composition of the output products.

Understanding the Trade-offs: Speed vs. Quality

Optimizing for speed alone can compromise the efficiency and economic viability of the entire process.

The Risk of Incomplete Pyrolysis

If the residence time is too short or heat transfer is poor, the plastic may not fully convert. This results in a char residue that is still rich in hydrocarbons, significantly lowering your liquid oil yield and creating a less valuable solid by-product.

The Impact on Product Yield

The combination of temperature and residence time dictates the final product slate.

Fast pyrolysis (high temperature, short residence time) tends to "crack" the long polymer chains into smaller molecules, producing more gas and lighter, lower-viscosity oil. Slower pyrolysis (lower temperature, longer residence time) often yields heavier, waxier oils and less gas.

Energy Consumption and Throughput

While a continuous system is much faster in terms of residence time, its overall throughput must justify its higher capital cost and complexity. A long batch cycle might seem inefficient, but it can be more energy-efficient and cost-effective for smaller-scale operations if designed properly to minimize heat loss.

Matching the Process to Your Goal

The "right" duration depends entirely on your operational objectives. To make an informed decision, you must align the process parameters with your desired outcome.

- If your primary focus is maximizing liquid fuel from mixed plastics: Aim for a continuous process with a residence time of 20-60 minutes at moderate temperatures (450-550°C) to ensure complete conversion without excessive cracking to gas.

- If your primary focus is high-throughput chemical recycling: A fast pyrolysis process like a fluidized bed reactor, with residence times measured in seconds or minutes at higher temperatures (>600°C), is ideal for breaking down polymers into basic chemical feedstocks like monomers.

- If your primary focus is a decentralized or smaller-scale operation: A batch system with an 8-12 hour cycle is often the most practical choice. Your focus should be on optimizing the heating and cooling cycle for energy efficiency and ensuring consistent feedstock preparation.

Ultimately, understanding the variables that control pyrolysis duration empowers you to move beyond a simple question of time and toward designing a truly effective system.

Summary Table:

| System Type | Typical Duration | Key Characteristics |

|---|---|---|

| Batch Reactor | 8 - 24 hours | Processes material in discrete loads; includes heating, reaction, and cooling phases. |

| Continuous Reactor | 20 - 90 minutes (residence time) | Constant feed and product removal; ideal for high-volume industrial use. |

| Fluidized Bed Reactor | Seconds - minutes | Ultra-fast heat transfer; best for chemical recycling into monomers. |

Ready to Optimize Your Plastic Pyrolysis Process?

At KINTEK, we specialize in advanced lab equipment and consumables tailored for pyrolysis research and development. Whether you're scaling from batch to continuous systems or optimizing feedstock preparation, our expertise can help you achieve higher yields, better product quality, and greater efficiency.

Let's build a solution that matches your goals. Contact our experts today to discuss how KINTEK can support your laboratory's pyrolysis innovation.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time