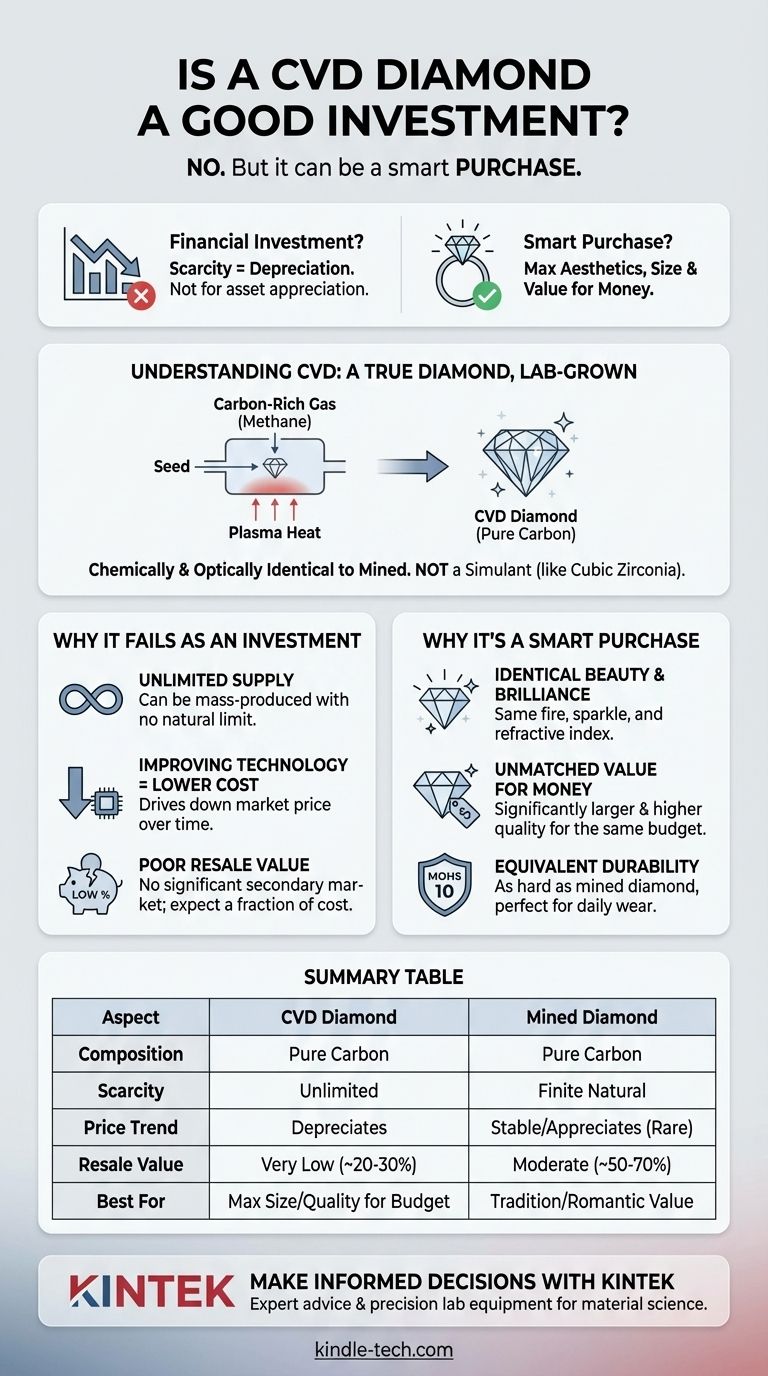

In short, no. A CVD diamond is not a good financial investment in the traditional sense. Because they can be created in a laboratory with ever-improving technology, they lack the key ingredient for asset appreciation: scarcity. Their value is unlikely to increase over time and will almost certainly depreciate once purchased.

The critical distinction to make is between an investment and a purchase. While a CVD diamond fails as a financial investment meant to grow in value, it can be an exceptionally smart purchase for someone prioritizing aesthetics, size, and value for money in their jewelry.

Understanding the CVD Diamond

What It Is: A True Diamond, Made in a Lab

A CVD (Chemical Vapor Deposition) diamond is chemically, physically, and optically identical to a mined diamond. Both are pure carbon crystallized in an isometric cubic structure.

The process begins with a thin "seed" of a diamond slice placed in a vacuum chamber. The chamber is filled with carbon-rich gases (like methane) and heated to extreme temperatures, creating a plasma. This process causes carbon atoms to break from the gas and deposit onto the seed, growing a real diamond crystal layer by layer.

What It Isn't: A Simulant

It is crucial to distinguish a lab-grown diamond from a diamond simulant. A simulant, like Moissanite (silicon carbide) or Cubic Zirconia, only mimics the look of a diamond. A CVD diamond is a diamond, just with a different origin story.

Why CVD Diamonds Fail as a Financial Investment

The Principle of Scarcity

The value of traditional investments like precious metals or mined diamonds is fundamentally tied to their natural rarity. There is a finite supply of diamonds within the Earth.

CVD diamonds have no such supply constraints. They can be produced in virtually unlimited quantities, with manufacturing becoming faster and cheaper over time.

The Impact of Technology

As CVD manufacturing technology improves, the cost of production falls. This downward pressure on cost translates directly to a downward pressure on market price. An asset whose price is expected to decrease over the long term is the antithesis of a sound investment.

The Reality of the Resale Market

There is no significant secondary market for lab-grown diamonds that provides a return on the initial purchase price. If you try to sell a CVD diamond, you should expect to receive a small fraction of what you paid. Retailers purchase them at wholesale prices that are continuously falling, leaving no incentive to buy back used stones at a high price.

The Case for CVD Diamonds as a Smart Purchase

While a poor investment, a CVD diamond is often a superior choice for a personal purchase, especially for an engagement ring or other fine jewelry.

Identical Beauty and Brilliance

To the naked eye, even for a trained jeweler, a high-quality CVD diamond is indistinguishable from a high-quality mined diamond. They exhibit the same fire, brilliance, and sparkle because they have the same refractive index and chemical structure.

Unmatched Value for Money

This is the primary advantage of CVD diamonds. For the same budget, you can acquire a lab-grown diamond that is significantly larger and of higher quality (in terms of cut, color, and clarity) than a natural diamond equivalent.

Equivalent Hardness and Durability

With a Mohs hardness of 10, a CVD diamond is just as hard and durable as a mined diamond. It is perfectly suited for the daily wear and tear an engagement ring endures, and it will not become cloudy or scratch more easily over time.

Understanding the Trade-offs

The "Investment" Myth of Natural Diamonds

It is important to be objective: for the average consumer, even natural diamonds are rarely a good financial investment. The price paid at a retail jeweler includes significant markups. When reselling, you are unlikely to recoup the full retail price, especially in the short term. Only the most exceptionally rare and significant natural diamonds see true investment-grade appreciation.

The Lack of a Geological Story

A mined diamond carries a story of being formed deep within the Earth over billions of years. For some, this geological history and "romance" are an essential part of its value. A CVD diamond, created in a lab over a few weeks, does not share this narrative.

Making the Right Choice for Your Goal

Ultimately, the "right" diamond depends entirely on your primary motivation.

- If your primary focus is a long-term financial asset: You should avoid buying any consumer-grade diamond, whether lab-grown or natural, and consider traditional investment vehicles instead.

- If your primary focus is maximizing the size and visual beauty of your diamond for a set budget: The CVD lab-grown diamond is the logical and unequivocally superior choice.

- If your primary focus is the tradition, romanticism, and geological origin of your stone: You must choose a natural diamond, but do so with the understanding that you are paying a significant premium for its story, not for superior physical properties.

By separating the idea of a financial investment from the value of a personal purchase, you can confidently choose the diamond that truly aligns with your goals.

Summary Table:

| Aspect | CVD Diamond (Lab-Grown) | Mined Diamond |

|---|---|---|

| Chemical Composition | Pure Carbon (Identical) | Pure Carbon (Identical) |

| Scarcity | Unlimited Supply | Finite Natural Supply |

| Price Trend | Depreciates Over Time | Generally Stable/Appreciates (Rare Stones) |

| Resale Value | Very Low (20-30% of Purchase) | Moderate (50-70% of Purchase) |

| Best For | Maximum Size/Quality for Budget | Traditional/Romantic Value |

Make an Informed Decision with KINTEK

Whether you're researching diamond alternatives for industrial applications or seeking guidance on lab equipment for material science, KINTEK has the expertise and products to support your needs. As specialists in laboratory equipment and consumables, we help researchers and professionals make informed decisions about the materials they work with every day.

Let us help you achieve your goals:

- Get expert advice on lab-grown material applications

- Explore our range of precision laboratory equipment

- Find the right tools for your research or production needs

Contact our specialists today to discuss how KINTEK can support your laboratory requirements with reliable equipment and technical expertise.

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- CVD Diamond Domes for Industrial and Scientific Applications

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- How do lab-grown diamonds compare to natural diamonds? Uncover the Truth About Origin, Price, and Value

- What are the limitations of diamonds? Beyond the Myth of Perfection

- What are the applications of microwave plasma? From Diamond Synthesis to Semiconductor Fabrication

- What is a microwave plasma reactor? Unlock Precision Synthesis of High-Performance Materials

- Which lab grown diamond process is best? Focus on Quality, Not the Method