In short, no. A Diamond-Like Carbon (DLC) coating is not scratch-proof, but it is exceptionally scratch-resistant. It represents one of the highest levels of surface hardness available for consumer products like watches and tools, dramatically reducing the risk of everyday scratches. However, it is not invincible and can be damaged by materials harder than itself or by significant impact.

The core misconception is viewing DLC as an indestructible shield. In reality, it is an extremely hard, thin layer applied to a softer base metal. Its true value lies in its ability to resist the vast majority of daily wear and tear, not in providing absolute immunity to all forms of damage.

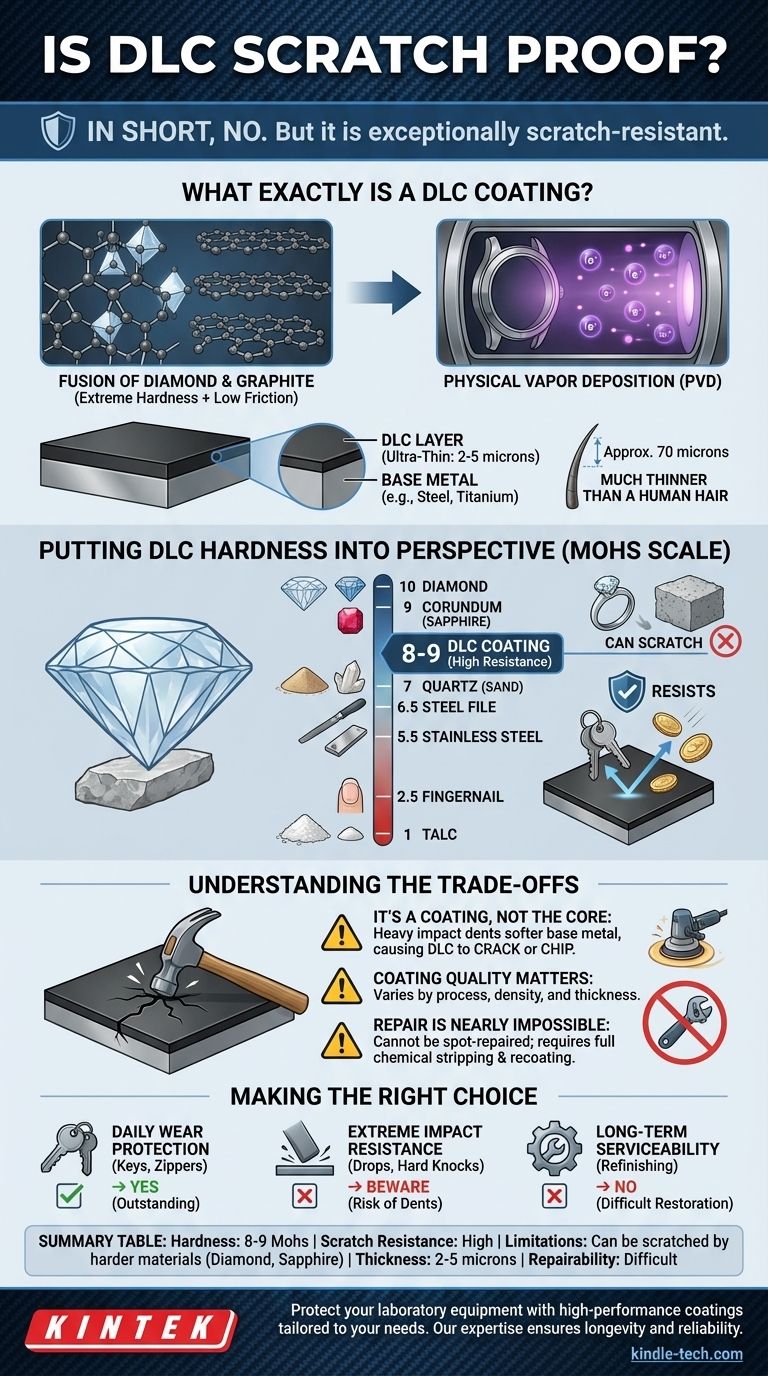

What Exactly is a DLC Coating?

To understand its durability, you first need to understand what it is. DLC is not a type of paint or a simple finish; it's a sophisticated material bonded to the surface of an object.

A Fusion of Diamond and Graphite

DLC is a class of amorphous carbon material that displays some of the unique properties of natural diamond. It is created by depositing a film of carbon atoms that have a mix of diamond-like (hard) and graphite-like (slick) chemical bonds.

This combination gives the coating its two signature properties: extreme hardness and a low coefficient of friction (slipperiness).

Applied as an Ultra-Thin Layer

DLC is applied using a high-tech process called Physical Vapor Deposition (PVD). Inside a vacuum chamber, the base object (like a steel watch case) is bombarded with carbon ions, which bond to the surface atom by atom.

This creates a layer that is incredibly dense and well-adhered, but it is important to remember it is still a thin coating, typically only 2 to 5 microns thick (a human hair is about 70 microns thick).

Putting DLC Hardness into Perspective

The term "hard" is relative. The best way to understand DLC's resistance is to compare it to other common materials.

The Mohs Scale of Hardness

Geologists use the Mohs scale to rate a mineral's ability to resist being scratched. It runs from 1 (Talc) to 10 (Diamond). A material can only be visibly scratched by another material that is harder than it on this scale.

For reference, your fingernail is about a 2.5, a steel file is around a 6.5, and quartz (a component of sand and granite) is a 7.

Where DLC Sits on the Scale

A high-quality DLC coating typically has a hardness of around 8 to 9 on the Mohs scale.

This is why it is so effective. It is significantly harder than stainless steel (~5.5-6), titanium (~6), and most common objects you might encounter, such as keys, coins, and door frames.

What Can Actually Scratch DLC?

A DLC coating can be scratched by any material that is harder than it is. This includes silicon carbide (a common abrasive in sandpaper and concrete), corundum (sapphire, ruby), and, of course, diamond.

A hard scrape against a rough brick wall, a concrete surface, or a diamond ring could permanently scratch the coating.

Understanding the Trade-offs and Limitations

While exceptional, DLC is not without its limitations. Understanding these is key to managing your expectations.

It's a Coating, Not the Core Material

The single most important limitation is that the underlying metal is still soft. While the DLC surface can resist a scratch, it cannot prevent a dent.

A sharp, heavy impact can dent the softer steel or titanium beneath the coating. Because the DLC layer is extremely hard and inflexible, this dent can cause the coating to crack, chip, or flake at the point of impact.

Coating Quality and Thickness Matter

Not all DLC applications are created equal. The specific process, the density of the carbon bonds, and the thickness of the coating all contribute to its final durability.

An inexpensive, poorly applied DLC finish may not offer the same level of scratch resistance or adhesion as a multi-layered coating from a high-end manufacturer.

Repairing DLC is Nearly Impossible

Unlike a brushed stainless steel surface that can be refinished to remove scratches, a damaged DLC coating cannot be spot-repaired.

If a DLC surface is significantly scratched or chipped, the only solution is to have the entire part chemically stripped and completely recoated, which is an expensive and specialized process.

Making the Right Choice for Your Goal

Deciding if a DLC-coated product is right for you means weighing its superior scratch resistance against its cost and limitations.

- If your primary focus is daily wear and tear protection: DLC is an outstanding choice, effectively shrugging off the vast majority of incidental scratches from keys, desks, and zippers.

- If your primary focus is extreme impact resistance: Be aware that while the surface is hard, a severe drop or impact can still dent the underlying metal and cause the coating to chip.

- If your primary focus is long-term serviceability: A standard stainless steel or titanium finish is highly practical, as it can be refinished or polished to remove signs of wear, whereas damaged DLC is very difficult to restore.

Ultimately, DLC offers a premier level of scratch resistance for everyday life, but understanding it as a high-performance coating—not an invincible armor—is the key to its long-term appreciation.

Summary Table:

| Aspect | DLC Coating Characteristic |

|---|---|

| Hardness (Mohs Scale) | 8 to 9 |

| Scratch Resistance | High (resists keys, coins, steel) |

| Limitations | Can be scratched by harder materials like diamond or sapphire |

| Coating Thickness | 2 to 5 microns (ultra-thin) |

| Repairability | Difficult; often requires full recoating |

Protect your laboratory equipment with high-performance coatings tailored to your needs. KINTEK specializes in lab equipment and consumables, offering durable solutions that withstand daily wear and tear. Whether you need scratch-resistant surfaces or specialized coatings for tools, our expertise ensures longevity and reliability. Contact us today to enhance your lab's efficiency and equipment durability!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- CVD Diamond Cutting Tool Blanks for Precision Machining

- High-Purity Titanium Foil and Sheet for Industrial Applications

People Also Ask

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- Is diamond coating worth it? Maximize Component Life and Performance

- What is CVD diamond coating? Grow a Super-Hard, High-Performance Diamond Layer

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers